cnc machine foundation requirements ☑ Foundation. You must put your machine on a solid and stable concrete foundation. The standard 6" (150 mm) concrete floor in industrial buildings is usually sufficient. However, heavy . Junction boxes are crucial for connecting and protecting the electrical connections within a solar system. They provide a secure and organized space for connecting solar panels and include components like diodes to prevent reverse current flow.

0 · machine tools foundation design

1 · machine foundation specifications

2 · machine foundation requirements

3 · machine foundation design

4 · concrete machine foundation design standards

5 · cnc machining requirements

6 · cnc flooring machine requirements

7 · basic foundation requirements

Sheet Metal Workers fabricate, assemble, install, and repair sheet metal products and equipment, such as ducts, control boxes, drainpipes, and furnace casings.

machine tool suppliers worldwide for 30 years, designing foundations for large milling machines. Over that time span, we have developed a checklist to ensure the foundation design meets the needs of the owner and also meets the requirements of the machine tool supplier.

The following general requirements of machine foundations shall be satisfied and results checked prior to detailing the foundations. 1. The foundation should be . Size, complexity and needed results from the machine all go into the needs for the foundation. All machine tool builders recommend for worst case. I know of over 50,000lb .

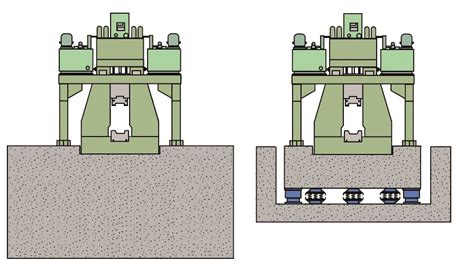

☑ Foundation. You must put your machine on a solid and stable concrete foundation. The standard 6" (150 mm) concrete floor in industrial buildings is usually sufficient. However, heavy . Machines having long beds or runways need a dedicated fountation to resist the deflections of moving masses over the lineral bearings. Some machines are intended for .

Building a strong and stable machine foundation is crucial for the successful operation and longevity of any industrial equipment. A well-designed foundation not only provides structural support and stability but also helps to minimize . For some machines – especially precision machine tools – foundation design should begin as follows. Obtain a foundation reference drawing and guidelines from the .In this section, we will discuss the step-by-step approach to calculating the ideal thickness for a CNC machine foundation. We will explore methods such as structural analysis, static and . Building and designing a good foundation is critical to maintaining a consistently high-quality workpiece over a long period of time. The foundation ensures machine alignment and repeatable geometry by providing stiffness to .

On average, a concrete thickness of 6 to 12 inches (150 to 300 mm) is recommended for most CNC machines. However, for very heavy or high-precision machines, a thickness of up to 24 inches (600 mm) may be necessary.

machine tool suppliers worldwide for 30 years, designing foundations for large milling machines. Over that time span, we have developed a checklist to ensure the foundation design meets the needs of the owner and also meets the requirements of the machine tool supplier.The following general requirements of machine foundations shall be satisfied and results checked prior to detailing the foundations. 1. The foundation should be able to carry the superimposed loads without causing shear or crushing failure. 2. The settlements should be within the permissible limits. 3. Size, complexity and needed results from the machine all go into the needs for the foundation. All machine tool builders recommend for worst case. I know of over 50,000lb machines sitting on thick pads that rise and fall millimeters with local tides.

☑ Foundation. You must put your machine on a solid and stable concrete foundation. The standard 6" (150 mm) concrete floor in industrial buildings is usually sufficient. However, heavy and complex machines, such as Large-Frame mills and UMCs, may require a 12" (300 mm) concrete foundation, to ensure accurate geometry. Refer to these .

Machines having long beds or runways need a dedicated fountation to resist the deflections of moving masses over the lineral bearings. Some machines are intended for massive workpieces and if installed on inferior subsoil they require a siutable foundation to keep its alignments in spev.Building a strong and stable machine foundation is crucial for the successful operation and longevity of any industrial equipment. A well-designed foundation not only provides structural support and stability but also helps to minimize vibrations . For some machines – especially precision machine tools – foundation design should begin as follows. Obtain a foundation reference drawing and guidelines from the machine builder.In this section, we will discuss the step-by-step approach to calculating the ideal thickness for a CNC machine foundation. We will explore methods such as structural analysis, static and dynamic load analysis, and consulting engineering guidelines.

Building and designing a good foundation is critical to maintaining a consistently high-quality workpiece over a long period of time. The foundation ensures machine alignment and repeatable geometry by providing stiffness to the machine tool. On average, a concrete thickness of 6 to 12 inches (150 to 300 mm) is recommended for most CNC machines. However, for very heavy or high-precision machines, a thickness of up to 24 inches (600 mm) may be necessary.machine tool suppliers worldwide for 30 years, designing foundations for large milling machines. Over that time span, we have developed a checklist to ensure the foundation design meets the needs of the owner and also meets the requirements of the machine tool supplier.

mexico metal fabricators

The following general requirements of machine foundations shall be satisfied and results checked prior to detailing the foundations. 1. The foundation should be able to carry the superimposed loads without causing shear or crushing failure. 2. The settlements should be within the permissible limits. 3. Size, complexity and needed results from the machine all go into the needs for the foundation. All machine tool builders recommend for worst case. I know of over 50,000lb machines sitting on thick pads that rise and fall millimeters with local tides.☑ Foundation. You must put your machine on a solid and stable concrete foundation. The standard 6" (150 mm) concrete floor in industrial buildings is usually sufficient. However, heavy and complex machines, such as Large-Frame mills and UMCs, may require a 12" (300 mm) concrete foundation, to ensure accurate geometry. Refer to these . Machines having long beds or runways need a dedicated fountation to resist the deflections of moving masses over the lineral bearings. Some machines are intended for massive workpieces and if installed on inferior subsoil they require a siutable foundation to keep its alignments in spev.

Building a strong and stable machine foundation is crucial for the successful operation and longevity of any industrial equipment. A well-designed foundation not only provides structural support and stability but also helps to minimize vibrations . For some machines – especially precision machine tools – foundation design should begin as follows. Obtain a foundation reference drawing and guidelines from the machine builder.In this section, we will discuss the step-by-step approach to calculating the ideal thickness for a CNC machine foundation. We will explore methods such as structural analysis, static and dynamic load analysis, and consulting engineering guidelines.

Building and designing a good foundation is critical to maintaining a consistently high-quality workpiece over a long period of time. The foundation ensures machine alignment and repeatable geometry by providing stiffness to the machine tool.

machine tools foundation design

Steel gauge uses a retrogressive scale, which means the lower the gauge number, the thicker (and stronger) the steel will be. Cheap garage cabinets found in a lot of retailers often use steel gauges in the 20-24 range.

cnc machine foundation requirements|machine foundation design