cobots in manufacturing cnc machine tending Collaborative robots (cobots) are automation tools that can perform machine tending tasks and work alongside operators, helping fill persistent labor shortages while offering high-quality, consistent outputs 24/7. $240.99

0 · tending cnc machine cobot

1 · robot machine tending system

2 · moving cobot between cnc machines

3 · machine tending machine robots

4 · machine tending automation

5 · cobot machine tending machine

6 · cobot for cnc machines

The majority of house keys are made out of a combination of nickel and silver, or brass. While most keys come in either silver or brown colouring, they are able to be plated in assorted colours as well.

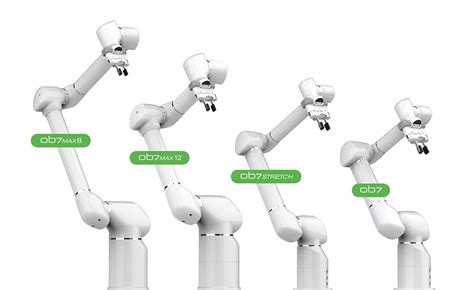

Collaborative robots (cobots) are automation tools that can perform machine tending tasks and work alongside operators, helping fill persistent labor shortages while offering high-quality, consistent outputs 24/7.Cobot machine tending refers to collaborative robots, or cobots, helping out human workers with automated machine loading and unloading. Instead of replacing human workers, cobots work .Collaborative robots (cobots) are automation tools that can perform machine tending tasks and work alongside operators, helping fill persistent labor shortages while offering high-quality, consistent outputs 24/7.

Cobot machine tending refers to collaborative robots, or cobots, helping out human workers with automated machine loading and unloading. Instead of replacing human workers, cobots work side by side with them to handle repetitive, mundane tasks like feeding materials into CNC machines or removing finished parts.

Automated CNC machine tending automates feeding raw parts into the CNC and removing the machined product—all without a human involvement. It improves productivity, reliability, and accuracy. Most importantly, it frees up your operators for more fulfilling tasks. By using a cobot, you can quickly and easily automate the work of loading, running, and unloading CNC machines. This reduces loading errors, speeds up production, and might even help fill in gaps in your labor force, among other benefits. Keep reading to . Machine tending robots are useful for loading and unloading workpieces in CNC turning operations, ensuring the machine operates with maximum overall equipment effectiveness. Their use in this area highlights their versatility and ability to adapt to different manufacturing processes.

Experience an immediate productivity boost by automating machine tending processes with our cobots. Thanks to our best-in-class repeatability, speed and motion, you can accelerate production with faster and more precise machine tending, resulting in increased throughput and operational efficiency.Companies that machine parts not only face labor shortages and productivity issues but are now challenged by customer demands to handle low-volume, high-mix work. A very flexible and safe solution is mounting a cobot to a mobile platform like an autonomous mobile robot (AMR). Cobots take on the tedious, repetitive, and error-prone tasks that workers find monotonous, or that contribute to bottlenecks in production. By taking on the machine tending process, cobots maximize spindle utilization and free up operators to handle other valuable tasks. Do you want to upgrade your machine tending processes with collaborative robot? Here's our guide to properly choosing and integrating them.

cobots) can operate alongside skilled workers, in a shared workspace. Cobots feature internal sensors, controls, and safety protoc. ease of use, cobots are particularly well suited for machine tending. Operators can program cobots very quickly, and upon deployment, cobots deliver higher throughput, consist.

tending cnc machine cobot

Collaborative robots (cobots) are automation tools that can perform machine tending tasks and work alongside operators, helping fill persistent labor shortages while offering high-quality, consistent outputs 24/7.Cobot machine tending refers to collaborative robots, or cobots, helping out human workers with automated machine loading and unloading. Instead of replacing human workers, cobots work side by side with them to handle repetitive, mundane tasks like feeding materials into CNC machines or removing finished parts.

steel router table cabinet

Automated CNC machine tending automates feeding raw parts into the CNC and removing the machined product—all without a human involvement. It improves productivity, reliability, and accuracy. Most importantly, it frees up your operators for more fulfilling tasks. By using a cobot, you can quickly and easily automate the work of loading, running, and unloading CNC machines. This reduces loading errors, speeds up production, and might even help fill in gaps in your labor force, among other benefits. Keep reading to . Machine tending robots are useful for loading and unloading workpieces in CNC turning operations, ensuring the machine operates with maximum overall equipment effectiveness. Their use in this area highlights their versatility and ability to adapt to different manufacturing processes.

Experience an immediate productivity boost by automating machine tending processes with our cobots. Thanks to our best-in-class repeatability, speed and motion, you can accelerate production with faster and more precise machine tending, resulting in increased throughput and operational efficiency.Companies that machine parts not only face labor shortages and productivity issues but are now challenged by customer demands to handle low-volume, high-mix work. A very flexible and safe solution is mounting a cobot to a mobile platform like an autonomous mobile robot (AMR). Cobots take on the tedious, repetitive, and error-prone tasks that workers find monotonous, or that contribute to bottlenecks in production. By taking on the machine tending process, cobots maximize spindle utilization and free up operators to handle other valuable tasks.

robot machine tending system

Do you want to upgrade your machine tending processes with collaborative robot? Here's our guide to properly choosing and integrating them.

moving cobot between cnc machines

steel storage cabinets above 6 feet seismic ancho

steel sheet metal for sale near me

The finishing process not only enhances the appearance of the parts, but it also impacts their durability, corrosion resistance, and functionality. In this article, we'll explore the various kinds of finishing for CNC machined car parts.

cobots in manufacturing cnc machine tending|tending cnc machine cobot