180 degree hem on sheet metal In a flat or closed hem, the part of the edge that bends sits completely flush over the rest of the metal sheet. The angle between the returning flange and the sheet metal is 180 degrees. The inside radius is zero and thus, . $50.30

0 · sheet metal roller hemming

1 · sheet metal hems types

2 · sheet metal hemming techniques

3 · sheet metal hemming procedure

4 · sheet metal hemming machine

5 · sheet metal heming angle

6 · sheet metal hem forms

7 · open hem sheet metal

Our wide range of metal fabrication services mean we can make virtually anything in metal that you want and in any quantity. Areas we cover is Cambridgeshire, Peterborough and surrounding areas. Tel: 01945 464637.

In a flat or closed hem, the part of the edge that bends sits completely flush over the rest of the metal sheet. The angle between the returning flange and the sheet metal is 180 degrees. The inside radius is zero and thus, .

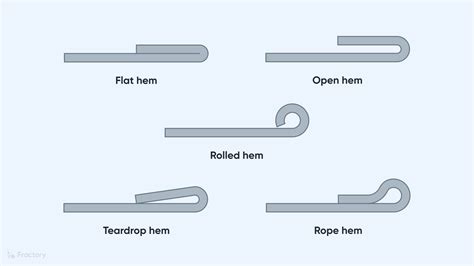

The four most common types of sheet metal hems used by Approved Sheet Metal are closed hem, teardrop hem, open hem, and rolled .Sheet metal hem radius, there is only one 180-degree bend in a hem. Some hems are closed, which means that the inside bend radius is zero. The hem’s cross-section resembles a U if its radius is bigger than zero. The hem has one curve rather than . In a flat or closed hem, the part of the edge that bends sits completely flush over the rest of the metal sheet. The angle between the returning flange and the sheet metal is 180 degrees. The inside radius is zero and thus, there is no . The four most common types of sheet metal hems used by Approved Sheet Metal are closed hem, teardrop hem, open hem, and rolled hem. What are the material limitations for closed hems? Closed hems work best with material thicknesses of .040"-.125".

Closed hem, the most popular type, is also known as crushed hem. In this case, the returning flange is at 180 degrees to the sheet metal, with no gap in between. The flat profile is easy to make – fold the sheet metal edge 145 degrees first and then flatten it with a press.

The main difference is that sheet metal hemming is a 180-degree fold, and some hems are sealed, meaning there is no inside radius. If the radius is more significant than zero, then the cross-section of a hem can be described as a figure resembling the letter U. The main aim of sheet metal hems is to make a safe, smooth edge on metal components. It reinforces the edge, increases stiffness and allows assembly of multiple parts. Heming also increases visual appeal by removing sharp edges and giving a .

12 v distribution box turn on with key in ignitio

sheet metal roller hemming

Working on the Hem. A hem is a single, 180-degree bend. Some hems are closed—basically a zero inside bend radius. If the hem has a radius greater than zero, it resembles a U in cross section. Unlike the U-channels discussed in Part III, the hem has only one bend instead of two. If no flat section to the hem is evident, it is simply an edge bead.The open hem type allows you to fold the edge of the sheet metal to a 180-degree angle while leaving some space between the hem part and the primary sheet metal area. You can use the open hem space for various purposes, such as to ease the assembly process.A hem bend is an edge of sheet metal that is bent 180 degrees and flattened on top of itself.As we mentioned above, sheet metal hemming is a process of folding the edge of a single metal sheet back onto itself to create a clean, finished edge. This is typically done by bending the metal over a die or roller, resulting in a 180-degree fold or a tighter, more acute angle.

Sheet metal hem radius, there is only one 180-degree bend in a hem. Some hems are closed, which means that the inside bend radius is zero. The hem’s cross-section resembles a U if its radius is bigger than zero. The hem has one curve rather than . In a flat or closed hem, the part of the edge that bends sits completely flush over the rest of the metal sheet. The angle between the returning flange and the sheet metal is 180 degrees. The inside radius is zero and thus, there is no .

The four most common types of sheet metal hems used by Approved Sheet Metal are closed hem, teardrop hem, open hem, and rolled hem. What are the material limitations for closed hems? Closed hems work best with material thicknesses of .040"-.125". Closed hem, the most popular type, is also known as crushed hem. In this case, the returning flange is at 180 degrees to the sheet metal, with no gap in between. The flat profile is easy to make – fold the sheet metal edge 145 degrees first and then flatten it with a press.

The main difference is that sheet metal hemming is a 180-degree fold, and some hems are sealed, meaning there is no inside radius. If the radius is more significant than zero, then the cross-section of a hem can be described as a figure resembling the letter U. The main aim of sheet metal hems is to make a safe, smooth edge on metal components. It reinforces the edge, increases stiffness and allows assembly of multiple parts. Heming also increases visual appeal by removing sharp edges and giving a .

Working on the Hem. A hem is a single, 180-degree bend. Some hems are closed—basically a zero inside bend radius. If the hem has a radius greater than zero, it resembles a U in cross section. Unlike the U-channels discussed in Part III, the hem has only one bend instead of two. If no flat section to the hem is evident, it is simply an edge bead.The open hem type allows you to fold the edge of the sheet metal to a 180-degree angle while leaving some space between the hem part and the primary sheet metal area. You can use the open hem space for various purposes, such as to ease the assembly process.A hem bend is an edge of sheet metal that is bent 180 degrees and flattened on top of itself.

12 sheet metal rolls

sheet metal hems types

12 hole distribution box

sheet metal hemming techniques

Air Conditioning Contractors in Lakeland, FL. See BBB rating, reviews, complaints, & more.

180 degree hem on sheet metal|sheet metal hemming procedure