design for manufacturability for cnc machining Designing for manufacturability accelerates the CNC machining process, reduces operating costs, elevates energy efficiency, and helps product teams create clean, functional parts. Refer to . Source over 17411 cnc machined parts for sale from manufacturers with factory direct prices, high quality & fast shipping.CNC Shop is One-Stop Shop of Premium parts for CNC Routers & WaterJet Machines. Shop Online for all AXYZ routers & WARDJet parts. Vast collection of Router parts including Solid .

0 · manufacturing design for manufacturability

1 · manufacturing cnc design checklist

2 · manufacturability cnc checklist

3 · dfm cnc

4 · design for manufacturability training

5 · design for manufacturability

6 · cnc machining design for manufacturing

7 · cnc design for manufacturability

Look through the wide range of wholesale custom milling turning cnc parts listings on Alibaba.com to find the right provider for your machining needs. All kinds of machining services are covered here.Rally offers unparalleled precision and reliability as a trusted supplier of high quality turned parts. We specialize in making parts that strictly adhere to specified shape, size and material .

CNC (Computer Numerical Control) machining is a widely used precision machining process. Here, we share some design guidelines and .Designing for manufacturability accelerates the CNC machining process, reduces operating costs, elevates energy efficiency, and helps product teams create clean, functional parts. Refer to . Designing for manufacturability accelerates the CNC machining process, reduces operating costs, elevates energy efficiency, and helps product teams create clean, functional parts. Refer to this short checklist often to make sure your designs are on the right track, but an experienced manufacturing partner like SyBridge can offer more nuanced .CNC (Computer Numerical Control) machining is a widely used precision machining process. Here, we share some design guidelines and best practices specific to CNC machining. Feature Sizes: Consider the capabilities of the CNC machine and tooling when determining feature sizes.

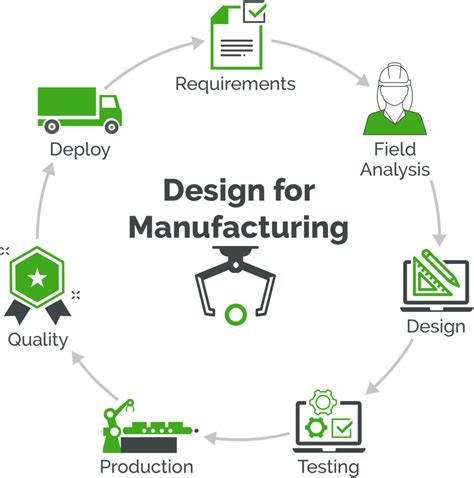

Designing for manufacturability accelerates the CNC machining process, reduces operating costs, elevates energy efficiency, and helps product teams create clean, functional parts. Refer to this short checklist often to make sure your designs are on the right track, but an experiencedEvery manufacturing process—be it injection molding, CNC machining, or additive manufacturing—has its own set of guidelines for optimal design. For example, consider factors like wall thickness, draft angles, and gate locations if .Get in-depth design advice to optimize your plastic and metal parts for CNC machining. Designing with machining in mind can accelerate production time and reduce production costs. There are many design considerations involved when creating CNC machined plastic and metal parts. Design for Manufacturability (DFM) is more than just a buzzword; it’s a systematic approach that bridges innovative concepts with practical manufacturability in CNC machining. Here’s a step-by-step guide on how to seamlessly integrate DFM principles into CNC designs:

In this article, we’ll be taking a deep dive into CNC machining DFM. We’ll start by building an understanding of how modern CNC milling machines work and what capabilities are typical. Then we’ll dive into the machining process itself by focusing on tools, setups and machining strategies. Thus, it is essential to adhere to the basic rule of thumb and design guidelines that apply to CNC machining of standard features in CNC machined parts. This guide explores the basics of CNC machining design and best practices for different CNC operations. Read on to . Automatic manufacturability assessment is a competitive edge for business that want to optimize their production. For instance, the DFMPro software makes use of a rule-based checker system.

The foundation for success lies in designing parts that are inherently well-suited for the machining process. In this article, we’ll delve into the key guidelines and design principles for creating parts that optimize manufacturability through CNC machining. Designing for manufacturability accelerates the CNC machining process, reduces operating costs, elevates energy efficiency, and helps product teams create clean, functional parts. Refer to this short checklist often to make sure your designs are on the right track, but an experienced manufacturing partner like SyBridge can offer more nuanced .CNC (Computer Numerical Control) machining is a widely used precision machining process. Here, we share some design guidelines and best practices specific to CNC machining. Feature Sizes: Consider the capabilities of the CNC machine and tooling when determining feature sizes.

Designing for manufacturability accelerates the CNC machining process, reduces operating costs, elevates energy efficiency, and helps product teams create clean, functional parts. Refer to this short checklist often to make sure your designs are on the right track, but an experiencedEvery manufacturing process—be it injection molding, CNC machining, or additive manufacturing—has its own set of guidelines for optimal design. For example, consider factors like wall thickness, draft angles, and gate locations if .Get in-depth design advice to optimize your plastic and metal parts for CNC machining. Designing with machining in mind can accelerate production time and reduce production costs. There are many design considerations involved when creating CNC machined plastic and metal parts. Design for Manufacturability (DFM) is more than just a buzzword; it’s a systematic approach that bridges innovative concepts with practical manufacturability in CNC machining. Here’s a step-by-step guide on how to seamlessly integrate DFM principles into CNC designs:

manufacturing design for manufacturability

In this article, we’ll be taking a deep dive into CNC machining DFM. We’ll start by building an understanding of how modern CNC milling machines work and what capabilities are typical. Then we’ll dive into the machining process itself by focusing on tools, setups and machining strategies. Thus, it is essential to adhere to the basic rule of thumb and design guidelines that apply to CNC machining of standard features in CNC machined parts. This guide explores the basics of CNC machining design and best practices for different CNC operations. Read on to . Automatic manufacturability assessment is a competitive edge for business that want to optimize their production. For instance, the DFMPro software makes use of a rule-based checker system.

metal fabrication regina

manufacturing cnc design checklist

Discover our extensive range of affordable aftermarket CNC replacement parts, designed to keep your machines operating at peak performance. Our high-quality 100% Free Shipping in USA!

design for manufacturability for cnc machining|manufacturing cnc design checklist