sheet metal drafting Reading a sheet metal drawing involves identifying the details of the design of sheet metal parts, such as dimensions, geometry, material specifications, and any special requirements. Meanwhile, detailing this . Our CNC turning services produce high-quality cylindrical parts. Learn about the advantage of using turning machine processes and get a free quote today! 866-765-9191

0 · simple sheet metal drawings

1 · sheet metal layout drawings

2 · sheet metal drawing for practice

3 · sheet metal drafting standards

4 · sheet metal drafting pdf

5 · sheet metal basic drawing

6 · metal sheet mechanical drawings

7 · deep drawing in sheet metal

Custom Copper Stamped Parts. Winco Stamping provides short run and .

metal box replacement chesapeake

This article endeavors to demystify the intricate domain of sheet metal drawing, focusing specifically on its more specialized variant, deep drawing. We’ll delve into its foundational principles, the technical aspects, and myriad .See document 10-0005, Blah Drawing & Drafting Standards and Practices, for the proper setup of a sheet metal drawing. For door panels, front panels, interior panels, and racks see document .

This article will provide a series of key sheet metal design and fabrication guidelines to help engineers and designers understand how to maximize the use of the characteristics of metal sheets, ensuring the feasibility . Pattern Development: Sheet Metal Level 1. Line E. Brian Coey. Download this book. This book covers all three forms of layout as well as geometric construction. It introduces the learner to the techniques used in . Reading a sheet metal drawing involves identifying the details of the design of sheet metal parts, such as dimensions, geometry, material specifications, and any special requirements. Meanwhile, detailing this . 1. Sheet Metal Drafting. —Sheet metal drafting is merely the application of the principles of ordinary mechanical drawing to objects which, for the purposes of drawing, lack .

metal box spring full size

Discover the top 5 free CAD software for sheet metal design, including FreeCAD, Onshape, and Fusion 360. Unleash your creativity with these powerful, easy-to-use programs that streamline your sheet metal projects. . Amazon.com: Sheet Metal Drafting: 9780070051263: Betterley, Melvin L.: Books. Skip to main content.us. Delivering to Nashville 37217 Update location Books. Select the department you want to search in. Search Amazon. . Follow these best practices next time you create a sheet metal fabrication drawing to help your shop turn the project around quickly: 1. List part numbers, not just the part name. Part names are great, but it’s helpful to .Our pre-fabrication design and drafting team works tirelessly to get you the right sheet metal shop drawing with all the essentials addressed. Fabrication Drawings &Estimation Get comprehensive 2D fabrication drawings with coding and listing along with estimates for accurate bid values.

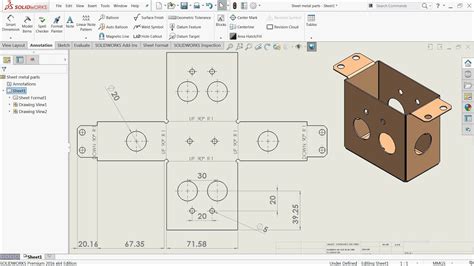

Now create a drawing of the sheet metal part. Start with an isometric view of the folded model, and then add a view of the unfolded model. Click Options (Standard toolbar).; On the System Options tab, click Drawings > Display Style.; Under Tangent edges, select Visible, and click OK.; Click Make Drawing from Part/Assembly (Standard toolbar) or File > Make Drawing from Part, . Sheet metal drawing standards seem to hard to come by as I have been searching a little bit lately as well. I understand that bend allowances vary greatly by material, tooling, and process. What I am looking for is standard accepted language or a format for describing information on a flat pattern view. For example, one of our designers has .

Insert Bends or “Convert to Sheet Metal” features. When designing with sheet metal, it is important to think about the best approach to model or design a part. At times, it may appear quicker to use non-sheet metal features (boss-extrude, etc.), and then insert bends or convert to sheet metal. However, these options are problematic Sheet metal drafting by Betterley, Melvin L. Publication date 1978 Topics Sheet-metal work -- Patternmaking, Mechanical drawing Publisher New York : Gregg Division, McGraw-Hill Collection internetarchivebooks; inlibrary; printdisabled Contributor Internet Archive Language English Item SizeThis also means that tolerances in the title block of a drawing may be unnecessarily restrictive for certain dimensions and angles, while very appropriate for others. Critical Dimensions Sheet Metal Forming – Outside dimension should be used unless the inside dimension is critical. You can create a flatten (unbended) sheet metal view in the drafting. To create a flatten view in drafting: Activate the “Sheet Metal” application. Click the “Flat Pattern” command. (In the sheet metal application) Select the face on the sheet metal model to specify a reference face for flattening.

rests. Straight lines connecting the points established upon these perpendiculars are the true lengths from which the pattern is developed. The pattern is started by drawing a Horizontal line such as line 1-A of Fig. 294.With A as a center and a radius equal to the hypotenuse of section A to 2, an arc is drawn bearing away from point 1. This is intersected by . Sheet metal drafting Bookreader Item Preview . Sheet-metal work Publisher New York [etc.] McGraw-Hill book company, inc. Collection library_of_congress; americana Contributor The Library of Congress Language English Item Size 416.6M . x, 236 p. 24 cm Addeddate

Sheet-metal pattern drafting and shop problems, Bookreader Item Preview . Sheet-metal work -- Patternmaking Publisher Peoria, Ill., Manual Arts Press Collection library_of_congress; fedlink; americana Contributor The Library of Congress Language English Item Size 334.0M

Sheet Metal Drafting Using SolidWorks teaches basic drafting techniques and sheet metal drafting using SolidWorks. The text begins with simple solid models and proceeds to complex sheet metal assemblies with drawings, exploded views, parts lists, revisions, and other items related to the field. The material is presented so that users can learn .a) The Sheet Metal and Air Conditioning Contractor’s National Association (“SMACNA”) provides its product for informational purposes. b) The product contains “Data” which is believed by SMACNA to be accurate and correct but the data, including all information, ideas and expressions therein, is provided strictly “AS IS”, with all . Drafting Standards, GD&T & Tolerance Analysis . Sheet Metal Part GDT Thread starter nmine; Start date Jun 5, 2024; Status Not open for further replies. Jun 5, 2024 #1 nmine Mechanical. Jul 7, 2023 . I have a large sheet metal enclosure base that has lots of panel mount connector holes. How do you go about applying GDT when one datum setup . Reviewer: aldinary - favorite favorite favorite favorite - March 20, 2011 Subject: Sheet-metal Pattern Drafting . good . 3,582 Views . 9 Favorites. 1 Review . DOWNLOAD OPTIONS download 1 file . ABBYY GZ download. download 1 file . CHOCR .

With four Solidworks licences and extensive expertise in sheet metal design, our Solidworks Sheet Metal accredited drafters possess the skills and knowledge to create precise and tailored designs. Replication of Complex Parts. To replicate intricate and challenging parts accurately, we utilise a state-of-the-art 3D scanner. Excerpt from Sheet Metal Drafting: Prepared in the Extension Division of the University This text on Sheet Metal Drafting was prepared especially for correspondence-study instruction in the Extension Division of the University of Wisconsin. It is also admirably adapted as a text book for Vocational, Evening, and Part-time Schools. In the manufacturing industry, the sheet metal process is common, and sheet metal parts are used in many different industries, including consumer products, appliances, aircraft, and the automotive and aerospace sectors. Sheet Metal Operations. Following are the 9 different types of sheet metal operations: Shearing Operations; Blanking Operations

Sheet metal is harder to dimension than machined parts primarily because the bending is less accurate. Sheet metal shops tell me they can do ±.015" (0.4mm) from a bend. I would guess that the punching that flat layout approaches the accuracy of machining. You need to do tolerance stacks with your realistic tolerances. After drawing a profile, it should be divided into sixteen equal spaces, and extension lines from each division carried to the apparent miter line. The divisions of the profile should be numbered, and the intersections of the apparent miter line lettered as shown in Fig. 101.

i worked at a large company with a world-class sheet metal manufacturing plant attached. we were required to provide a flat pattern view with each sheet metal drawing, but dimensions were not required. the purpose here was to "prove" that the part in the drawing could be made from a single non-overlapping sheet of metal. basically it was a . For fabricators striving to achieve standard quality and efficiency, investing in professional sheet metal CAD drafting services is not merely a choice, but a strategic necessity. By doing so, fabricators can build their projects on a foundation of precision, thereby reducing errors, streamlining production, and ultimately delivering superior . 30. Drawing Sheet metal forming to make cup‑shaped, box‑shaped, or other complex‑curved, hollow‑shaped parts Sheet metal blank is positioned over die cavity and then punch pushes metal into opening Products: beverage cans, ammunition shells, automobile body panels Also known as deep drawing (to distinguish it from wire and bar drawing) ©2007 John .

Ideally, a single 3D model for sheet metal products should have comprehensive design features to ensure clear design intent communication. For example, a typical sheet metal part model can have more than 20 features. This shows the need for an efficient CAD platform like SolidWorks with specific sheet metal design drafting features.Our sheet metal drawing and drafting services accelerate design-to-engineering cycle while focusing on the accuracy of design communication across stakeholders. 2D CAD Drafting. 2D detail drawings with BOMs; Part-mix consideration; K-factor calculation; Bend radius/calculations as per gauge tables;

simple sheet metal drawings

sheet metal layout drawings

sheet metal drawing for practice

Parking - GKDMETALFABRICS | Architectural Metal Mesh Manufacturer

sheet metal drafting|deep drawing in sheet metal