cnc machining production This automated parts carousel not only catches and collects machined parts from a CNC machine tool but also sorts the parts in bins attached to a rotating table. . Production Machining’s September 2024 technology . Knockouts are small openings in electrical boxes that provide space for electrical cables/wiring to enter and exit the electrical box. In electrical boxes made out of metal, knockouts are circular and approximately quarter-size.

0 · what is cnc in manufacturing

1 · how does cnc machine work

2 · cnc manufacturing technology

3 · cnc machining operations

4 · cnc machining manufacturing process

5 · cnc machining manufacturing

6 · cnc machining capabilities

7 · cnc machine fabrication

What Are Steel Coils? Steel coils are long, thin sheets of steel that are used in a variety of applications. They are produced by rolling steel at high temperatures and can be .

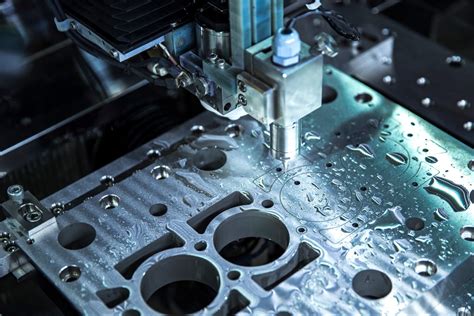

Production CNC machining process involves leveraging CNC technology to attain high-scale production of different metal and non-metal parts and components with tight tolerances, superior quality, higher dimensional .CNC machining is a digital manufacturing technology: it produces high-accuracy parts with excellent physical properties directly from a CAD file. Due to the high level of automation, CNC is price-competitive for both one-off custom parts . The online extension of Production Machining magazine and the most comprehensive site available for high volume precision machining professionals. This automated parts carousel not only catches and collects machined parts from a CNC machine tool but also sorts the parts in bins attached to a rotating table. . Production Machining’s September 2024 technology .

Computer numerical control (CNC) is used by modern machine tools to program and control movement of key machine components during machining operations. . Production Machining’s September 2024 technology showcase includes some of the latest technology from Expand Machinery, Paperless Parts, Monaghan Tooling Group, Walter USA and more. . Understanding these elements helps anticipate the financial commitment involved in CNC machining services and parts production: Batch Size - Typically, the larger the quantity of parts ordered, the lower the cost per unit. This is due to the spread of setup costs over a larger number of parts, achieving economies of scale. .

CNC Machining: Beyond Algorithmic Precision: While CNC machining provides the backbone of high-volume production, its effectiveness hinges on far more than simply pre-programmed instructions. Sophisticated CAM software, coupled with advanced toolpath optimization algorithms, is critical for minimizing machining time and tool wear.A collection of products, editorial, news, and more about Star CNC Machine Tool Corp. from Production Machining. The Precision Machined Parts Industry's Leading Information Resource . Star CNC Machine Tool’s SV-20R Swiss-type lathe features a gang slide and an opposing turret with a 360-degree programmable B axis for front and back .

Production Machining’s September 2024 technology showcase includes some of the latest technology from Expand Machinery, Paperless Parts, Monaghan Tooling Group, Walter USA and more. . User-friendly inspection software for CNC machining centers was shown at IMTS 2024 monitoring measurements between and after machining while performing SPC .PMT provides CNC machining services to a variety of industries across the United States. Quality oriented and customer focused, PMT can get the job done right.CNC machining’s nature—removing only the necessary material—already helps reduce waste, but additional efforts are being made to minimize scrap and conserve resources during production. Many facilities also invest in energy-efficient machinery and equipment to lower their carbon footprint and operational costs.

The wide range of available materials compatible with CNC machining makes the production of a final part even faster than traditional manufacturing. CNC machining remains the preferred method used when traditional manufacturing demands are harder to reach as the parts to be produced are made up of intricate and critical dimensional points. .CNC Machining Production Manager jobs. Sort by: relevance - date. 600+ jobs. CNC Machining Manager. Modus Advanced, Inc. 4.8. Livermore, CA 94550. 0,000 - 5,000 a year. Full-time. Day shift +2. Easily apply. Prepares a weekly production schedule and prioritizes production.Learn about CNC machining processes in the comprehensive guide by Dassault Systèmes, enabling precise and efficient production of complex parts. . Germany is a world leader in the manufacturing sector and has a predominant share in the production and use of European CNC machines. The United States seems to have stagnated in recent years .

CNC MACHINING , MILLING MACHINIG , CNC TURNING PRODUCTION AND PROTOTYPE . Our Services. . Catering to specialized and niche requirements, we offer small-scale production runs. Whether you're an individual needing a few parts or a business requiring a limited run, we ensure the highest quality in every piece we produce. . Automation in CNC machining allows for high production with minimal labour, reducing costs and errors. Additionally, CNC technology is at the forefront of the fourth industrial revolution, integrating digital technologies to enhance collaboration and efficiency. Whether for small batches or mass production, CNC machines offer a faster and more .

Production CNC machining is a cutting-edge manufacturing process that has changed the production of high-quality components for the better with its precision and efficiency. The importance of production CNC machining lies in its capacity to reliably produce high-quality parts, even when manufacturing large quantities. .

Mike Medeiros, production manager at North Easton Machine Co., has been advocating CNC Swiss lathes for years, attempting to persuade his local high school’s administration to add the technology to the school’s . As a result, CNC machining is a perfect production process for making end effectors with smooth surface finish. Custom Jigs and Fixtures: Essential for Robot Operations. custom jigs and fixtures. Custom jigs and . If the production line use edge tracing by vision, after filming, coordinate calculate and CNC bed moving just only cost 10 seconds to finish, and the time of machining is standardization.

what is cnc in manufacturing

1 - Haas EC-500 Horizontal Machining Center; 2 - Haas VF-5 Vertical Machining Centers; 2 - Haas VF-6-50 Taper Vertical Machining Centers; 2 - Haas VF-3 Vertical Machining Centers; 2 - Haas CNC Vertical TM-2 Mills; 1 - Haas VF-4 VMC w/40 Station Tool Magazine, 50" x 20" x 25" 4th Axis; 1 - 2005 Haas VF5/50 CNC VMC 10,000 rpm, 4th Axis indexer

A CNC machine that operates on wood CNC machines typically use some kind of coolant, typically a water-miscible oil, to keep the tool and parts from getting hot. A CNC metal lathe with the door open.. In machining, numerical control, also called computer numerical control (CNC), [1] is the automated control of tools by means of a computer. [2] It is used to operate tools such .Engelbrecht Manufacturing is dedicated to the art of precision machining. Request Quote. Your Partner. . and exotic materials using the latest in CAD/CAM and CNC technologies. What We Do. Precision CNC Machining Production Manufacturing Prototype Development Assembly of Component Parts Full Service Inspection Project Management. Production Machining’s September 2024 technology showcase includes some of the latest technology from Expand Machinery, Paperless Parts, Monaghan Tooling Group, Walter USA and more. . User-friendly inspection software for CNC machining centers was shown at IMTS 2024 monitoring measurements between and after machining while performing SPC .

Rapid Prototyping. Rapid Axis’s CNC machines are great for prototype manufacturing.Since the machine runs quickly and creates highly accurate parts, you can have a functional prototype created in days.. CNC machines tend to make pieces in production-grade metals or plastics, so the prototype you get will be fully operational.

"Discover how CNC machining is revolutionizing metal part production. From 3D CAD designs to flawless metal components, this video covers the essential techn. Introduction. CNC machining is a subtractive manufacturing process involving different automated cutting tools to reshape a material. It uses computer-controlled processes to achieve precision cutting, reshaping, and parts fabrication. The main advantage of this process is its high precision and repeatability, which makes it a mainstay in various industries, especially . This flexibility enables CNC machining to improve production efficiency and reduce costs in the face of diverse production needs. CNC machine tools can achieve highly automated production. By using computer numerical control (CNC) systems, the operation of machine tools can be accurately controlled, achieving unmanned production. .In conclusion, CNC machining has revolutionized the production process by offering several advantages. From superior precision and automation to versatility and rapid prototyping, CNC machining can transform your business and take it to new heights. CNC machining is a game-changer for manufacturing by delivering consistent, high-quality results.

Batch production is a method whereby the components of an item are produced in separate stages on separate machines to create different batches of products. Using CNC machines for batch production can streamline the workflow because of the reliability, accuracy, and speed of CNC-based manufacturing. The Benefits CNC machining offers immediate cost .

how does cnc machine work

Shop transform 21.34-in x 24.17-in 1-Basin White Freestanding Laundry Sink with Faucet in the Utility Sinks department at Lowe's.com. TRANSFORM offers a line of sleek modern style all-in-one laundry cabinets. Our freestanding pre-assembled cabinet with .

cnc machining production|cnc machining operations