electrical junction box knockout sizes The sizing requirements for pull boxes, junction boxes, handhole enclosures, and conduit bodies exist to prevent conductor insulation damage. Those requirements are in 314.28, and they apply to all conductors 4 AWG .

Miller is the first welding equipment manufacturer in the U.S.A. to be registered to the ISO 9001:2000 Quality System Standard. We’ve made installation and operation quick and easy. With Miller you can count on years of reliable service with proper maintenance.

0 · knockout plugs for electrical outlet

1 · knockout plugs for electrical boxes

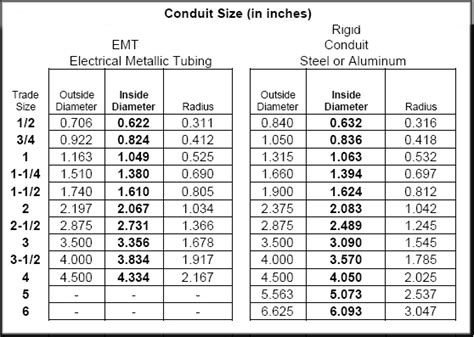

2 · electrical trade size chart

3 · electrical knockout size chart

4 · electrical box knockout sizes chart

5 · electrical box 1 2 knockout

6 · conduit hole saw size chart

7 · conduit fitting hole size chart

The best way to weld galvanized steel, regardless of welding process, is to remove the zinc coating from the joint. This adds two operations: removing the coating and re-spraying or .

Junction boxes have knockouts on top, bottom and sides. Top/bottom knockouts are 2 and 1-1/2 in - sides are 2, 1-1/2, 3/4 and 1/2 in. Photo shows box with components that may also be . A knockout for 1/2" conduit is 7/8", but the outside diameter of a 1/2" EMT fitting is about 3/4". 3/4" knockout is 1-3/32" (close enough to 1-1/8), . Sizes 1/ 2 " thru 6" per proposed revision to NEMA Engineering Bulletin No. 71, Aug. .Pedestal (35" Ht. x 4" Wd. x 4" Dp.) Choose from our selection of junction boxes, including corrosion-resistant washdown enclosures, indoor enclosures, and more. In stock and ready to ship.

Box knockouts are pre-measured to create perfectly sized openings for common conduit sizes, and each takes just a few seconds to remove. They can also be easily reclosed by knockout plugs and knockout seals later. The sizing requirements for pull boxes, junction boxes, handhole enclosures, and conduit bodies exist to prevent conductor insulation damage. Those requirements are in 314.28, and they apply to all conductors 4 AWG .

How do I know what size to order? The electrical industry has common conduit sizes. EKO’s are routinely made for these common sizes. However, EKO tools must be . Section 314.16 specifies the minimum volume size of junction boxes required for various types of electrical conductors. The volume size of a junction box is measured in cubic inches. It is determined based on the number and . These regulations describe in detail the required junction box size, depending on the number and size of conductors and fittings enclosed within the box. You’ll need to calculate both box volume and box fill when determining .How To Find Exact Knockout Size For Conduit? Contractors appreciate panels and enclosures with knockout holes because they can install wires and conduits without making new holes. You don’t have to tolerate smaller knockouts. You can enlarge them to accommodate larger conduits.

Junction boxes have knockouts on top, bottom and sides. Top/bottom knockouts are 2 and 1-1/2 in - sides are 2, 1-1/2, 3/4 and 1/2 in. Photo shows box with components that may also be ordered separately. A knockout for 1/2" conduit is 7/8", but the outside diameter of a 1/2" EMT fitting is about 3/4". 3/4" knockout is 1-3/32" (close enough to 1-1/8), and O.D. of 3/4" fitting is roughly 1". So basically 1/8" for fudging around?Sizes 1/ 2 " thru 6" per proposed revision to NEMA Engineering Bulletin No. 71, Aug. 1976. Both rigid conduit and intermediate metallic conduit are threaded and accept couplings, nuts, and bushings et cetera directly.Pedestal (35" Ht. x 4" Wd. x 4" Dp.) Choose from our selection of junction boxes, including corrosion-resistant washdown enclosures, indoor enclosures, and more. In stock and ready to ship.

Box knockouts are pre-measured to create perfectly sized openings for common conduit sizes, and each takes just a few seconds to remove. They can also be easily reclosed by knockout plugs and knockout seals later.

knockout plugs for electrical outlet

knockout plugs for electrical boxes

The sizing requirements for pull boxes, junction boxes, handhole enclosures, and conduit bodies exist to prevent conductor insulation damage. Those requirements are in 314.28, and they apply to all conductors 4 AWG and larger ( Fig. 1 ). How do I know what size to order? The electrical industry has common conduit sizes. EKO’s are routinely made for these common sizes. However, EKO tools must be ordered for the actual size of the hole, not the conduit size. See conversion chart below: Form Up .

Section 314.16 specifies the minimum volume size of junction boxes required for various types of electrical conductors. The volume size of a junction box is measured in cubic inches. It is determined based on the number and size of conductors within the box.

These regulations describe in detail the required junction box size, depending on the number and size of conductors and fittings enclosed within the box. You’ll need to calculate both box volume and box fill when determining the appropriate size for a junction box. What do these concepts mean?How To Find Exact Knockout Size For Conduit? Contractors appreciate panels and enclosures with knockout holes because they can install wires and conduits without making new holes. You don’t have to tolerate smaller knockouts. You can enlarge them to accommodate larger conduits.Junction boxes have knockouts on top, bottom and sides. Top/bottom knockouts are 2 and 1-1/2 in - sides are 2, 1-1/2, 3/4 and 1/2 in. Photo shows box with components that may also be ordered separately.

A knockout for 1/2" conduit is 7/8", but the outside diameter of a 1/2" EMT fitting is about 3/4". 3/4" knockout is 1-3/32" (close enough to 1-1/8), and O.D. of 3/4" fitting is roughly 1". So basically 1/8" for fudging around?Sizes 1/ 2 " thru 6" per proposed revision to NEMA Engineering Bulletin No. 71, Aug. 1976. Both rigid conduit and intermediate metallic conduit are threaded and accept couplings, nuts, and bushings et cetera directly.Pedestal (35" Ht. x 4" Wd. x 4" Dp.) Choose from our selection of junction boxes, including corrosion-resistant washdown enclosures, indoor enclosures, and more. In stock and ready to ship.

Box knockouts are pre-measured to create perfectly sized openings for common conduit sizes, and each takes just a few seconds to remove. They can also be easily reclosed by knockout plugs and knockout seals later. The sizing requirements for pull boxes, junction boxes, handhole enclosures, and conduit bodies exist to prevent conductor insulation damage. Those requirements are in 314.28, and they apply to all conductors 4 AWG and larger ( Fig. 1 ). How do I know what size to order? The electrical industry has common conduit sizes. EKO’s are routinely made for these common sizes. However, EKO tools must be ordered for the actual size of the hole, not the conduit size. See conversion chart below: Form Up .

Section 314.16 specifies the minimum volume size of junction boxes required for various types of electrical conductors. The volume size of a junction box is measured in cubic inches. It is determined based on the number and size of conductors within the box.

electrical trade size chart

11 gauge sheet metal thickness in inches

Where I weld, in one of my attached garage bays, there is a 50 amp welder receptacle fed by #10 wire from a 30 amp breaker in my electrical service panel . This works well for my 30 amp draw welder - Lincoln MIG Pak 15.

electrical junction box knockout sizes|knockout plugs for electrical outlet