job process operation in sheet metal work What are the Sheet Metal Operations? 1. Blanking: 2. Punching: 3. Piercing: 4. Cut-off: 5. Parting off: 6. Notching: What is the importance of Notching in Sheet Metal work? 7. Bending: What is Sheet Metal? A piece of metal that can be .

Wholesale deals often include discounts, after-sale support, and customization options to suit specific manufacturing requirements. Partnering with a renowned supplier guarantees timely delivery and reliable machinery performance. Haven't found what you want?

0 · working with sheet metal

1 · types of sheet metal operations

2 · sheet metal work process

3 · sheet metal production process

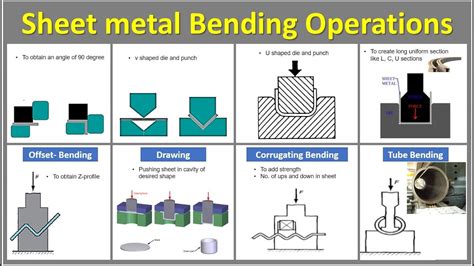

4 · sheet metal operations diagram

5 · sheet metal operations

6 · sheet metal drawing operations

7 · sheet metal design process

Online sheet metal fabrication service. Get custom parts delivered in just a few days—upload STEP or DXF files for instant pricing!

The main challenge of sheet metal design is to choose the right process and the right order for each step. The process and order depend on factors such as the material properties, the .

22 gauge 4x8 sheet metal

Sheet metal processing is a vast concept, covering several machining operations done to metal sheets. Since the topic is too broad, most people think the overall process only boils down to a single function. However, .In this article, you’ll learn the various types of sheet metal operations with their diagrams. The common types of sheet metal operations are shearing, blanking, punching, piercing, trimming, drawing, embossing, bending, and squeezing . Read on and explore the different sheet metal operations to develop a comprehensive understanding of each. Shearing. One of the oldest and most straightforward techniques in sheet metal working is shearing. This .

working with sheet metal

SHEET METALWORKING. Cutting and forming thin sheets of metal usually performed as cold working. Sheet metal = 0.4 (1/64) to 6 mm (1/4in) thick. Plate stock > 6 mm thick. Advantage. .What are the Sheet Metal Operations? 1. Blanking: 2. Punching: 3. Piercing: 4. Cut-off: 5. Parting off: 6. Notching: What is the importance of Notching in Sheet Metal work? 7. Bending: What is Sheet Metal? A piece of metal that can be .

The fundamental goal of sheet metal forming procedures is to give the metal sheets particular geometrical modifications while preserving their structural integrity. The common types of sheet metal operations are shearing, .Understanding the steps in the sheet metal stamping process demonstrates how high-quality components are produced, guiding businesses toward informed decisions and efficient .In this article we will discuss about the sheet metal manufacturing process and its operation types. Introduction to Sheet Metal Work: Most of the sheet metal work is done on presses where a .GST Rate for Sheet Metal Fabrication Job Work . The GST rate for sheet metal fabrication job work is determined based on the HSN code classification. The current GST rate for services under HSN code 9988 is 18%. This rate is applicable to all types of sheet metal fabrication job work, including cutting, bending, shaping, welding, and assembling.

types of sheet metal operations

sheet metal work process

Sheet metal works Sheet metal work is deforming process of Manufacturing withthis process metal sheets are designed. to different shape applying of pressure. With application of different tools, equipment and Machine. A sheet .

179 Sheet Metal Fabrication jobs available on Indeed.com. Apply to Quality Assurance Inspector, Metal Fabricator, Quality Assurance Analyst and more! . bending machine operation, turret punch operations, and sheet metal fabrication . or non-conformities in .

In bending and embossing of sheet metal, the female die is replaced with rubber pad Rubber pad forming (RPF) is a metalworking process where sheet metal is pressed between a die and a rubber block, made of polyurethane. Under pressure, the rubber and sheet metal are driven into the die and conform to its shape, forming the part.

Municipal building codes and contracting license boards also regulate certain sheet metal work activities that impact public safety. . Take measurements and create project plans to determine required materials and sequence of operations; Set up, operate, adjust, and maintain cutting machinery like shears, press brakes, and CNC machines to cut .Oversee daily operations in the sheet metal fabrication process (e.g., cutting, bending, welding, stamping). Ensure adherence to safety standards and quality control procedures. Manage and maintain manufacturing equipment, ensuring maximum uptime and reliability. Assist in the selection and installation of new machinery.lesson: job operation sheets objectives 1. to identify the concept and purpose of job operation sheets as an instructional tool. 2. to identify the advantages of using job operation sheets. 3. to analyze a given job for operations, procedure, and -key points. 4. to list the steps required to develop job operation sheets. 5.Guide the recruiter to the conclusion that you are the best candidate for the sheet metal worker job. It’s actually very simple. . for Metal Work (Job Element 81-C) Ability to Interpret Instructions, Specifications, etc. (includes blueprint reading). (Job Element 75-A) . Note discrepancies between operation sheet data, blueprints and tape .

Types of Sheet Metal Operations. Below are the types of sheet metal operations: Shearing Operations. The Shearing operation is cut in a straight line across a strip, sheet, or bar. It leaves a lean edge on the piece of metal that is sheared or cut. In this operation, a sheet metal workpiece is placed or kept between two dies from one end. Starts machine and observes machine operation to reposition work piece, change dies, or adjust machine settings for multiple or .

Sheet metal is a thin piece of metal between 0.006 and 0.25 inches thick. Sheet metal can be cut, bent, and stretched into various shapes through forming and cutting operations. Common forming operations include bending, deep drawing, and roll forming. Common cutting operations include shearing, blanking, punching, notching, and slitting.For - Sheet metal production engineer is responsible for: Producing sheet metal products according to manufacturing orders received. Creating a production plan to deliver the required products within the required timelines.

Drawing is a sheet-metal-forming operation used to make cup-shaped, box-shaped, or other complex-curved and concave parts by placing a piece of sheet metal over a die cavity and pushing the metal into the cavity with a punch: True False Coining is a bulk deformation process also used in sheet-metal work in which fine details in a die are impressed into the top and .Get contact details and address of Sheet Metal Components Job Work, Sheet Metal Job Work, Sheet Metal Fabrication Job Work firms and companies. IndiaMART. Get Best Price. Shopping. Sell. Help. Messages. IndiaMART > Sheet Metal . Iskcon Process. Sector 23, Faridabad Plot No-56A, Sohna Road, Sanjay Colony, Sector-23, Sector 23 . Discover the top 10 CAD/CAM software solutions for sheet metal and tube processing. Boost productivity, streamline workflows, and create advanced parts with industry-leading design and manufacturing tools. Find the .

29 Sheet Metal jobs available in Augusta, GA on Indeed.com. Apply to Sheet Metal Mechanic, General Maintenance, Millwright and more! . Utilizing 3D CAD models and engineering prints to fabricate mechanical components using standard machine-shop operations (sheet metal, . Candidate must have transportation and able to get to work on time .

sheet metal production process

Ensuring the maintenance of tools and equipment used in sheet metal operations . Sheet Metal Foreman Job Description Template . Job Title: Sheet Metal Foreman; Work Environment: . Problem-solving skills to effectively troubleshoot issues that may arise during the fabrication process. Physical stamina and strength to handle heavy tools .Sheet Metal jobs now available in Penang. Sheet Metal Mechanic, Quality Control Inspector, Chargeman A4/bo and more on Indeed.com . Process engineering in sheet metal: 1 year (Required). To generate Work instruction for the sheet metal operation, designed of jig and fixture and tools based .Sheet Metal Contractor Operations Manager Jobs. In this article, we’ll look at the job information you need to know, including an example of Sheet Metal Contractor Operations Manager daily duties, a typical work day in the role & team meetings you would attend. The foregoing literature review reveals that only a few research and development works have been carried out in the area of automation of strip-layout design for sheet metal work on progressive dies. Most of the works are concentrated on process planning for sheet metal blanking and piercing operations.

Job Description . Job Title: Structure Maintainer – Group D (Sheet Metal). Job ID: 4973. Location: Various. Full/Part Time: Full-Time Regular/Temporary: Regular Job Information: First Date of Posting: November 4, 2024 Last Date of Filing: Until Filled Authority: TA Department: Subway Division/ Unit: Maintenance of Way/Infrastructure Reports to: Supervision

Guide the recruiter to the conclusion that you are the best candidate for the sheet metal job. It’s actually very simple. . set-up information and/or related instructions to understand appropriate work process and quality requirements for completed product . Observes machine operation to detect work-piece defects or machine malfunction Generally, Sheet metal cutting refers to splitting a single metal sheet into two or more pieces.But, it also involves the removal of unwanted parts from a sheet using shear force, heat, or any other form of energy. The cutting process requires high pressure at the cutting position, which can fracture the sheet from the designated area to create the desired shape.Sr. Director of Sheet Metal Operations. Employment Type: Direct Hire Location: Nashville, TN Pay: 0,000 - 0,000, 15% AIP Bonus Schedule: Full-time, On-site Travel: 0-20% to job sites or office locations Relocation Assistance: Available Benefits: Comprehensive benefits package including medical, dental, vision, life, accident, and disability insurance, as well as a 401(k) plan.

Shearing is a trimming operation that involves cutting a sheet of metal along a straight line. It’s a relatively simple and fast process that results in clean, straight edges. The Shearing Process Detailed. Measurement and Marking: The sheet metal is measured, and the cut lines are marked. Setup: The metal sheet is placed into the shearing .10,272 Sheet Metal Work jobs available on Indeed.com. Apply to Sheet Metal Mechanic, Metal Fabricator, Press Brake Operator and more! . You should have previous experience with press machine operation, whether through steel manufacturing or sheet metal work. Employer Active 4 days ago. Sheet Metal Mechanic. U.S. Coast Guard.Hiring An Operations Manager. In this article, we’ll look at a job description for a Sheet Metal Contractor Operations Manager, job requirements, the common job interview questions to ask someone applying for this role, follow-up questions to ask your potential new hire and excellent answers that candidates give to Sheet Metal Contractor Operations Manager job interview .

sheet metal operations diagram

Buy - JUNCTION BOX online at $9.45 from Hollywood Wholesale Electric - Your one stop store for all your electrical and lighting needs.If you’re looking for top-quality CNC machining in Edinburgh delivered by qualified professionals then choose G&M Precision! Get in touch with us by sending an enquiry using .

job process operation in sheet metal work|sheet metal work process