applications of cnc machine CNC machines utilize advanced technology, including computer programming and automation, to perform precise and accurate manufacturing processes. CNC machines follow a predefined process to remove material . $8.25

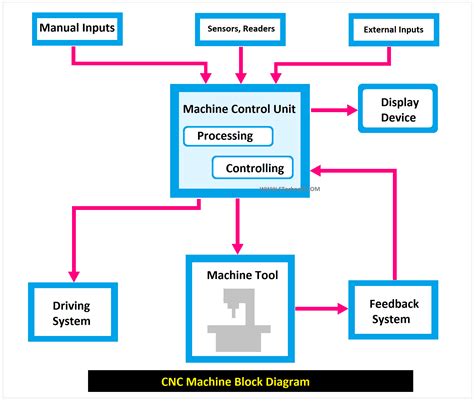

0 · schematic diagram of cnc machine

1 · products made by milling machine

2 · industries that use cnc machines

3 · different type of cnc machines

4 · computer numerical control cnc machines

5 · companies that use cnc machines

6 · cnc machine work needed

7 · application of cnc lathe machine

Metallization Process in which a thin layer of metal is formed which is used to make interconnections between the components on the chip as well as interconnections between the components and the outside world. In general metallization applications are divided into three groups, Interconnects.

Since CNC machines can process almost any type of material, their applications are near limitless. From direct part production to rapid prototyping, this article looks at the various robust applications of CNC machining. CNC (Computer Numerical Control) machining is the process of using a machine to automatically remove material from raw stock based on a set of computer-generated instructions. It can be performed on almost any . CNC machines utilize advanced technology, including computer programming and automation, to perform precise and accurate manufacturing processes. CNC machines follow a predefined process to remove material .

cantex weatherproof electrical box

What Are the Applications of CNC Machining? These are some common applications of CNC machining: CNC machining emerges as an invaluable tool in an industry where absolute precision is absolutely non . Have you ever wondered how CNC machines shape our world? These versatile tools revolutionize manufacturing, handling tasks from simple drilling to complex milling. In this article, we’ll explore the various types of CNC .

CNC machines, short for Computer Numerical Control machines, are crucial in modern manufacturing. They are like super-precise robots controlled by computers, ensuring top-notch efficiency and accuracy far beyond what . CNC Machining is short for Computer Numerical Control Machining, and these machines can achieve an accuracy and consistency that would be hard to match with a manual process. Using pre-programmed . Computer Numerical Control (CNC) machines have revolutionized manufacturing, offering unmatched precision, efficiency, and versatility. In this article, we will delve into what CNC machines.

Let’s navigate through the different types of CNC machining and uncover the unique attributes and applications of each. Milling: Milling machines use rotary cutters to remove material. They’re versatile and can produce everything from . Since CNC machines can process almost any type of material, their applications are near limitless. From direct part production to rapid prototyping, this article looks at the various robust applications of CNC machining.

CNC machining is nothing short of a miracle for manufacturers, providing high-speed manufacturing with complete automation and ultra-high precision. The countless benefits of the CNC machining process have made it applicable in many manufacturing industries. CNC (Computer Numerical Control) machining is the process of using a machine to automatically remove material from raw stock based on a set of computer-generated instructions. It can be performed on almost any material from expanded polyurethane foam to . CNC machines utilize advanced technology, including computer programming and automation, to perform precise and accurate manufacturing processes. CNC machines follow a predefined process to remove material from a blank or workpiece, resulting in the production of intricate and complex parts. What Are the Applications of CNC Machining? These are some common applications of CNC machining: CNC machining emerges as an invaluable tool in an industry where absolute precision is absolutely non-negotiable.

Have you ever wondered how CNC machines shape our world? These versatile tools revolutionize manufacturing, handling tasks from simple drilling to complex milling. In this article, we’ll explore the various types of CNC machines, their unique applications, and the technology that drives them. CNC machines, short for Computer Numerical Control machines, are crucial in modern manufacturing. They are like super-precise robots controlled by computers, ensuring top-notch efficiency and accuracy far beyond what manual work can achieve. CNC machining has made once-impossible tasks easy.

CNC Machining is short for Computer Numerical Control Machining, and these machines can achieve an accuracy and consistency that would be hard to match with a manual process. Using pre-programmed computer software, CNC machines can produce items more quickly and with better surface finishes.

Computer Numerical Control (CNC) machines have revolutionized manufacturing, offering unmatched precision, efficiency, and versatility. In this article, we will delve into what CNC machines.Let’s navigate through the different types of CNC machining and uncover the unique attributes and applications of each. Milling: Milling machines use rotary cutters to remove material. They’re versatile and can produce everything from simple shapes to complex geometries. Since CNC machines can process almost any type of material, their applications are near limitless. From direct part production to rapid prototyping, this article looks at the various robust applications of CNC machining.

CNC machining is nothing short of a miracle for manufacturers, providing high-speed manufacturing with complete automation and ultra-high precision. The countless benefits of the CNC machining process have made it applicable in many manufacturing industries. CNC (Computer Numerical Control) machining is the process of using a machine to automatically remove material from raw stock based on a set of computer-generated instructions. It can be performed on almost any material from expanded polyurethane foam to . CNC machines utilize advanced technology, including computer programming and automation, to perform precise and accurate manufacturing processes. CNC machines follow a predefined process to remove material from a blank or workpiece, resulting in the production of intricate and complex parts.

What Are the Applications of CNC Machining? These are some common applications of CNC machining: CNC machining emerges as an invaluable tool in an industry where absolute precision is absolutely non-negotiable. Have you ever wondered how CNC machines shape our world? These versatile tools revolutionize manufacturing, handling tasks from simple drilling to complex milling. In this article, we’ll explore the various types of CNC machines, their unique applications, and the technology that drives them. CNC machines, short for Computer Numerical Control machines, are crucial in modern manufacturing. They are like super-precise robots controlled by computers, ensuring top-notch efficiency and accuracy far beyond what manual work can achieve. CNC machining has made once-impossible tasks easy.

CNC Machining is short for Computer Numerical Control Machining, and these machines can achieve an accuracy and consistency that would be hard to match with a manual process. Using pre-programmed computer software, CNC machines can produce items more quickly and with better surface finishes.

Computer Numerical Control (CNC) machines have revolutionized manufacturing, offering unmatched precision, efficiency, and versatility. In this article, we will delve into what CNC machines.

schematic diagram of cnc machine

It's a bit tough to tell but this looks like GAW chainlink. That means galvanized after weaving. It's made by using a weaving machine (usually Bergandi in North America) to weave unfinished raw steel wire. Then it's essentially dragged .

applications of cnc machine|companies that use cnc machines