sheet metal chassis processing technology A new generation of fluid pressure forming technology has been developed for the three typical structures of tubes, sheets, and shells, and hard-to-deform material components . A vintage box metal wood — often made from wood, metal and brass — can elevate any home. Find 382 options for an antique or vintage vintage box metal wood now, or shop our selection of 6 modern versions for a more contemporary example of this long-cherished piece.

0 · sheet metal manufacturing technology

1 · sheet metal manufacturing process

2 · sheet metal manufacturing companies

3 · sheet metal forming

4 · sheet forming process

$35.09

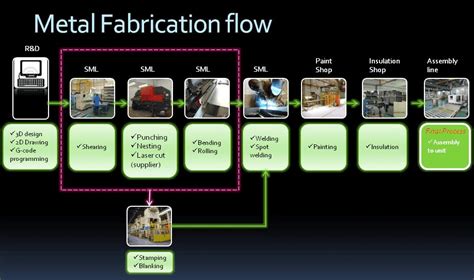

Using sheet metal chassis processing technology to make sheet metal chassis shell has many characteristics. Analyzing and utilizing these properties will often provide a more stable and safer environment for the . Discover the transformative technologies and methodologies in sheet metal manufacturing revolutionizing industrial production. Delve into precision techniques, advanced quality control methods, applications, and . Generally, the sheet metal fabrication methods of sheet metal chassis parts are fixed, consisting of cutting, bending, stretching, forming, and welding. But what about these processes? Compared with other processing .

This paper aims at scattering light on the recent research and developments in the sheet metal forming processes over the last two decades. Most of the literature available on . A new generation of fluid pressure forming technology has been developed for the three typical structures of tubes, sheets, and shells, and hard-to-deform material components . Processing technology of sheet metal chassis. According to the basic processing method of sheet metal parts, such as cutting, bending, stretching, forming and welding. This specification describes the process .

The Fraunhofer IPT developed technologies for local, thermal-assisted sheet metal processing (tailored heat) in the manufacturing process. Integrated into transfer or progressive dies, this allows high-strength sheet metal can be .Sheet metal is a comprehensive cold working process for thin metal sheets (usually below 6mm), including shearing, punching/cutting/laminating, folding, welding, riveting, splicing and forming (e.g. car bodies). The distinguishing .

With the more and more extensive application of sheet metal parts, sheet metal processing technology has become a very important part in the process of product .Technology News. Three types of sheet metal parts . Strengthen scientific research on sheet metal manufacturing process. In order to enhance the level of. Yan yifan. 2022-07-22. Read More. Technology News. Advantages of laser welding of sheet metal cabinet. The production process of the processing industry of sheet metal chassis and .The sheet metal processing chassis is an important part of the sheet metal processing industry. The manufacturing process of sheet metal chassis requires a lot of technology. To get sheet metal chassis, we need some specific .

sheet metal manufacturing technology

1 Material selection of sheet metal Sheet metal processing is generally used in the shell of equipment, so the selection of sheet metal is very important. . Sheet Metal Chassis Supplier Menu. Close Menu. Home. About us. MFG Guide. Technology News. Contact us. Improvement measures for sheet metal processing. Technology News Yan yifan — 2022 . Sheet metal parts are commonly referred to as sheet metal parts. Sheet metal refers to a metal plate whose thickness is much smaller than its length. Due to its special geometry and small thickness, it has the advantages of small processing volume, light weight, easy cutting, standardized shape and so on. It can be used [.]Technology News. Three types of sheet metal parts . Strengthen scientific research on sheet metal manufacturing process. In order to enhance the level of. Yan yifan. 2022-07-22. Read More. Technology News. Advantages of laser welding of sheet metal cabinet. The production process of the processing industry of sheet metal chassis and . The following takes you through the process of sheet metal processing: Sheet Metal Boxes. Pre-treatment: Firstly, surface treatment of the product, if there is no position that needs to be sprayed, it needs to be covered in advance; remove the oil and stain on the surface of the product to increase the adhesion of the spraying layer so as to avoid the situation of demoulding.

What are the Characteristics of Outdoor Communication Base Station Battery Cabinet? Deep drawing is a kind of stamping processing method to punch a certain shape of flat blank into various open hollow parts, or take the open hollow parts as blank to reduce the diameter and increase the height. . Technology News Yan yifan — 2022-04-20 . Metal Frames | Sheet Metal Chassis | Laser Cut Sheet Metal Cost | .

Technology News. Surface treatment process of sheet metal chassis . Improve chassis quality during chassis processing. . With the development of social economy and industrial progress, sheet metal parts are more and. Yan yifan. 2022-07-14. Read More. Technology News. Stamping sheet metal cabinet chassis.

The sheet metal stamping process converts hot-rolled or cold-rolled steel plates into the shape needed to make your parts. This technology allows a large number of parts to be produced at the same time, but it can also cause about 15% of raw materials to become waste. The equipment used in this method requires less.Technology News. Surface treatment process of sheet metal chassis . Improve chassis quality during chassis processing. . With the development of social economy and industrial progress, sheet metal parts are more and. Yan yifan. 2022-07-14. Read More. Technology News. Stamping sheet metal cabinet chassis. In the process of product processing and trial production, it is necessary to communicate with customers in a timely manner, and then carry out mass production of products after obtaining the evaluation of corresponding processing. Sheet metal processing is the key technology that sheet metal technicians need to grasp, and sheet metal .

12 years of sheet metal fabrication and cabinet with CNC hardware processing. ISO 9001: 2015 | Engineers with more than 17 years of experience | One-to-one counterpart service . Server chassis. 2024-06-28. Difference between cold working and hot working of metal materials. 2022-12-01. Sheet metal processing technology – riveting. 2022-08-10 . What are the surface treatment methods for sheet metal processing? Let’s briefly understand: 1. Brushed The so-called sheet metal drawing is to put the raw material between the upper and lower belts of the drawing machine.

Sheet metal parts are commonly referred to as sheet metal parts. Sheet metal refers to a metal plate whose thickness is much smaller than its length. Due to its special geometry and small thickness, it has the advantages of small. Sheet metal parts are commonly referred to as sheet metal parts. Sheet metal refers to a metal plate whose thickness is much . Technology News Yan yifan — 2022-07-28 . In addition to strict requirements for the production process of sheet metal chassis processing parts, each sheet metal part needs quality inspection. It is not only necessary to strictly control the size of the sheet metal parts according to the drawings, but also strictly control the appearance .

sheet metal manufacturing process

According to the problems encountered in the actual machining process, the problems needing attention in the structural design of sheet metal are discussed from the following aspects, and the corresponding design . Sheet metal connection mainly adopts welding, threaded connection, riveting and bonding. Welding It is a process method for overall or local heating of weldments or plastic deformation of weldments, or plastic deformation and heating are carried out at the same time to realize lasting connection. It can be divided into gas shielded arc welding, manual [.]Sheet .According to the difference of the sheet metal hardware structure, the chassis processing process can be different, but the total does not exceed the following What time is it 1. Cutting material: ①Shearing machine: It uses a shearing machine to cut simple strips. It is mainly used for mold blanking and forming.JIATONG XJ was found in March 2011, situated in humen town, with a plant area of 8200 square meters, one of China's professional precison sheet metal manufacturer over 10 years. Offerring you One-stop integrated ODM& OEM manufacturing solutions and services including sheet metal machining, welding, painting, silkscreen, assembly.etc, from primary material cutting to .

Compared with other cutting processes, sheet metal processing and cutting technology has the advantages of high speed, high precision and high adaptability, fine cutting seam, small heat affected zone (small deformation), good cutting end face quality, no noise, weld zone group and performance close to the base metal; Moreover, the processing .Precision sheet metal processing; Chassis cabinet sheet metal; Shell sheet metal processing; Electric equipment; Charging pile sheet metal shell; Sheet metal manufacturing processing; . Guangdong Haisen Technology Co., Ltd. Contact: Feng Chan mobiles: 13537811194 Email: . Sheet metal parts refer to sheet metal parts, which can be processed by stamping, bending, stretching and other means. A general definition is the parts with constant thickness in the processing process. For any sheet metal part, it has a certain processing process, which is the so-called process flow. The following describes the basic process [.]Sheet metal parts refer .

Yisheng Precision mainly provides sheet metal processing, laser cutting, CNC stamping, CNC bending, automatic pressing Riveting, welding and other services, the products cover various sheet metal parts such as chassis, cabinets, racks, panels, brackets, shells, radiators, etc. The structural design of sheet metal equipment is closely related to the production process. With the improvement of the automation of sheet metal equipment, we need to constantly understand and contact new sheet metal knowledge, which provides a guarantee for better processing technology of designed parts in the future. Processing and bending of equipment chassis shell MFG Guide Yan yifan — 2022-07-11

metal sheet stamping parts suppliers

metal sheet welding carbide cutting inserts

$20.00

sheet metal chassis processing technology|sheet metal forming