bending thick sheet metal Sheet Metal Bending Calculation. Bend Allowance (BA) BA = [(0.017453 × Inside radius) + (0.0078 × Material thickness)] × Bend angle, which is always complementary. The length of the neutral axis is calculated as a . Large complex machined parts are the foundation of what make Openex into a leading supplier to Large OEM’s. Our State of the Art manufacturing facility is able to turn parts with a max OD of 22000mm and up to 6500mm tall. Our Cranes can lift up to 450 Tons.

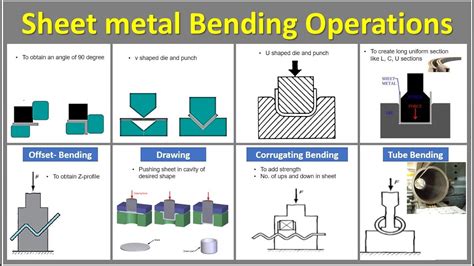

0 · types of bending sheet metal

1 · sheet metal bending standards

2 · sheet metal bending near me

3 · sheet metal bending guidelines

4 · sheet metal bending chart

5 · problems with sheet metal bending

6 · bending sheet metal by hand

7 · bending galvanized sheet metal

Whether you need parts created for agriculture and storage applications, sheet metal parts fabrication for heavy trucks, metal fabrication for medical equipment or anything else, we’ll be able to provide you with high-quality, reliable service.

The experience in actual sheet metal processing shows that when the general plate thickness is not greater than 6mm, the inner radius of the sheet metal bend can be directly .

Sheet Metal Bending Calculation. Bend Allowance (BA) BA = [(0.017453 × Inside radius) + (0.0078 × Material thickness)] × Bend angle, which is always complementary. The length of the neutral axis is calculated as a .

The minimum sheet metal bending height should be calculated as 2 times the thickness of the sheet metal plus the bending radius, i.e., H ≥ 2t + R. As illustrated in the accompanying figure, if the bending height is too low, the .

Bending sheet metal by hand is a manageable task if the piece of sheet metal is small and thin enough to handle. Learn how to bend sheet .

The solution is to have a radius on the tool that you’ll be using to bend the metal. This will prevent cracking or weak spots. Here’s a good rule of thumb for most materials: The inside bend radius should be equal to the thickness of the .

What ensures the perfect bend in sheet metal? This article unpacks five crucial factors that can make or break your sheet metal bending projects, covering essential aspects like minimum bending radius, bending . Minimum bend radii are typically specified in terms of sheet thickness (t) such as 1t, 2t, 3t, etc. We recommend a minimum bend radius of 1t for all sheet metal parts. Thus the smallest radius of any bend in a sheet . That’s why when bending thick or high-tensile metals, you need to abide by a minimum inside bend radius. This will minimize the effects of strain hardening and cracking at the bend. From basic concepts to advanced techniques, this guide covers everything you need to know about sheet metal bending. Learn about the different bending methods, tools, and tips to achieve accurate and high-quality results.

The experience in actual sheet metal processing shows that when the general plate thickness is not greater than 6mm, the inner radius of the sheet metal bend can be directly used as the radius when bending. Sheet Metal Bending Radius. When the plate thickness is greater than 6mm and less than 12mm, the bending radius in the plate is generally 1 . Sheet metal bending can be done using many methods. We discuss those along with springback, bend allowances, k factor, design tips etc. Sheet Metal Bending Calculation. Bend Allowance (BA) BA = [(0.017453 × Inside radius) + (0.0078 × Material thickness)] × Bend angle, which is always complementary. The length of the neutral axis is calculated as a bend allowance, taken at .

The minimum sheet metal bending height should be calculated as 2 times the thickness of the sheet metal plus the bending radius, i.e., H ≥ 2t + R. As illustrated in the accompanying figure, if the bending height is too low, the sheet metal is prone to deformation and twisting during the bending process , leading to suboptimal part shape and . Bending sheet metal by hand is a manageable task if the piece of sheet metal is small and thin enough to handle. Learn how to bend sheet metal so you can complete home and hobby projects easily without using a sheet metal brake.The solution is to have a radius on the tool that you’ll be using to bend the metal. This will prevent cracking or weak spots. Here’s a good rule of thumb for most materials: The inside bend radius should be equal to the thickness of the material that you’re forming. What ensures the perfect bend in sheet metal? This article unpacks five crucial factors that can make or break your sheet metal bending projects, covering essential aspects like minimum bending radius, bending height, hole margins, bending line position, and the importance of positioning holes.

Minimum bend radii are typically specified in terms of sheet thickness (t) such as 1t, 2t, 3t, etc. We recommend a minimum bend radius of 1t for all sheet metal parts. Thus the smallest radius of any bend in a sheet should be at least equal to the thickness of the sheet.

cnc machine shop baltimore

That’s why when bending thick or high-tensile metals, you need to abide by a minimum inside bend radius. This will minimize the effects of strain hardening and cracking at the bend.

From basic concepts to advanced techniques, this guide covers everything you need to know about sheet metal bending. Learn about the different bending methods, tools, and tips to achieve accurate and high-quality results. The experience in actual sheet metal processing shows that when the general plate thickness is not greater than 6mm, the inner radius of the sheet metal bend can be directly used as the radius when bending. Sheet Metal Bending Radius. When the plate thickness is greater than 6mm and less than 12mm, the bending radius in the plate is generally 1 .

types of bending sheet metal

Sheet metal bending can be done using many methods. We discuss those along with springback, bend allowances, k factor, design tips etc. Sheet Metal Bending Calculation. Bend Allowance (BA) BA = [(0.017453 × Inside radius) + (0.0078 × Material thickness)] × Bend angle, which is always complementary. The length of the neutral axis is calculated as a bend allowance, taken at . The minimum sheet metal bending height should be calculated as 2 times the thickness of the sheet metal plus the bending radius, i.e., H ≥ 2t + R. As illustrated in the accompanying figure, if the bending height is too low, the sheet metal is prone to deformation and twisting during the bending process , leading to suboptimal part shape and .

Bending sheet metal by hand is a manageable task if the piece of sheet metal is small and thin enough to handle. Learn how to bend sheet metal so you can complete home and hobby projects easily without using a sheet metal brake.The solution is to have a radius on the tool that you’ll be using to bend the metal. This will prevent cracking or weak spots. Here’s a good rule of thumb for most materials: The inside bend radius should be equal to the thickness of the material that you’re forming. What ensures the perfect bend in sheet metal? This article unpacks five crucial factors that can make or break your sheet metal bending projects, covering essential aspects like minimum bending radius, bending height, hole margins, bending line position, and the importance of positioning holes.

sheet metal bending standards

sheet metal bending near me

Tissue lame is a 49% nylon and 51% metallic mixed embossed Japanese tissue lame fabric. This 45" wide fabric has a stunning sheen look and a naturally flowing drape. It is soft to the touch, but features a coarse grain look and texture.

bending thick sheet metal|sheet metal bending chart