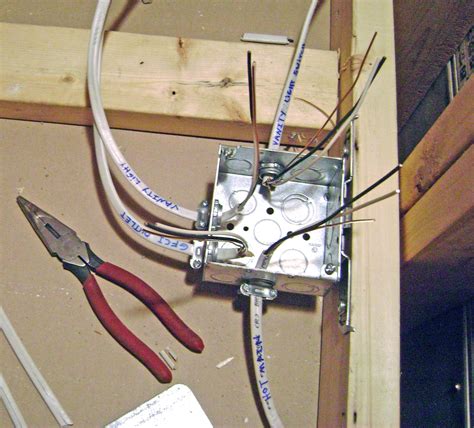

ceiling fan screws for junction box installation There were two screws that were originally "parked" in the box to secure the fan bracket to the "ears" and those screws have been removed and . Simply put, “metal fabrication” is defined as creating products or structures by cutting, bending, and/or assembling metal material. It’s largely considered a value-added process as it consists of putting together actual products or structures from metal raw material.

0 · installing junction box in ceiling

1 · installing ceiling outlet box

2 · installing ceiling fan electrical box

3 · ceiling fan support box installation

4 · ceiling fan retrofit junction box

5 · ceiling fan outlet box installation

6 · ceiling fan junction box adapter

7 · ceiling fan box replacement

What Is Piercing? Piercing is a sheet metal working process in which a tool is used to pierce a round or other shaped holes in sheet metal with no or tiny scrap, in order to obtain the perforated sheet.Photochemical machining (PCM), also known as photochemical milling or photo etching, is a chemical milling process used to fabricate sheet metal components using a photoresist and etchants to corrosively machine away selected areas. This process emerged in the 1960s as an offshoot of the printed circuit board industry. Photo etching can produce highly complex parts with very fine detail .

There were two screws that were originally "parked" in the box to secure the fan bracket to the "ears" and those screws have been removed and .What size screws fit in ceiling fan junction box? The most frequent type of screw used in electric boxes is the 6-32 flathead screw. For ceiling fan junction boxes, however, 8-32 or 10-32 screws are recommended for securing the connection . Installing a ceiling fan junction box is a crucial step in enhancing the ventilation and aesthetics of your living space. This guide will provide you with a comprehensive . Feed the existing wire through the cable clamp in the top of the new metal ceiling fan junction box, slip the box over the saddle screws, and tighten the nuts to clamp the box to the shaft with a nut driver or a deep-well .

Connecting a ceiling fan to a junction box is a manageable task that can be completed with the right tools and safety precautions. By following these step-by-step . There were two screws that were originally "parked" in the box to secure the fan bracket to the "ears" and those screws have been removed and lost. Contact the mfgr and get some new screws, if you want the exact type originally supplied.

Most building codes require ceiling fans to be mounted on special fan-rated boxes made of metal or strong plastic with deep-threaded holes for the mounting screws. The box must be mounted firmly by attaching it directly to a framing member or using a fan-rated brace.

Junction boxes like that one are 8-32. Ground screws are 10-32. Also, you could buy a ceiling hugger style fan instead of a stem mounted one, and fasten it directly to the ceiling with toggle bolts or similar fasteners, instead of just .What size screws fit in ceiling fan junction box? The most frequent type of screw used in electric boxes is the 6-32 flathead screw. For ceiling fan junction boxes, however, 8-32 or 10-32 screws are recommended for securing the connection . Installing a ceiling fan junction box is a crucial step in enhancing the ventilation and aesthetics of your living space. This guide will provide you with a comprehensive understanding of the process, empowering you to tackle this electrical task with confidence. Feed the existing wire through the cable clamp in the top of the new metal ceiling fan junction box, slip the box over the saddle screws, and tighten the nuts to clamp the box to the shaft with a nut driver or a deep-well socket.

Connecting a ceiling fan to a junction box is a manageable task that can be completed with the right tools and safety precautions. By following these step-by-step instructions and addressing any troubleshooting issues, you can enjoy the comfort and style of . In this comprehensive guide, we will provide you with a detailed step-by-step tutorial on how to install a ceiling fan junction box, ensuring a safe and secure installation. Connect the ground wire from the ceiling fan to the green or bare copper wire in the junction box. Unlike a light fixture box, a ceiling fan box must always be supported by a joist, and it's easier to install one before the ceiling drywall has been installed. A new-work box, which you install during new construction, has a support bracket that screws to a pair of adjacent joists. Install the hanger bracket, sometimes called the mounting bracket, onto the box using screws and lock washers. Even if you aren’t supplied with any lock washers, get some, and use them. They’ll prevent your fan’s vibration from loosening the screws over time.

There were two screws that were originally "parked" in the box to secure the fan bracket to the "ears" and those screws have been removed and lost. Contact the mfgr and get some new screws, if you want the exact type originally supplied.

Most building codes require ceiling fans to be mounted on special fan-rated boxes made of metal or strong plastic with deep-threaded holes for the mounting screws. The box must be mounted firmly by attaching it directly to a framing member or using a fan-rated brace. Junction boxes like that one are 8-32. Ground screws are 10-32. Also, you could buy a ceiling hugger style fan instead of a stem mounted one, and fasten it directly to the ceiling with toggle bolts or similar fasteners, instead of just .What size screws fit in ceiling fan junction box? The most frequent type of screw used in electric boxes is the 6-32 flathead screw. For ceiling fan junction boxes, however, 8-32 or 10-32 screws are recommended for securing the connection . Installing a ceiling fan junction box is a crucial step in enhancing the ventilation and aesthetics of your living space. This guide will provide you with a comprehensive understanding of the process, empowering you to tackle this electrical task with confidence.

Feed the existing wire through the cable clamp in the top of the new metal ceiling fan junction box, slip the box over the saddle screws, and tighten the nuts to clamp the box to the shaft with a nut driver or a deep-well socket. Connecting a ceiling fan to a junction box is a manageable task that can be completed with the right tools and safety precautions. By following these step-by-step instructions and addressing any troubleshooting issues, you can enjoy the comfort and style of . In this comprehensive guide, we will provide you with a detailed step-by-step tutorial on how to install a ceiling fan junction box, ensuring a safe and secure installation. Connect the ground wire from the ceiling fan to the green or bare copper wire in the junction box. Unlike a light fixture box, a ceiling fan box must always be supported by a joist, and it's easier to install one before the ceiling drywall has been installed. A new-work box, which you install during new construction, has a support bracket that screws to a pair of adjacent joists.

sheet metal melbourne

installing junction box in ceiling

installing ceiling outlet box

Sheet metal has many applications in our daily lives, and the importance of this versatile material is often overlooked. Sheet metal material comes in a variety of thicknesses and finishes and is most commonly used in the construction and automotive industries.

ceiling fan screws for junction box installation|installing junction box in ceiling