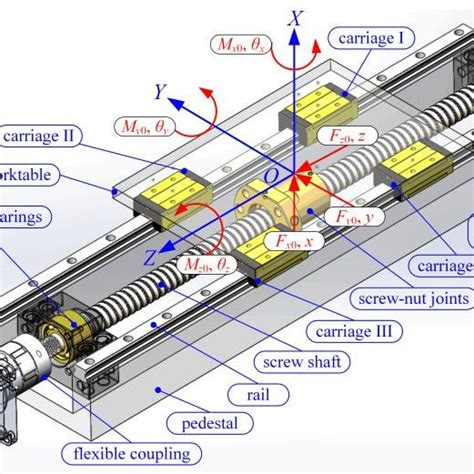

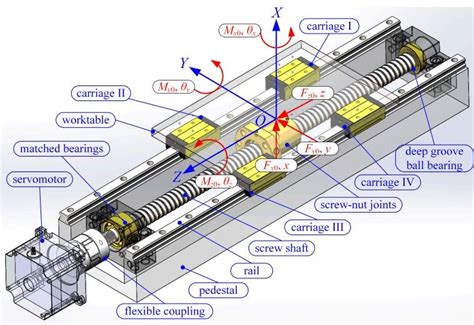

ball screw vibrating on cnc machine Ya Zhang and a team of researchers conducted an in-depth analysis of the natural frequencies and transient response of a ball screw drive using a 6 Degree of Freedom model. CNC (computer numerical control) machining is a popular manufacturing process that uses computerized controls to automate parts production. Today, we’ll look at what CNC machining is, how it works, and the advantages and challenges of this process.

0 · vibration of balls

1 · ball screw vibration

2 · ball screw drive vibration

3 · ball screw drive

Metal fabrication is the art and science of building metal structures by cutting, bending, and assembling processes. This intricate craft involves transforming raw metal materials into pre-designed shapes and products, showcasing a blend of technical skills and creativity.

Heat discoloration on lead or balls of ball screw. This is often cause by poor lubrication or. Vibration when moving caused by bent ball screws, misalignment of bearing housings or possibly just an unlevel machine. In this paper, we propose a method to monitor the preload of an operational ball screw drive system mostly used in CNC machine tools by evaluating the natural frequency of . Ball screw drive systems are widely applied in the majority of CNC machine tools for the time being. In the process of high-speed machining, the vibration of the ball-screw drive . Ya Zhang and a team of researchers conducted an in-depth analysis of the natural frequencies and transient response of a ball screw drive using a 6 Degree of Freedom model.

Identify common problems that can occur with ball screws in CNC machines, such as backlash, excessive noise, and wear. Provide step-by-step troubleshooting guides to help readers . I’ve been seeing some ball screw vibrations on the x and y axis of the HDM while doing rapids. The vibrations come from nearing the natural resonant frequencies of the ball . We propose a comprehensive modeling approach to investigate the rigid-flexible coupling vibration of a Ball-screw-drive spindle system (BSDSS).CNC machine vibration problems can have a detrimental impact on productivity, accuracy, and surface finish quality. By understanding the causes and implementing the appropriate .

I am wondering what to use to lubricate the rails, balls screws and blocks? They included grease nipples but in reading about them I found a few completely conflicting suggestions. My cnc makes vibration noise when i get the speed . The ball screws used in the feed systems of the CNC machines work with continuously increasing cutting speed. When the speed of the balls reaches certain level, the repetitive shocks (impact forces) generated by the balls in the “transient phase” of the balls’ motion increase the system vibrations.Heat discoloration on lead or balls of ball screw. This is often cause by poor lubrication or. Vibration when moving caused by bent ball screws, misalignment of bearing housings or possibly just an unlevel machine.

In this paper, we propose a method to monitor the preload of an operational ball screw drive system mostly used in CNC machine tools by evaluating the natural frequency of the screw nut in the axial direction and the corresponding working table displacement.Ball screw drive systems are widely applied in the majority of CNC machine tools for the time being. In the process of high-speed machining, the vibration of the ball-screw drive system will affect the stability of the control system and the machining accuracy of CNC machine tools. Ya Zhang and a team of researchers conducted an in-depth analysis of the natural frequencies and transient response of a ball screw drive using a 6 Degree of Freedom model.

Identify common problems that can occur with ball screws in CNC machines, such as backlash, excessive noise, and wear. Provide step-by-step troubleshooting guides to help readers diagnose and resolve these issues effectively. I’ve been seeing some ball screw vibrations on the x and y axis of the HDM while doing rapids. The vibrations come from nearing the natural resonant frequencies of the ball screw systems, and it changes as the carriage travels along the length of the ball screws. We propose a comprehensive modeling approach to investigate the rigid-flexible coupling vibration of a Ball-screw-drive spindle system (BSDSS).CNC machine vibration problems can have a detrimental impact on productivity, accuracy, and surface finish quality. By understanding the causes and implementing the appropriate solutions, manufacturers can minimize or eliminate these problems.

vibration of balls

I am wondering what to use to lubricate the rails, balls screws and blocks? They included grease nipples but in reading about them I found a few completely conflicting suggestions. My cnc makes vibration noise when i get the speed around 1800mm/min (its a . The ball screws used in the feed systems of the CNC machines work with continuously increasing cutting speed. When the speed of the balls reaches certain level, the repetitive shocks (impact forces) generated by the balls in the “transient phase” of the balls’ motion increase the system vibrations.Heat discoloration on lead or balls of ball screw. This is often cause by poor lubrication or. Vibration when moving caused by bent ball screws, misalignment of bearing housings or possibly just an unlevel machine. In this paper, we propose a method to monitor the preload of an operational ball screw drive system mostly used in CNC machine tools by evaluating the natural frequency of the screw nut in the axial direction and the corresponding working table displacement.

Ball screw drive systems are widely applied in the majority of CNC machine tools for the time being. In the process of high-speed machining, the vibration of the ball-screw drive system will affect the stability of the control system and the machining accuracy of CNC machine tools.

Ya Zhang and a team of researchers conducted an in-depth analysis of the natural frequencies and transient response of a ball screw drive using a 6 Degree of Freedom model.

Identify common problems that can occur with ball screws in CNC machines, such as backlash, excessive noise, and wear. Provide step-by-step troubleshooting guides to help readers diagnose and resolve these issues effectively. I’ve been seeing some ball screw vibrations on the x and y axis of the HDM while doing rapids. The vibrations come from nearing the natural resonant frequencies of the ball screw systems, and it changes as the carriage travels along the length of the ball screws.

We propose a comprehensive modeling approach to investigate the rigid-flexible coupling vibration of a Ball-screw-drive spindle system (BSDSS).CNC machine vibration problems can have a detrimental impact on productivity, accuracy, and surface finish quality. By understanding the causes and implementing the appropriate solutions, manufacturers can minimize or eliminate these problems.

electrical enclosure filter fan

ball screw vibration

CNC machining is a subtractive manufacturing process in which a computer program guides different tools to create a product. The tools include drills, lathes, and mills that cut away at a workpiece to achieve desired specifications.

ball screw vibrating on cnc machine|ball screw vibration