cnc machine inspection report format The customers I have who require a specific inspection form and/or "1st Article Inspection Sheet" have actually emailed a .pdf of the ones they use and allow me to add my . The shingles used for a Colonial style roof tend to be natural, but they don't have to be; possible materials include wood, slate, asphalt, and even synthetic. Popular Colonial Style Roof Shingles 1. Wood Shakes & Wood Shingles. By far, wood shakes and wood shingles are the most common roofing material for colonial style roofs.Architectural metal fabric is best defined as an arrangement of high-tensile, 300 series stainless steel wires woven together, forming decorative wire mesh panels.Parameters, such as the mesh pattern, percentage of open area, panel size, and wire diameter, are fully customizable, making metal fabric . See more

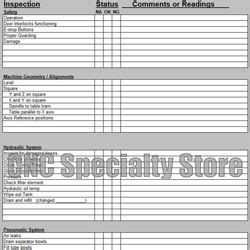

0 · vertical cnc preventive maintenance form

1 · vertical cnc pm form

2 · vertical cnc inspection form

3 · printable inspection report template

4 · excel inspection report

Metallic fabrics are a surefire way to make a statement, whether in bold evening wear or as an accent in an everyday look. But how do you find the perfect metallic fabric, and what are the different types? Learn all this and more in our Zelouf guide to metallic fabric.

Starting a PM program? Here is a Vertical CNC Preventive Maintenance & Inspection Form. More preventive maintenance forms available for lathes and HMC horizontal machining centers from . Many of our inspection options will provide you with a Xometry dimensional inspection report along with a correlated ballooned print. We have provided examples below of what to expect when selecting these options.PDF Template, Machine inspection report to ensure all manufacturing tasks have been completed

ONE:General Rules for Inspection Report of CNC machined parts factory. 1. Inspectors need to have more professional knowledge and practical work experience, and also need to meet the requirements of advanced . The customers I have who require a specific inspection form and/or "1st Article Inspection Sheet" have actually emailed a .pdf of the ones they use and allow me to add my .Read Level at Front, Middle, Back for both X & Y Axis Directions. Federal Level: Record the values. Bubble Level: Draw in the bubble position. 2. PARALLELISM OF TABLE TO X - Y .

It lists 13 check points to inspect visually and manually on a daily basis, including ensuring proper oil, coolant, and hydraulic fluid levels; that machine guards and doors are securely in place; checking for abnormal sounds; inspecting for . Quality testing and inspection in CNC machining applications represent a critical phase, ensuring every machined component meets the high standards of precision and excellence. This article dives into the intricate world .

Ensure the optimal performance of your CNC machine with this comprehensive daily maintenance checklist: Mechanical. Ensure cleanliness around the chuck or spindle and the machine bed. Verify the security of all covers or guards. Clean . The neatest inspection report I've seen is just bubbles. There is a grid of bubbles, the range between max and min tolerance is the Y (vertical) axis, the number of parts is the X (cross) axis. You fill in the bubble for each part.Starting a PM program? Here is a Vertical CNC Preventive Maintenance & Inspection Form. More preventive maintenance forms available for lathes and HMC horizontal machining centers from the CNC Specialty Store.

vertical cnc preventive maintenance form

Many of our inspection options will provide you with a Xometry dimensional inspection report along with a correlated ballooned print. We have provided examples below of what to expect when selecting these options.PDF Template, Machine inspection report to ensure all manufacturing tasks have been completed ONE:General Rules for Inspection Report of CNC machined parts factory. 1. Inspectors need to have more professional knowledge and practical work experience, and also need to meet the requirements of advanced machined parts for inspection work; 2. The customers I have who require a specific inspection form and/or "1st Article Inspection Sheet" have actually emailed a .pdf of the ones they use and allow me to add my own header so their inspection dept. has all the crucial requirements exactly as they have set up according to their inspection requirements as they know and work with everyday.

Read Level at Front, Middle, Back for both X & Y Axis Directions. Federal Level: Record the values. Bubble Level: Draw in the bubble position. 2. PARALLELISM OF TABLE TO X - Y MOTION. 3. INSPECT SQUARENESS OF X-AXIS TO Y-AXIS. ALIGN PRECISION SQUARE WITH X-AXIS INDICATE ALONG Y-AXIS. 4. T-SLOT STRAIGHTNESS.It lists 13 check points to inspect visually and manually on a daily basis, including ensuring proper oil, coolant, and hydraulic fluid levels; that machine guards and doors are securely in place; checking for abnormal sounds; inspecting for leaks; ensuring cutting tools and holders are tight; and keeping the machine clean and lubricated.

Quality testing and inspection in CNC machining applications represent a critical phase, ensuring every machined component meets the high standards of precision and excellence. This article dives into the intricate world of quality testing and inspection, elucidating its significance, methodologies, and the innovations shaping its future.

Ensure the optimal performance of your CNC machine with this comprehensive daily maintenance checklist: Mechanical. Ensure cleanliness around the chuck or spindle and the machine bed. Verify the security of all covers or guards. Clean slide rails, such as doors or covers, to maintain smooth movement. Electrical. The neatest inspection report I've seen is just bubbles. There is a grid of bubbles, the range between max and min tolerance is the Y (vertical) axis, the number of parts is the X (cross) axis. You fill in the bubble for each part.Starting a PM program? Here is a Vertical CNC Preventive Maintenance & Inspection Form. More preventive maintenance forms available for lathes and HMC horizontal machining centers from the CNC Specialty Store.

Many of our inspection options will provide you with a Xometry dimensional inspection report along with a correlated ballooned print. We have provided examples below of what to expect when selecting these options.PDF Template, Machine inspection report to ensure all manufacturing tasks have been completed

ONE:General Rules for Inspection Report of CNC machined parts factory. 1. Inspectors need to have more professional knowledge and practical work experience, and also need to meet the requirements of advanced machined parts for inspection work; 2. The customers I have who require a specific inspection form and/or "1st Article Inspection Sheet" have actually emailed a .pdf of the ones they use and allow me to add my own header so their inspection dept. has all the crucial requirements exactly as they have set up according to their inspection requirements as they know and work with everyday.

vertical cnc pm form

Read Level at Front, Middle, Back for both X & Y Axis Directions. Federal Level: Record the values. Bubble Level: Draw in the bubble position. 2. PARALLELISM OF TABLE TO X - Y MOTION. 3. INSPECT SQUARENESS OF X-AXIS TO Y-AXIS. ALIGN PRECISION SQUARE WITH X-AXIS INDICATE ALONG Y-AXIS. 4. T-SLOT STRAIGHTNESS.It lists 13 check points to inspect visually and manually on a daily basis, including ensuring proper oil, coolant, and hydraulic fluid levels; that machine guards and doors are securely in place; checking for abnormal sounds; inspecting for leaks; ensuring cutting tools and holders are tight; and keeping the machine clean and lubricated. Quality testing and inspection in CNC machining applications represent a critical phase, ensuring every machined component meets the high standards of precision and excellence. This article dives into the intricate world of quality testing and inspection, elucidating its significance, methodologies, and the innovations shaping its future.

direct industry electrical enclosure metric

discount metal brackets

Galvanizing, or galvanization, is a manufacturing process where a coating of zinc is applied to steel or iron to offer protection and prevent rusting. There are several galvanizing processes available, but the most commonly offered and used method is called hot-dip galvanizing.

cnc machine inspection report format|vertical cnc preventive maintenance form