automotive sheet metal $143.99

$11.04

0 · replacement sheet metal body parts

1 · replacement auto body sheet metal

2 · automotive sheet metal near me

3 · automotive replacement sheet metal

4 · auto sheet metal replacement

5 · aftermarket sheet metal car parts

6 · aftermarket sheet metal body parts

7 · aftermarket automotive sheet metal parts

One crucial component of your electrical system is the breaker box on outside of house. The breaker box outside house is responsible for regulating the flow of electricity to your home, ensuring that your residential appliances and devices .

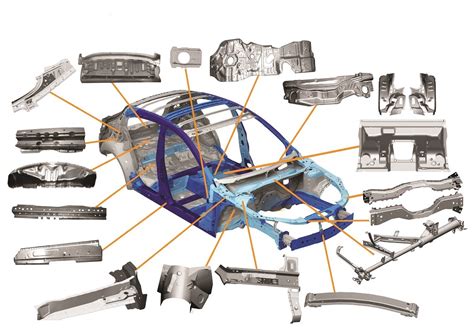

Revitalize your restoration projects with high-quality replacement sheet metal from Eastwood. Whether you’re repairing a classic 1957 Chevy or a 2007 truck, we offer OEM-quality panels . Learn how sheet metal is used in various automotive applications, such as body-in-white, frames, closure panels, and structural components. Explore the different materials, .No matter the condition of your vehicle, OPGI has the Sheet Metal & Body Panels you need to boost performance and get you back on the road. We currently carry 1000 Sheet Metal & Body ..99

.99.99Looking for Sheet Metal Parts for your automotive? Then shop at 1A Auto for aftermarket, replacement Sheet Metal for many cars, trucks and SUVs, at a great price. Visit us online or . Automotive sheet metal fabrication is a set of manufacturing techniques with high precision that enables the automotive industry to grow and produce quality parts while supporting its innovation. Making an informed .

Raybuck carries sheet metal for a variety of auto repairs. Need to patch a small hole in a floor pan or bed floor, click here to order cold rolled flat steel now..775.28.96

replacement sheet metal body parts

replacement auto body sheet metal

The first step is cutting away the damaged metal, then overlapping and clamping the new patch to the old fender, making sure it is accurately positioned. With the patch panel clamped in place, a scriber is used to mark the old fender for trimming. After scribing, the patch is unclamped and the fender is trimmed precisely on the scribed line in . MIG welding sheet metal. When welding thin metal, the main objective is to avoid warping, burn-through and excessive heat-affected zones while still ensuring the weld has enough mechanical strength for the application. Short-circuit transfer MIG (short arc), TIG and pulsed TIG welding processes provide the most control over the heat to address . MIG welding benefits. MIG can be used to weld most common automotive metals, including carbon steel, stainless steel and aluminum, and the process is much more forgiving on thin metals. MIG welding enables DIY welders to make most types of welds for automotive repair on material from 24-gauge up to 1/4-inch thick.Welding is an essential skill for both beginners and experienced professionals in the ever-evolving automotive repair and customization field. This comprehensive guide is a gateway to mastering automotive welding, which involves various techniques and materials. It covers everything from intricate bodywork to sturdy frame repairs, providing you .

Lower melting point. The silicon bronze rod’s lower melting point makes it ideal for joining together thin sheet metal, galvanized steel, and nuts and bolts, too. It’s nice for sheet metal work because the lower melting temps means less heat, which equals less warping when compared to TIG with, say, an ER70 rod. The following basic MIG welding settings are for welding steel with solid wire. Joint design, position and other factors affect results and settings. When good results are achieved, record the parameters. Material thickness determines amperage. As a guideline, each .001 inch of material thickness requires 1 amp of output: .125 inch = 125 amps.

The thicker the metal, the less noticeable the effect. This can be a very important consideration for rust repair on a car's body. If you burn it in full boar without any thought or control, you will have a poor result in the final product. In the previous “Making Metal” article, I discussed heat control in sheet metal welding. If you have .RMD reduces the welding current to create a consistent metal transfer, allowing for easy puddle control and paving the way for consistent, uniform welds — with less spatter and fewer poor fitups. Industry Applications: Open root, pipe, plate and vessel, heat exchangers, sheet metal fabrication, auto body, furniture, commercial kitchen products120/240V, single-phase power input. Auto-Set™ technology makes the welder easy to use; LCD interface for simple setup. Includes welder, 6.5-ft. power cord, 10-ft. MDX™ MIG gun, 13-ft. stick electrode holder, 12.5-ft. TIG torch, 20-ft. foot pedal, 10-ft. work cable, 2-lb. spool of 0.8-mm steel wire, regulators, and consumables. Download Spec .

Tip 2: Choose the best filler metal alloy possible. There are many factors to consider when selecting the best filler metal for welding aluminum sheet metal. These include the base metal alloy, service temperature and environment, formability and more. The two most common aluminum filler metals are 4043 and 5356. The first step is cutting away the damaged metal, then overlapping and clamping the new patch to the old fender, making sure it is accurately positioned. With the patch panel clamped in place, a scriber is used to mark the old fender for trimming. After scribing, the patch is unclamped and the fender is trimmed precisely on the scribed line in . MIG welding sheet metal. When welding thin metal, the main objective is to avoid warping, burn-through and excessive heat-affected zones while still ensuring the weld has enough mechanical strength for the application. Short-circuit transfer MIG (short arc), TIG and pulsed TIG welding processes provide the most control over the heat to address .

MIG welding benefits. MIG can be used to weld most common automotive metals, including carbon steel, stainless steel and aluminum, and the process is much more forgiving on thin metals. MIG welding enables DIY welders to make most types of welds for automotive repair on material from 24-gauge up to 1/4-inch thick.Welding is an essential skill for both beginners and experienced professionals in the ever-evolving automotive repair and customization field. This comprehensive guide is a gateway to mastering automotive welding, which involves various techniques and materials. It covers everything from intricate bodywork to sturdy frame repairs, providing you .

Lower melting point. The silicon bronze rod’s lower melting point makes it ideal for joining together thin sheet metal, galvanized steel, and nuts and bolts, too. It’s nice for sheet metal work because the lower melting temps means less heat, which equals less warping when compared to TIG with, say, an ER70 rod.

The following basic MIG welding settings are for welding steel with solid wire. Joint design, position and other factors affect results and settings. When good results are achieved, record the parameters. Material thickness determines amperage. As a guideline, each .001 inch of material thickness requires 1 amp of output: .125 inch = 125 amps. The thicker the metal, the less noticeable the effect. This can be a very important consideration for rust repair on a car's body. If you burn it in full boar without any thought or control, you will have a poor result in the final product. In the previous “Making Metal” article, I discussed heat control in sheet metal welding. If you have .RMD reduces the welding current to create a consistent metal transfer, allowing for easy puddle control and paving the way for consistent, uniform welds — with less spatter and fewer poor fitups. Industry Applications: Open root, pipe, plate and vessel, heat exchangers, sheet metal fabrication, auto body, furniture, commercial kitchen products

automotive sheet metal near me

120/240V, single-phase power input. Auto-Set™ technology makes the welder easy to use; LCD interface for simple setup. Includes welder, 6.5-ft. power cord, 10-ft. MDX™ MIG gun, 13-ft. stick electrode holder, 12.5-ft. TIG torch, 20-ft. foot pedal, 10-ft. work cable, 2-lb. spool of 0.8-mm steel wire, regulators, and consumables. Download Spec .

automotive replacement sheet metal

You need the right type of glue when working with metal and fabric. The appropriate glue choice depends on the project's materials, and how and where the finished craft will be used. Epoxy glue, hot glue and glue dots work well to create a bond between metal and fabric.

automotive sheet metal|replacement auto body sheet metal