cnc machine tool components $25K+ $2.19

0 · structure of cnc machine tools

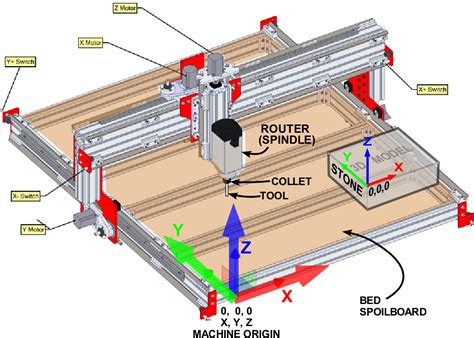

1 · schematic diagram of cnc machine

2 · parts made by cnc machine

3 · main parts of cnc machine

4 · main components of cnc machine

5 · cnc machine parts list pdf

6 · cnc machine components list

7 · block diagram of cnc machine

Junction Boxes are found in various electrical applications including enclosing wiring junctions as well as terminating lengths of cable using the adaptable junction box in conjunction with Armoured Cable Glands.

structure of cnc machine tools

The key components of a CNC machine include: 1. The Input Device. The input device of a CNC machine is responsible for loading CNC .

schematic diagram of cnc machine

In this article, we will explore the main parts of a CNC machine and explain the CNC block diagram in simple terms. 7 Key Components of a CNC Machine 1. Machine Control Unit .K+

Struggling to source CNC parts? Explore THECNCSOURCE.COM for easy access to top brands like Renishaw, Blum, Heidenhain, Acu-Rite, Zebra Skimmers and more.

Parts and Accessories. Order best-in-class machine parts and accessories that maintain and enhance your CNC machining equipment for improved accuracy, productivity, and ROI. .CNC machines perform incredible tasks that efficiently produce intricate components, surpassing traditional machining methods in both precision and cost-effectiveness. In this article, we’ll take a high-level look at CNC machine .

parts made by cnc machine

main parts of cnc machine

domestic electric meter box

Different parts of the CNC machine, such as spindles or tool changers, can quickly create parts from raw materials. The machine follows orders from a computerized system that directs the machine tools to perform .

SYIL meticulously designs the basic components, including the controller, servo motors, spindle, and tool changer, to ensure optimal performance and reliability in their CNC machines. In the next section, we will explore the essential parts of .

Order parts and accessories for all types of CNC machines. Cutting tools, workholders, toolholders, measurement and calibration devices, and more.Struggling to source CNC parts? Explore THECNCSOURCE.COM for easy access to top brands like Renishaw, Blum, Heidenhain, Acu-Rite, Zebra Skimmers and more. . Shop Machine Tool Shanks Shop Machine Specific .

CNC machines are modern subtractive manufacturing equipment, which automatically control the tool path and movement for material removal. You can find different types of CNC machines in industrial factories and the CNC Machine Shop, each with specific manufacturing purposes.However, all of them are used to craft the blank work material into the . Parts of CNC Machine + Function – Some significant components and elements that contribute to the machine’s efficacy are present in machine tools with CNC systems. Before utilizing any CNC machine, one must be .

As the representative energy-consuming equipment in the manufacturing industry, machine tools consume lots of energy during the nonmachining period, which leads to low energy efficiency. The existing strategies do not consider the startup sequence among components, which causes the control parameters to fail to run during the practical startup process, and this .A CNC machine that operates on wood CNC machines typically use some kind of coolant, typically a water-miscible oil, to keep the tool and parts from getting hot. A CNC metal lathe with the door open.. In machining, numerical control, also called computer numerical control (CNC), [1] is the automated control of tools by means of a computer. [2] It is used to operate tools such . 3. CNC (Computer Numeric Control) Computer Numeric Control (CNC) is the automation of machine tools that are operated by precisely programmed commands encoded on a storage medium (computer command module, usually located on the device) as opposed to controlled manually by hand wheels or levers, or mechanically automated by cams alone. In .

Section 1: Understanding CNC Machine Tool Components (200 words) Brief introduction to CNC machines and their components . Explanation of the three main components: machine, controller, and tooling . Overview of the role of each component in the CNC machining process . Section 2: Common CNC Machine Tool Repair Issues (300 words)CNC machining is a revolutionary technology. With its a great many advantages, a range of diverse CNC cutting tools is one of them. These advanced and versatile machines offer different CNC machine tools for various operations, from milling to turning, drilling, or electrical discharge.. A cutting tool is an instrument used to cut, shape, and remove CNC Machining material from a .When the CNC system was turned on, all its components were loaded, there were no critical errors prohibiting the operation of the machine tool (lack of power supply, pressure in the pneumatic and hydraulic lines, etc.), the system was ready for operation, namely it was ready to monitor machine tool health.

We specialize in supporting CNC Machine Tool spare parts. Spare parts requirements as with Bearings, Spindles, Ballscrew, Belts, Motors, Drives, Board. Welcome to The Buckman Group, Inc. Machine Tool Spare Parts. Free Ground Shipping on all orders Over 0.00 Veteran Owned and Operated Business . 734.277.4751 Machine Tool Spare Parts. Home; An ATC can either be mounted on the column or separately from the machine and the G-code from the CNC program activates the CNC tool changer to automatically replace the tool for further machining. However, CNC tool changers or ATCs can be expensive and are only suitable for industrial applications where high productivity is of utmost importance. The development of CNC machine tools started in the United States. In 1948, Parsons Co. had a preliminary idea to develop a CNC machine tool while working on a project to create a machine tool for processing the inspection template for helicopter blade profiles. The following year, with support from the United States Air Force Logistics Department, Parsons .

Features of CNC Machines • The tool or material moves. • Tools can operate in 1-5 axes. • Larger machines have a machine control unit (MCU) which manages operations. . in the automotive industry for producing components of Automotive industries.To know more in detail about automotive CNC machines components visit Saini Flange. 108 views .

Minimizing downtime is essential for productivity. At CNC Replacement Parts, we prioritize fast shipping to ensure quick delivery of parts. Our pre-wired, plumbed components, DIY repair kits, and tutorial videos empower you to perform timely repairs, keeping your machines running smoothly and efficiently.

Common types of CNC machines include; CNC lathe machines, CNC milling machines, CNC routers, 3D printers, and Laser and Plasma Cutters. In this article, I’ll focus on the basics of CNC milling machines. Keep reading .Millennium Machine & Tool is a CNC machined components manufacturer that has been hyper-serving high-precision industries like aerospace, agriculture, recreation, transportation, and the US military for more than 25 years.. Our full .

The rapid movement speed of the moving parts of the CNC machine tool shortens positioning and non-cutting time. CNC machine tools move according to coordinates, saving auxiliary operations such as line drawing and . CNC machine tools: These are devices or tools that enhance the performance, convenience, and safety of your CNC machine.They can help you with measuring, cutting, engraving, sanding, and more. Types of tools: There are different types of tools for different CNC machines and purposes.Some of the most common and useful tools are bits, end mills, face .The saddle is an integral part of a CNC machine that enables horizontal movement along the X-axis. It works with the column to provide stability and rigidity while allowing precise tool positioning during machining operations. The saddle is usually equipped with precision linear guides or ball screws to ensure smooth motion along the X-axis.

CNC machines are machine tools that cut or move material as programmed on the controller, as described above. The type of cutting can vary from plasma cutting to laser cutting, milling, routing, and lathes. . He or she then runs sample pieces and measures them with quality assurance tools to verify that the CNC machine is making parts .First, CNC milling machines use rotary cutting tools to remove material from a workpiece and make it into a shape or form that the user wants. These CNC machines help cut, shape, and drill different kinds of materials. . axis, and control panel are common parts of this CNC machine. CNC Plasma Cutters: CNC plasma cutters are amazing when . CNC machine tools and propose effective optimization methods to meet the manufacturing industry's demand for higher precision and performance. 2. Performance Analysis of Existing High-End CNC Machine Tools 2.1. Importance of High-End CNC Machine Tools High-end CNC machine tools hold exceptional imp. ortance in the field of modern manufacturing.Established in 1985, Billor McDowell provides repairs on all makes and models of CNC machine tools. We are recognized throughout the Southern United States for responsive service by professional technicians that have an exceptional ability to diagnose and repair any problem that you may have with your machine tool.

With an emphasis on preventive maintenance to keep your machine tool running, our CARE Kits help ensure your Okuma machine tool's mechanical, electrical, lubrication, airflow, and coolant systems will continue to operate in “like-new” condition. After the preparation, the CNC then controls the axis of the motion, spindle function or tool function on the machine, following the part program stored in the memory. Machine Tool – There are different types of machine tools a CNC controls but what they all have in common is a slide table and a spindle to control the position and speed. The moving components of machine tools consume a large amount of energy in the operating stage. Structure optimization of moving components is a key strategy for energy saving in machine tools design. Traditionally, structural optimization of machine tools is carried out for reducing energy consumption or improving static and dynamic performance.The machine tool is the part of the CNC machine that actually performs the cutting, drilling, or milling operations. . Understanding the parts of a CNC machine and their functions, as illustrated in the CNC block diagram, is fundamental for anyone working with or learning about CNC technology. Each component plays a critical role in ensuring .

main components of cnc machine

cnc machine parts list pdf

In most cases, CNC machines use different types of cutting tools depending on the nature of the job at hand. These can include drills, end mills, and routers, among others. The spindle is another critical component that .

cnc machine tool components|schematic diagram of cnc machine