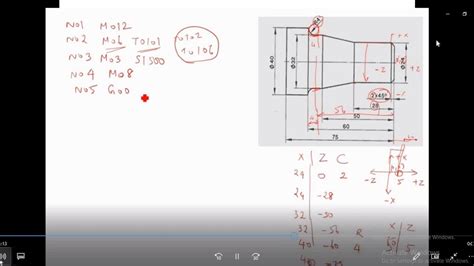

cnc milling machine programming examples pdf A PowerPoint presentation on CNC milling programming basics, commands, cycles, and features. Includes examples of G-codes, M-codes, and tool motion commands.

Gather Necessary Materials: Get all tools and materials needed, such as UF-B cable, connectors, junction boxes (if required), and digging equipment. Excavate the Trench: Dig a wide enough trench at least 24 inches deep for direct burial.

0 · cnc turning program examples pdf

1 · cnc turn mill programming pdf

2 · cnc programming manual pdf

3 · cnc programming handbook pdf download

4 · cnc programming handbook pdf

5 · cnc programming for beginners pdf

6 · cnc programming codes pdf download

7 · cnc programming codes list pdf

Round Hole Perforated Metal, the most popular type of McNICHOLS ® Perforated Metal, is available in staggered and straight centers and various diameters, gauges and sheet size options. This versatile hole type appears in a wide range of applications, from industrial to .Choose from our selection of metal U-channels, including low-carbon steel U-channels, architectural 6063 aluminum U-channels, and more. In stock and ready to ship.

cnc turning program examples pdf

This programming workbook provides basic principles necessary to program the Haas mill. It is not intended as an in-depth study of all ranges of the machine use.

Basic Programming. A typical CNC program has (3) parts: 1) Preparation: This .

The examples described in this manual are for learning purposes. Before using them in industrial applications, they must be properly adapted making sure that the safety regulations are fully . CNC Machine Programming Course / PDF eBook Includes examples, Fanuc dialect, and more. Learn to read and write g-code in this 16 chapter tutorial course and eBook.

This manual provides basic programming principles necessary to begin program-ming the HAAS C.N.C. Milling Machine. In a fiCNCfl (Computerized Numerical Control) machine, the tool is .A PowerPoint presentation on CNC milling programming basics, commands, cycles, and features. Includes examples of G-codes, M-codes, and tool motion commands.Learn the fundamentals of CNC programming for milling and turning machines with this book by Steve Krar and Arthur Gill. It covers the Cartesian coordinate system, point-to-point and .Basic Programming. A typical CNC program has (3) parts: 1) Preparation: This portion of the program selects the work and tool offsets, selects the cutting tool, turns on the coolant, sets spindle speed, and selects absolute or incremental .

cnc turn mill programming pdf

The first sections of the manual take you through the very basics of what a CNC Mill is and what operations it can do, the basics of how the machine works, what G - Code is, the different .In this blog post, we will delve into the world of CNC milling machine programming and explore various examples to help you master this essential skill. Additionally, we will provide a .This book offers a set of exercises to perform alone or in a training session in order to consolidate your knowledge of numerical control milling programming.

Programming and Operating Manual (Turning) Programmers and operators of turning machines Programming and Operating Manual (Milling) Programmers and operators of milling machines Programming and Operating Manual (ISO Turn-ing/Milling) Programmers and operators of turning/milling machines Programming and Operating Manual (Manual Ma-CNC Mill Program Example. A very simple cnc milling machine programming tutorial for beginner level cnc machinists. An easy to understand cnc mill programming code. This is a cnc g code example without the use of any cnc .This manual is a beginners guide to writing macro programs for CNC. It explains the basic functionality of the macro programming language. I will assume you have some knowledge of G-Code programming already, as this is essential before learning the advanced programming techniques provided by the macro language. Section 1. What is macro programming

Modern CNC Machine Accuracy ØAccuracy of CNC machines depends on their rigid construction, care in manufacturing, and the use of ball screws to almost eliminate slop in the screws used to move portions of the machine. These pictures show the precision balls which re-circulate in the nut. Photo courtesy Thompson Ball Screw. Graphic courtesy BSA Co.

A typical CNC program has (3) parts: 1) Preparation: This portion of the program selects the work and tool offsets, selects the cutting tool, turns on the coolant, sets spindle speed, and selects absolute or incremental positioning for axis motion. 2) Cutting: This portion of the program defines the tool path and feed rate for the cutting operation. 3) Completion: This portion of the program .and information is necessary before attempting to program on the machine. This programming manual is meant as a supplementary teaching aid to users of the HAAS Mill. The information in this workbook may apply in whole or in part to the operation of other CNC machines. Its use is intended only as an aid in the operation of the HAAS Milling Machine.• Also when finishing the floor of a feature or face milling thin material the down force can assist in stabilizing the part. • Problematic with old manual lathes because of backlash in gears. • Preferred method for CNC. For outside milling move around the work clockwise. When pocket milling move around the work counterclockwise.

M Codes “G” stands for Geometry; hence, the G-Code commands are responsible for the movements of the machine that create the geometry of the part.“M” stands for Machine (or Miscellaneous), and the M-Codes are responsible for Machine commands that cause particular operations of the equipment. Unlike G-codes, which can appear multiple times on the same .• write the part program for the turning. 8.2 EXAMPLES Example 8.1 The component to be machined is shown in Figure 8.1. Prepare a CNC part program to machine it on any turning center using the ISO standard G-codes. You may decide the program zero to be used for the component. Write the program using the initial tool position.

CNC Mill Program Example A very simple cnc milling machine programming tutorial for beginner level cnc machinists. An easy to understand cnc mill programming code. . CNC Milling programming example code with drawing, which shows how G41 Cutter Radius Compensation Left is used in a cnc mill program. CNC Mill Program (G41 Cutter Radius .CNC Milling programing guide.pdf - Free download as PDF File (.pdf), Text File (.txt) or read online for free. The document is a guide for teaching CNC programming. It provides concise explanations and examples to help instructors teach the fundamentals of CNC programming without relying on manuals that are too technical or specific. It is part of a free CNC learning kit .

word refers to a specific cutting/movement command or machine function. The programming language recognised by the CNC, the machine controller, is an I.S.O. code, which includes the G and M code groups. Each program word is composed from a letter, called the address, along with a number. Part Program example - (Lathe CAM Designer - ØØ5Ø.LCD)

cnc programming manual pdf

using this course have been taught to set up, program, and operate a CNC mill in less than 24 hours of combined classroom/lab time ; including instruction in HSMWorks. This economy of instruction makes CNC accessible to almost anyone: from working engineers to studentsthe machine zero. We use a floating zero referred to as the part zero or part origin. We touch off the face and diameter, and store the offset from the machine zero in X and Z register of the Tool Offsets Page. (Not the same as mill which uses G54!)G Code is a special programming language that is interpreted by Computer Numerical Control (CNC) machines to create motion and other tasks. It is a language that can be quite complex at times and can vary from machine to machine. The basics, however, are much simpler than it first appears and for the most part follows an industry adopted standard. The key elements of a CNC machine are described as the input device, machine control unit, machine tool, driving system, feedback devices, and display unit. The document also covers the basic programming and operation .

Click CNC Programming Examples. These are the different CNC programming examples we have both turning and milling. CNC Programming Examples Turning. G94 Facing. Milling. G81 Drilling Cycle. G73 Peck Drilling Cycle. G83 Deep Hole Peck Drilling Cycle. G82 Drill With Dwell Cycle. G84 Rigid Tapping. Examples from HaasMANUAL PART PROGRAMMING TyPES OF MANUAL PROGRAMMING: POINT TO POINT, CONTOURING, 3-D. (3-D programming, only with the help of a computer) . WRITE THE PART PROGRAM IN A STANDARD FORMAT SPECIAL MANUSCRIPT AND FLEXO WRITER – TAPE, LISTING etc. (Nowadays, these are is not required) MOSTLY POINT TO POINT programming .Fanuc Cnc Programming PDF - Free download as PDF File (.pdf), Text File (.txt) or read online for free. Fanuc cnc programming pdf documents include manuals on programming Fanuc CNC systems, examples of CNC programming codes, and guides for maximizing productivity with Fanuc controls. Documents cover topics like macro programming, G-code programming for .Information about the structure and contents of the documentation. The NC programming is described in two manuals: 1. Fundamentals The Programming Manual "Fundamentals" is intended for use by skilled machine operators

Milling Machine The milling machine has always been one of the most versatile machine tools used in industry (Fig. 5). Operations such as milling, contouring, gear cutting, drilling, boring, and reaming are only a few of the many operations which can be performed on a milling machine. The milling machine can be programmed on three axes:

using this course have been taught to set up, program, and operate a CNC mill in less than 24 hours of combined classroom/lab time ; including instruction in HSMWorks. This economy of instruction makes CNC accessible to almost anyone: from working engineers to studentsIntroduction to milling machine & its parts. Different operations of milling. Plain milling Step milling Slot malling Pocket milling . Fundamentals of CNC programming Part programming techniques Machining practice on CNC Milling Practice session at Industry Module-6 Cnc Milling - Download as a PDF or view online for free . It describes the theory of CNC milling machines, including their characteristics, geometry, coordinate systems, zero and reference points, and programming structure. . Linear feed motion) or a real value (e.g. X+60 : Approaching the target coordinate X=60). Example of part program .Cybermill CNC milling machine. Once program is completed, simulate the program for verification, and then run the program on the Cybermill using a pen as tool. The “Walli” is available on all four PC’s and does not require the part program number or the header information as in NUM750F.

It’s full of examples on a case-by-case basis for all the common g code commands used by your machine tool. Want completed programs? No worries, here’s a bunch of example gcode files you can try on your cnc machine to gain a better understanding of g-codes. Note that each specific machine may have its own dialect for g-codes.G-Code is the language used to control CNC machines. It's one type of CNC programming that CNC programmers use, the other type being CAM programming. Your machine's CNC controller probably executes g-code, although there are other possibilities--Heidenhain, Mazak, and others have proprietary formats. Some machines

cnc programming handbook pdf download

sheet metal fabrication nashville

A junction box contains two 3-in. raceways on the left side, one 3-in. raceway on the right side, and one 3-in. raceway on the bottom. The conductors from the lower 3-in. raceway on the left wall are pulled through the 3-in. raceway on the right wall.Use this junction box sizing calculator to determine the recommended dimensions of a junction box depending on the number of straight and angle pulls entering it and meet the National Electrical Code®.

cnc milling machine programming examples pdf|cnc programming handbook pdf