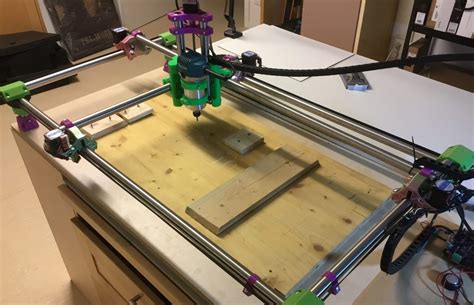

building my cnc router part i In this project, I show you how I built my DIY CNC machine. All moving parts of the DIY CNC router are running on ball bearings while the structural parts are made with natural . USX MOUNT UL Listed TV Wall Mount Tilting Brackets for Most 37"-90" Flat Curved Screen TVs with Max VESA 600x400mm, Weight Capacity 132lbs, Low Profile Space Saving for 16", 24" Stud

0 · make your own cnc machine

1 · homemade cnc router plans free

2 · homemade cnc router machine

3 · do it yourself cnc machine

4 · cnc router homemade video

5 · build your own cnc router

6 · build your own cnc machine

7 · build your own cnc

Looking for 2013 Toyota Tundra Junction Boxes? We offer both aftermarket and OEM 2013 Toyota Tundra Junction Boxes to get your car back to its peek performance.

Thought I'd make a video showing all the pictures I took while building my CN. This video is part 1 in a 4 part series on building a new CNC Router. This video covers the design and components that I have decided on using.Link to the pl.Completely build a CNC router from the ground up without plans, just your hands, some cheap materials and basic tools, and common sense. Did I mention you . Building my CNC router from scrap.Starting with aluminium profiles of 80 mm x 40 mm and 4 mm width to make the router frame.

In this project, I show you how I built my DIY CNC machine. All moving parts of the DIY CNC router are running on ball bearings while the structural parts are made with natural .When designing a CNC router it is helpful to ask yourself a couple of questions. Here you will find the design process I went through for my CNC router. What type of CNC router do you want to build? There basically are two types of . Thought I'd make a video showing all the pictures I took while building my CN.

This video is part 1 in a 4 part series on building a new CNC Router. This video covers the design and components that I have decided on using.Link to the pl.Completely build a CNC router from the ground up without plans, just your hands, some cheap materials and basic tools, and common sense. Did I mention you don't need plans? Building my CNC router from scrap.Starting with aluminium profiles of 80 mm x 40 mm and 4 mm width to make the router frame.

make your own cnc machine

In this project, I show you how I built my DIY CNC machine. All moving parts of the DIY CNC router are running on ball bearings while the structural parts are made with natural materials, namely birch plywood and solid beech wood.When designing a CNC router it is helpful to ask yourself a couple of questions. Here you will find the design process I went through for my CNC router. What type of CNC router do you want to build? There basically are two types of CNC routers: .In general if someone refers to a CNC “milling” machine they are referring to a metal cutting machine and if they say it’s a CNC "router" it means a machine made to cut wood, plastic or other soft materials. This instructable will show you how to build a CNC router.

A DIY CNC router may sound like a fun project, but it can be a challenge even for discerning makers. Here's what you need to know.Building your own 3-Axis CNC router is both fun and educational. These plans document all the steps I followed to make my DIY CNC Router. This is the second DIY CNC Router I made, after learning a lot from building the first version. This is a very good router that can be built at a reasonable price using readily available materials. This

cnc machine g codes pdf

A compact router, baltic birch plywood, some basic hardware, and an off-the-shelf electronics kit are all you need to build your own computer-controlled router. This project is ideal for tech-savvy woodworkers looking to add a CNC router to their shop or beginners who want to give this type of woodworking technology a try. Thought I'd make a video showing all the pictures I took while building my CN.This video is part 1 in a 4 part series on building a new CNC Router. This video covers the design and components that I have decided on using.Link to the pl.Completely build a CNC router from the ground up without plans, just your hands, some cheap materials and basic tools, and common sense. Did I mention you don't need plans?

Building my CNC router from scrap.Starting with aluminium profiles of 80 mm x 40 mm and 4 mm width to make the router frame. In this project, I show you how I built my DIY CNC machine. All moving parts of the DIY CNC router are running on ball bearings while the structural parts are made with natural materials, namely birch plywood and solid beech wood.When designing a CNC router it is helpful to ask yourself a couple of questions. Here you will find the design process I went through for my CNC router. What type of CNC router do you want to build? There basically are two types of CNC routers: .

In general if someone refers to a CNC “milling” machine they are referring to a metal cutting machine and if they say it’s a CNC "router" it means a machine made to cut wood, plastic or other soft materials. This instructable will show you how to build a CNC router.

A DIY CNC router may sound like a fun project, but it can be a challenge even for discerning makers. Here's what you need to know.Building your own 3-Axis CNC router is both fun and educational. These plans document all the steps I followed to make my DIY CNC Router. This is the second DIY CNC Router I made, after learning a lot from building the first version. This is a very good router that can be built at a reasonable price using readily available materials. This

homemade cnc router plans free

cnc machine hole in steel with core saved

cnc machine hackaday

A separate coax or coaxes will need to be installed for the Tv antenna reception to the Tv. As an example , if one coax is delivering the cable internet to the cable modem , then .

building my cnc router part i|build your own cnc router