fabricated metal vs primary metal Choosing a metal fabrication method suited to a given project depends on the designed part’s geometry, the product’s intended purpose, and the materials used in crafting it. Common metal fabrication processes are as .

Use a metal electrical box when metal-sheathed cable (also called armored BX cable) or metal conduit runs in or out of the box. Metal cable and conduit depend on the contact from its metal sheathing to the metal box to complete grounding.

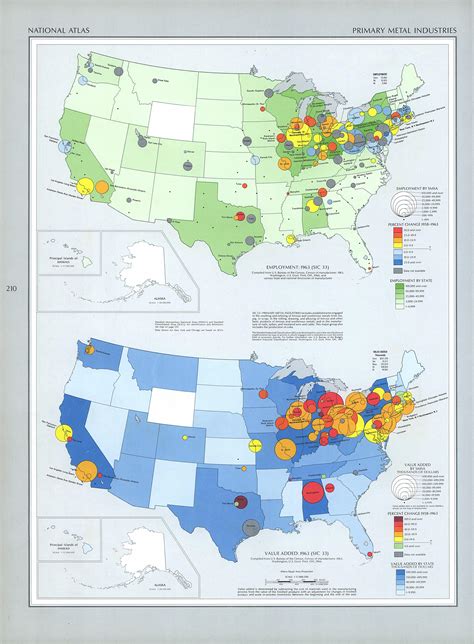

0 · us primary metals industry

1 · us manufactured metals industry

2 · primary metals manufacturing industry

3 · primary metals industry trends

4 · manufactured metal manufacturing industry

5 · fabricated metal industries

Use a metal electrical box when metal-sheathed cable (also called armored BX cable) or metal conduit runs in or out of the box. Metal cable and conduit depend on the contact from its metal sheathing to the metal box to complete grounding.

us primary metals industry

metal junction box vs plastic

Fabricated metal is metal products or structures created by metal fabrication, including cutting, bending, and assembling. Fabrication of metal has three main phases, design, fabrication, and installation. Primary metals companies import more raw materials, 17% versus 11% for manufacturing in general. This difference follows from the fact that primary metals provide other industries with raw materials. Minority ownership .• The United States exported .7 billion of fabricated metal products in 2014, with metal valves alone accounting for 30 percent of total exports. • On the other hand, the United States .Process. Primary and secondary steelmaking processes differ somewhat. Primary structural steel is usually made with high-strength, low-alloy (HSLA) steel. The process is called the Basic .

By Dr. Chris Kuehl | December 13, 2023. Category: Fabrinomics. Primary metal industrial production is forecast to increase by 10.9% in 2023 (12.8% in the last report). This is a volatile sector and is being driven heavily .

Choosing a metal fabrication method suited to a given project depends on the designed part’s geometry, the product’s intended purpose, and the materials used in crafting it. Common metal fabrication processes are as . Steel manufacturing gives birth to raw steel on an industrial scale, while steel fabrication crafts this raw material into precision-engineered components tailored to specific needs. Technology has revolutionized both . Primary steelmaking uses a blower to force oxygen through molten iron, whereas secondary steelmaking is characterized by the use of an electric arc. The electric arc is able to heat up the scrap iron until it achieves a molten . Material Composition Differences. Manufacturing Process Variances. Primary Applications and Industries. Advantages and Disadvantages. Advantages of Structural Steel. .

Joining Metals: Welders focus on joining metals, often working with components that are pre-fabricated or prepared by metal fabricators. Quality Control: Ensuring the quality of welds is a primary responsibility. Welders inspect their work to .

Establishments primarily engaged in performing the following types of services on metals, for the trade: (1) enameling, lacquering, and varnishing metal products; (2) hot dip galvanizing of mill sheets, plates and bars, castings, and formed products fabricated of iron and steel; hot dip coating such items with aluminum, lead, or zinc; retinning cans and utensils; (3) engraving, chasing .Establishments primarily engaged in performing the following types of services on metals, for the trade: (1) enameling, lacquering, and varnishing metal products; (2) hot dip galvanizing of mill sheets, plates and bars, castings, and formed products fabricated of iron and steel; hot dip coating such items with aluminum, lead, or zinc; retinning cans and utensils; (3) engraving, chasing .Metal Fabrication Metal fabrication is the process of cutting, bending, and assembling metal components to create a structure or product. It involves a variety of processes, including welding, cutting, forming, and assembly. Metal fabrication is used to create a wide range of products, from small components to large structures. Browse All Tags

us manufactured metals industry

Graph and download economic data for Producer Price Index by Industry: Miscellaneous Fabricated Metal Product Manufacturing: Primary Products (PCU332999332999P) from Dec 2003 to Sep 2024 about fabrication, miscellaneous, primary, metals, manufacturing, PPI, industry, inflation, price index, indexes, price, and USA.K-State Pollution Prevention Institute’s P2 intern program. It focuses on metal manufacturing and fabricated metal product subsectors utilizing various processes that emit pollutants. These process include smelting and refining metals to make primary metal products such as sheets, rods, wires and castings. These primary metal products areAbout the Primary Metal Manufacturing subsector The primary metal manufacturing subsector is part of the manufacturing sector. Industries in the Primary Metal Manufacturing subsector smelt and/or refine ferrous and nonferrous metals from ore, pig or scrap, using electrometallurgical and other process metallurgical techniques. However, only half the percentage of primary metals companies are woman-owned as compared to manufacturing as a whole—1% versus 2%, respectively. Public ownership in the primary metals industry is relatively high, at 14% compared to 5% for all manufacturing. Primary metals manufacturers cluster in the Midwest at 38% and the South at 29%.

In the intricate realm of metalwork, mastering diverse techniques is paramount. Yet, many grapple with distinguishing between metal stamping and metal fabrication—two core methods. For industry aficionados and professionals alike, understanding this distinction is crucial for optimal outcomes. Metal stamping is the art of employing dies to morph flat metal.

Graph and download economic data for Producer Price Index by Industry: Primary Metal Manufacturing (PCU331331) from Dec 1984 to Sep 2024 about primary metals, primary, metals, manufacturing, PPI, industry, inflation, price index, indexes, price, and USA.Metal Worker VS. Metal Fabicator Sheet metal work and metal fabrication are two interconnected yet distinct professions within the metalworking industry. While both involve working with metal materials, there are significant differences in their roles, responsibilities, tools, and areas of expertise. This article explores the distinctions between a sheet metal worker and a metal .

The state’s primary metals manufacturing GDP rose by an inflation-adjusted 87 percent from 1997 through 2015, compared to 33 percent nationwide (Exhibit 2). Industries in Primary Metals Manufacturing. The subsector’s employment in Texas rose by a slight 2.1 percent from 2010 through 2016, led by gains nonferrous metal production. MIG (Metal Inert Gas) welding or Gas Metal Arc Welding (GMAW) is a process in which a welding gun feeds a wire electrode, which melts and serves as the filler material between steel parts. The welding gun also emits a shielding gas like Argon or CO2 to prevent contamination or oxidation from the surrounding air. Metals like aluminum, steel, and copper are commonly used in bending due to their ductility and malleability. . One of the primary advantages of forming is its flexibility in creating intricate shapes and designs. However, this complexity also presents challenges. Forming processes require careful design and engineering to ensure the final .Establishments primarily engaged in performing the following types of services on metals, for the trade: (1) enameling, lacquering, and varnishing metal products; (2) hot dip galvanizing of mill sheets, plates and bars, castings, and formed products fabricated of iron and steel; hot dip coating such items with aluminum, lead, or zinc; retinning cans and utensils; (3) engraving, chasing .

Investment Casting: In investment casting, also known as lost-wax casting, the process starts with creating a wax model that mimics the part you want to make.This wax model is then covered with a ceramic material, which hardens into a mold. Once the ceramic has set, the wax is melted away, leaving a hollow space in the shape of the part.Definition: Fabrication refers to the process of constructing products by manipulating raw materials, often involving cutting, bending, and assembling. While it can apply to various materials, in the context of this article, we focus .

The primary difference between steel fabrication vs metal fabrication lies in the material being used. Steel fabrication focuses exclusively on steel, while metal fabrication involves a variety of metals. This distinction impacts the fabrication process, tools required and the final product’s characteristics.The construction industry continues to evolve. Builders, architects, and developers are constantly seeking innovative and efficient methods to deliver projects on time, within budget, and with a high degree of quality. Pre-engineered metal buildings (PEBs) are emerging as a significant contender against traditional construction methods, offering a range of benefits that deliver quick, budget .5. Initial Costs. Steel building systems may have a higher initial cost compared to other building materials, including tubular systems. On average, you can expect to pay between and per square foot for your steel building base alone, but the actual range can go up to 0 per square foot.. These costs are dictated by the price of steel which can fluctuate based on .Introduction to the three 3 types of metal fabrication Metal fabrication is the backbone of many industries, from the cars we drive to the buildings we live and work in. At its core, metal fabrication is the process of creating metal structures by cutting, bending, and assembling. It’s a craft that requires precision, expertise, and. Continue reading Three Types of Metal Fabrication

The Cost of Metal Fabrication. Metal prices significantly shape fabrication trends. When participants were tasked with prioritizing challenges in fabricating metal parts, 45% identified material cost as their foremost concern. Following closely, material availability was noted by 42% of respondents. The primary objective of sheet metal fabrication is to produce metal parts in desired shapes and sizes. Depending on the project's requirements, the metal fabricator employs these techniques, ensuring that flat metal sheets—whether steel or aluminum—can be stretched, cut, bent, or assembled into a variety of complex shapes. .The North American fabricated metal products market is valued around USD 43 billion in the current year and is anticipated to register a CAGR of more than 4% during the forecast period. . the US metals and steel industry is facing increased competition from EU peers in its domestic market. This has limited domestic production's growth in 2022 .Nine Metal Fabrication and Finishing Source Categories 40 CFR Part63 Subpart XXXXXX EPA has new requirements to reduce air pollution of compounds of metals such as cadmium, chromium, lead, manganese and nickel from nine metal fabrication and finishing source categories. These compounds pose health risks to anyone who breathes

Metal Fabrication: Metal fabrication is constructing metal structures, components, or products from raw materials such as sheet metal, rods, or bars by cutting, shaping, and assembling them. It is a more specialized and personalized technique in which individual items are produced to specific designs or specifications. Metal Manufacturing:Establishments primarily engaged in performing the following types of services on metals, for the trade: (1) enameling, lacquering, and varnishing metal products; (2) hot dip galvanizing of mill sheets, plates and bars, castings, and formed products fabricated of iron and steel; hot dip coating such items with aluminum, lead, or zinc; retinning cans and utensils; (3) engraving, chasing .

$612.31

fabricated metal vs primary metal|primary metals manufacturing industry