bend radius formula sheet metal Use this page to choose bend values for sheet metal that are both manufacturable and meet your needs.

Racing canoes are rigged with aluminum braces that allow a seat to be mounted on an internal frame system so they can be adjusted front to back as well. I really like the idea of having adjustable seats to accomodate conditions and different paddling partners.

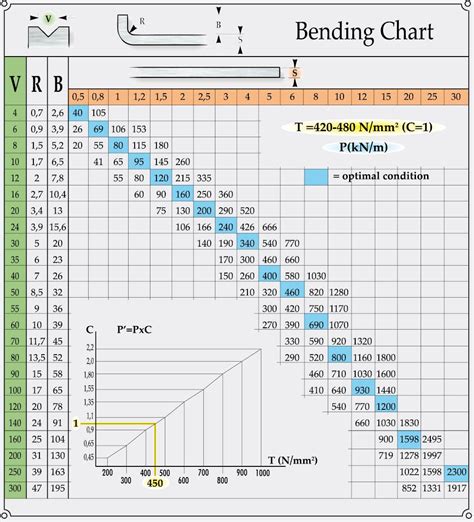

0 · sheet metal bending chart

1 · sheet metal bending angle chart

2 · sheet metal bend radius standard

3 · sheet metal bend radius calculator

4 · sheet metal bend calculation formula

5 · calculate bend radius for steel

6 · blank size calculator sheet metal

7 · bend radius sheet metal chart

This utility tool storage box measures 14.25" x 36" x 10.63" and is easy to assemble with a unique snap fit design. Montezuma provides intuitive tool and garage storage solutions that allow consumers to securely and efficiently organize their lives.

The sheet metal bending radius is a critical value in sheet metal drawing that can be difficult to determine during the actual processing. This radius is dependent on the material thickness, the pressure of the press brake .

The bend allowance chart is an essential resource for professionals working with sheet metal fabrication. It provides a comprehensive listing of key parameters such as material thickness, bending radius, bending angle, bend . • Enter the precise sheet thickness and desired inner bend radius. • The calculator will instantly provide the K-factor, Y-factor, and neutral layer . You can derive the Bend Allowance (BA) by using the K , Bend .

Sheet Metal Bend Radius Guidelines Here are a few key concepts to know about designing for sheet metal Brackets, covers, cabinets, chassis, electrical enclosures.

Use this page to choose bend values for sheet metal that are both manufacturable and meet your needs.Sheet Bending Calculator is used to calculate sheet bending allownace, bend deductions, sheet bending plate raw sizebend angle and radius for use in SolidWorks. The bend allowance values can then be used for an entire part, individual bends, or to populate a bend table. K-factor K-factor is a single value .

More Than One Sheet Metal Bending Formula. Press brake technicians can use various formulas to calculate bend functions. For instance, in this article we have used the following for outside setback: OSSB = [Tangent (degree of . The sheet metal bending radius is a critical value in sheet metal drawing that can be difficult to determine during the actual processing. This radius is dependent on the material thickness, the pressure of the press brake machine, and the width of .

The bend allowance chart is an essential resource for professionals working with sheet metal fabrication. It provides a comprehensive listing of key parameters such as material thickness, bending radius, bending angle, bend allowance, and bend deduction values for common materials.

• Enter the precise sheet thickness and desired inner bend radius. • The calculator will instantly provide the K-factor, Y-factor, and neutral layer position, crucial for accurate bending calculations. • Input the required bend angle in degrees.You can derive the Bend Allowance (BA) by using the K , Bend Radius (R), Bend Angle (A) and Material Thickness using the formula below. BA=Pi*(R+K*T)*A/180. In this formula: K represents the K-factor. BA is the bend allowance. A is the bend angle. R .Sheet Metal Bend Radius Guidelines Here are a few key concepts to know about designing for sheet metal Brackets, covers, cabinets, chassis, electrical enclosures.Use this page to choose bend values for sheet metal that are both manufacturable and meet your needs.

Sheet Bending Calculator is used to calculate sheet bending allownace, bend deductions, sheet bending plate raw size

sheet metal bending chart

bend angle and radius for use in SolidWorks. The bend allowance values can then be used for an entire part, individual bends, or to populate a bend table. K-factor K-factor is a single value which can be used to represent how sheet metal bends fold/unfold over .

Bend allowance and deduction formulas are used for air bending. Different results will occur if coining or bottom bending the material. EMPIRICAL FORMULA: Bend allowance = (.0078 x MT + .017453 x BR) x A° MT = Material thickness BR = bend radius to . More Than One Sheet Metal Bending Formula. Press brake technicians can use various formulas to calculate bend functions. For instance, in this article we have used the following for outside setback: OSSB = [Tangent (degree of . The sheet metal bending radius is a critical value in sheet metal drawing that can be difficult to determine during the actual processing. This radius is dependent on the material thickness, the pressure of the press brake machine, and the width of .

The bend allowance chart is an essential resource for professionals working with sheet metal fabrication. It provides a comprehensive listing of key parameters such as material thickness, bending radius, bending angle, bend allowance, and bend deduction values for common materials.

• Enter the precise sheet thickness and desired inner bend radius. • The calculator will instantly provide the K-factor, Y-factor, and neutral layer position, crucial for accurate bending calculations. • Input the required bend angle in degrees.You can derive the Bend Allowance (BA) by using the K , Bend Radius (R), Bend Angle (A) and Material Thickness using the formula below. BA=Pi*(R+K*T)*A/180. In this formula: K represents the K-factor. BA is the bend allowance. A is the bend angle. R .Sheet Metal Bend Radius Guidelines Here are a few key concepts to know about designing for sheet metal Brackets, covers, cabinets, chassis, electrical enclosures.Use this page to choose bend values for sheet metal that are both manufacturable and meet your needs.

Sheet Bending Calculator is used to calculate sheet bending allownace, bend deductions, sheet bending plate raw sizebend angle and radius for use in SolidWorks. The bend allowance values can then be used for an entire part, individual bends, or to populate a bend table. K-factor K-factor is a single value which can be used to represent how sheet metal bends fold/unfold over .

sheet metal bending angle chart

$15.99

bend radius formula sheet metal|sheet metal bending chart