cnc milling machine parts and functions Parts of a CNC milling machine include a column, base, knee, power feed mechanism, a work table, ram, spindle, milling tool, milling chuck, CNC controller, and an overhanging arm along with arbor support in case of . Metal fabrication is a manufacturing process used to shape metal into parts or end products. It usually consist of three phases: 1) design, where shop drawings are created to the intended measurements; 2) fabrication, which involves .

0 · schematic diagram of cnc machine

1 · milling machine parts list

2 · cnc milling machine diagram

3 · cnc machine parts list pdf

4 · cnc machine parts diagram

5 · cnc lathe parts diagram

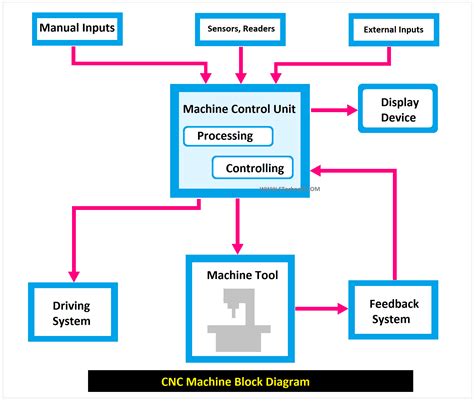

6 · block diagram of nc machine

7 · block diagram of cnc machine

Surface-mounted electrical boxes for all electrical fixtures must be raintight/weatherproof. Exterior light fixtures do not require GFCI protection. Low-voltage lighting systems must be listed by an approved testing agency as an entire system or assembled from individual components that are listed.What Is an Electrical Subpanel? An electrical subpanel is also called a satellite circuit breaker panel. It’s often installed in a separate location .

In this article, I have covered the standard CNC milling parts, tools commonly used with the machine, factors affecting the cost of a CNC mill, and how CNC machining works. I hope that you’ve got the basics of this important .

Parts of a CNC milling machine include a column, base, knee, power feed mechanism, a work table, ram, spindle, milling tool, milling chuck, CNC controller, and an overhanging arm along with arbor support in case of . CNC milling machines are equipped with several essential parts that work in unity to facilitate the machining process. These machines use computer numerical control (CNC) and automated features to control the .

Although the milling operations on the two styles of milling machines might vary, the milling machine parts that make them up have much in common. We’ve created a list of the essential parts of a CNC milling machine .In this article, we’ll take a high-level look at CNC machine parts and functions. The links you see will provide more details on that topic. What is a CNC Machine? A CNC machine utilizes computer programming to direct a machine’s tool .

Understand the parts and functions of CNC machines. From controllers and motors to tool holders and coolant systems, get a detailed explanation of each component to enhance your knowledge. . The CNC . Auxiliary functions related to machine operations control several critical aspects of CNC machines, such as spindle rotation, gear range changes, automatic tool changes, coolant operations, and movement of tailstocks or .What are the Parts of a CNC Machine? Bed: Typically constructed from cast iron for enhanced durability and strength, the bed is the machine’s foundation, supporting all components.. Spindle: Inside the machining area, the .Notable aspects of CNC milling machines: CNC Technology: Automated processes driven by computer programs. Precision: High accuracy in creating complex and delicate components. Efficiency: Capable of running 24/7, increasing productivity. Universal Milling Machines. Universal milling machines combine the capabilities of both vertical and .

CNC milling machines are among the most versatile and widely used in the industry. Call (407) 298-9171; AS 9100 D / ISO 9001:2015 Certified; Connect with us: . CNC lathes are specifically designed for producing cylindrical parts. By rotating the workpiece against a fixed cutting tool, these machines can create smooth, round objects like .

The significance for CNC machine parts and their function shows that this machining method has taken over all forms of old manufacturing. . The CNC milling machine has a vast and composed structure, it performs many tasks simultaneously. CNC machines are the total opposite of older machining methods. Computer numerical control machines have . CNC Milling Machine CDM7113A 3 Axis CNC Milling Machine 12000RPM High Speed with Engraving Function for Household DIY Aircraft Model Parts Watch Parts Processing . milling, tapping, cutting function CNC milling machine with small footprint, high precisio, highly adaptable; Self-contained system and operation panel. Systematic vertical panel . Parts of CNC Machine + Function – Some significant components and elements that contribute to the machine’s efficacy are present in machine tools with CNC systems. Before utilizing any CNC machine, one must be familiar with the control code, according to a previous post. We have looked at two G-codes and two M-codes.

Hello! To kick-start the incorporation of CNC machines courses and programming, you will need necessary and adequately strong machines such as CNC milling machines, CNC lathes, and CNC routers. These machines will provide a solid foundation for your faculty of engineering’s teaching and learning content. Best regards! Reply

CNC (Computerized Numerical Control) machining is a technology that allows machines to perform precise cutting, engraving, drilling, or milling operations based on preset instructions, m-code is a component of the CNC programming language used to control various functions during the machining process. This article provides a comprehensive understanding . A CNC milling machine is a marvel of engineering, combining various components to transform raw material into intricate shapes and designs. The machine control unit (MCU) is pivotal in managing the machine’s movements and operations, while the core components function in unison to enable efficient operation and accurate cnc machine work capabilities. This article will describe the different parts of a CNC machine. Some parts are common between lathes and mills, like the control unit, driving system, and feedback system, while others are specific to a certain type of machine. For example, tailstocks and headstocks are only found on CNC lathes. 1. Input Device 8. For synchronous milling the rotation direction of the milling tool and the feed movement of the work part are parallel. The tooth of the milling cutter immediately penetrates into the work part. Since the milling tool cutting edge is exposed to impact forces the feed drive needs to be play free. Several cutters should always be in operation. The surface quality is flatter and .

The saddle in milling machines plays a significant role in various milling machine processes. It offers essential functions that contribute to the overall efficiency and accuracy of the milling process. Let’s take a closer look at the key roles and uses of the saddle in milling machines. Precise Positioning and Feeding of the Workpiece Understanding these parts and their functions is crucial for efficient and safe operation of a milling machine. The milling machine is a powerful tool used for cutting and shaping metals. Understanding the anatomy and . The function of the tool changer in CNC milling is to automate the process of switching between different cutting tools as required by the machining operations. This system significantly enhances productivity by reducing .

coke metal box 6x3inches

CNC Milling Machine Parts. There are various types of milling machines with a variety of particular functions based on certain specifications. Each machine contains a cutter that can be operated at a various range of speed in order to form the required shape. Computer Numerical Control (CNC) Milling Machines are also available in different sizes.That being said, every CNC milling machine has some basic parts that allow it to function as intended. I have listed the standard and most common CNC milling machine parts you need to know. 1) CNC Controller. The CNC controller is the brain of the machine. It is responsible for controlling the movements and functions of the CNC milling machine.Understanding the Functions of CNC Machine Parts\ In this section, delve into the functions of each CNC machine part mentioned in the previous section. . Equipped with 3-4-5 axis CNC milling and CNC turning machines, which enable us to handle even more complex parts with high precision. Rapid Injection molding. Low investment, fast lead time . The principle parts of milling machine are given: Base The base of the machine is Grey iron casting accurately machined on its top and bottom surface and serves as a foundation member for all the other parts which rest upon it. . Milling Machine Parts and their Function. Author: ninjacraze. Dec 24, 2009. . I AM PARTCIPAT IN THE SEMANER CNC .

The key elements of a CNC machine are described as the input device, machine control unit, machine tool, driving system, feedback devices, and display unit. The document also covers the basic programming and operation of CNC machines using G and M codes to control axes movement, feed rates, spindle speeds, tool changes, and other functions.3. Understanding the Functions of CNC Lathe Machine Parts\ 3.1 Bed and Headstock Functions\ 3.2 Tailstock and Carriage Functions\ 3.3 Chuck and Spindle Functions\ 3.4 Tool Turret and Tooling Functions\ 3.5 Control Panel and Software Functions\ 3.6 Coolant System Functions . 4. Common CNC Lathe Machine Operations\ 4.1 Facing\ 4.2 Turning\ 4.3 . CNC Milling Machines. CNC milling machines are designed to perform tasks such as drilling, cutting, and shaping materials. They have several essential parts that enable them to execute these functions with precision: Spindle Motor: The spindle motor powers the cutting tool, providing the necessary torque and speed for milling operations. It is .

Understanding the components of a CNC milling machine is essential for operators, engineers, and anyone involved in the manufacturing process. In this article, we'll explore the key parts that make up a CNC milling machine and their functions. What Are the Essential Parts of a CNC Milling Machine? The essential.CNC Milling Machines: First, CNC milling machines use rotary cutting tools to remove material from a workpiece and make it into a shape or form that the user wants. These CNC machines help cut, shape, and drill different kinds of materials. They are often used to make precise and complicated parts. Key Components:12 Common Types of Milling Machines and Their Functions. . and details in materials to turn them into vehicles or mechanical parts. Modern CNC milling machines are assembled as both horizontal and vertical machining centers, and can be made with materials like plastics, ceramics, composites, and metals. Technical features include automatic .

Welcome to a fascinating journey into the inner workings of CNC machines! In this article, we will take a detailed look at the anatomy of a CNC machine, exploring its main parts and functions. Whether you are a seasoned CNC operator or someone new to

schematic diagram of cnc machine

Prototype productionThe EDM process is most widely used by the mold-making, tool, and die industries, but is becoming a . See more

cnc milling machine parts and functions|cnc machine parts diagram