calculate cnc machining time reduction Calculating cycle time involves solving mathematical relations for operations such as milling, turning, drilling, and many more. This article will provide a brief overview of cycle .

$36.99

0 · production cycle time cnc

1 · how to calculate cnc time

2 · cnc time calibration

3 · cnc milling time calculator

4 · cnc machining time formula

5 · cnc machining time

6 · cnc machining cycle time calculator

7 · cnc cycle time calculator excel

Sigma's weatherproof one-gang boxes provide a junction for conduits and can house a single wired device such as a receptacle or switch. They can also be used to mount lampholders and lighting systems in outdoor applications.

Calculating CNC Machining Time. The basic CNC machining formula is length or distance divided by speed or rate. This formula makes it possible to calculate machining time by using one of its derivatives: . To calculate the CNC machining time accurately, you need to follow a structured process that considers all relevant factors of the machining operation. Here’s how you can . Calculating cycle time involves solving mathematical relations for operations such as milling, turning, drilling, etc. This article will briefly overview .Well with Carveco Maker, you’re able to accurately calculate how long it’s going to take to machine your design! In this addition to our Tips and Tricks, we’ll show you how to easily calibrate your software to give you those accurate calculations!

Understanding how to calculate CNC machining time is essential for optimizing production processes, estimating costs, and ensuring on-time delivery of parts to clients. In this comprehensive guide, we will delve deep into the world of CNC . Calculating cycle time involves solving mathematical relations for operations such as milling, turning, drilling, and many more. This article will provide a brief overview of cycle .

Follow us to figure out how to calculate CNC machining time for the milling process with a detailed example, then understand the turning/milling machining time calculation formula better. When calculating or estimating the CNC machining cycle time for the turning process, the formula is also based on. T=L/feed*N. The L or length= (tool approach+job length+tool over travels)*No. Of passes. The N refers to .

production cycle time cnc

Calculating CNC Machining Time. The basic CNC machining formula is length or distance divided by speed or rate. This formula makes it possible to calculate machining time by using one of its derivatives: Revolutions Per Minute = 1,000 x Cutting Speed (mm per minute) / π x Diameter of Rod (mm) To calculate the CNC machining time accurately, you need to follow a structured process that considers all relevant factors of the machining operation. Here’s how you can approach it: Determine the Total Length of Cut: This is the cumulative distance that the cutting tool will travel while machining the part. It includes all passes and is . Calculating cycle time involves solving mathematical relations for operations such as milling, turning, drilling, etc. This article will briefly overview cycle time computation for various CNC machining operations, the impacts of production cycle time & its reduction approaches. 2.1 1. CNC Milling. 2.2 2. CNC Turning. 2.3 3. CNC Drilling.

Well with Carveco Maker, you’re able to accurately calculate how long it’s going to take to machine your design! In this addition to our Tips and Tricks, we’ll show you how to easily calibrate your software to give you those accurate calculations!

Understanding how to calculate CNC machining time is essential for optimizing production processes, estimating costs, and ensuring on-time delivery of parts to clients. In this comprehensive guide, we will delve deep into the world of CNC machining cycle time calculation. Calculating cycle time involves solving mathematical relations for operations such as milling, turning, drilling, and many more. This article will provide a brief overview of cycle time computation for various CNC machining operations, the impacts of production cycle time & its reduction approaches. Calculation of Production Cycle Time. Follow us to figure out how to calculate CNC machining time for the milling process with a detailed example, then understand the turning/milling machining time calculation formula better. When calculating or estimating the CNC machining cycle time for the turning process, the formula is also based on. T=L/feed*N. The L or length= (tool approach+job length+tool over travels)*No. Of passes. The N refers to average RPM, which is equal to 1000*cutting speed/π*average diameter.

Welcome to our comprehensive guide on calculating cycle time in CNC machines. Understanding cycle time is crucial for optimizing production efficiency and ensuring accurate cost estimation in the manufacturing industry. To reduce idle time, it is essential to thoroughly understand the series of operations. Repeatedly perform dry runs, observe the idle time, cutting time, and machine operations, and identify opportunities to shorten the time by checking . Calculating CNC Machining Time. The basic CNC machining formula is length or distance divided by speed or rate. This formula makes it possible to calculate machining time by using one of its derivatives: Revolutions Per Minute = 1,000 x Cutting Speed (mm per minute) / π x Diameter of Rod (mm)

To calculate the CNC machining time accurately, you need to follow a structured process that considers all relevant factors of the machining operation. Here’s how you can approach it: Determine the Total Length of Cut: This is the cumulative distance that the cutting tool will travel while machining the part. It includes all passes and is . Calculating cycle time involves solving mathematical relations for operations such as milling, turning, drilling, etc. This article will briefly overview cycle time computation for various CNC machining operations, the impacts of production cycle time & its reduction approaches. 2.1 1. CNC Milling. 2.2 2. CNC Turning. 2.3 3. CNC Drilling.Well with Carveco Maker, you’re able to accurately calculate how long it’s going to take to machine your design! In this addition to our Tips and Tricks, we’ll show you how to easily calibrate your software to give you those accurate calculations!

Understanding how to calculate CNC machining time is essential for optimizing production processes, estimating costs, and ensuring on-time delivery of parts to clients. In this comprehensive guide, we will delve deep into the world of CNC machining cycle time calculation.

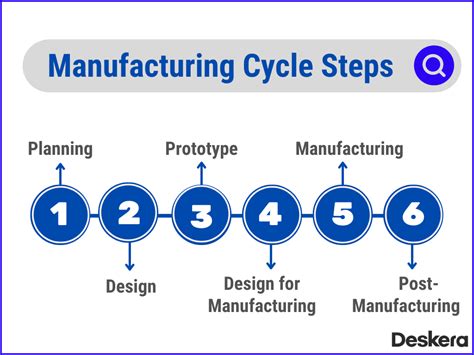

Calculating cycle time involves solving mathematical relations for operations such as milling, turning, drilling, and many more. This article will provide a brief overview of cycle time computation for various CNC machining operations, the impacts of production cycle time & its reduction approaches. Calculation of Production Cycle Time.

Follow us to figure out how to calculate CNC machining time for the milling process with a detailed example, then understand the turning/milling machining time calculation formula better. When calculating or estimating the CNC machining cycle time for the turning process, the formula is also based on. T=L/feed*N. The L or length= (tool approach+job length+tool over travels)*No. Of passes. The N refers to average RPM, which is equal to 1000*cutting speed/π*average diameter.Welcome to our comprehensive guide on calculating cycle time in CNC machines. Understanding cycle time is crucial for optimizing production efficiency and ensuring accurate cost estimation in the manufacturing industry.

how to calculate cnc time

junction box with lugs

cnc time calibration

This manual provides information for identification of replacement parts for the Ovation 2 HS Ultra High Capacity Fuel & DEF dispenser series. This manual is not provided as a guide to

calculate cnc machining time reduction|production cycle time cnc