cnc turning plastic part Based on the CNC machining method — CNC drilling, CNC turning, or CNC milling — engineers must adhere to different guidelines to produce superior plastic CNC machined parts. In this article, we’ll break each of them down. Welding thin metal is challenging. There is no denying that. But, if you practice and use the tips we shared in this article, you’ll get the best chance for success. After you inevitably burn through some scrap sheets of metal and warp others, you’ll gain more experience and learn . See more

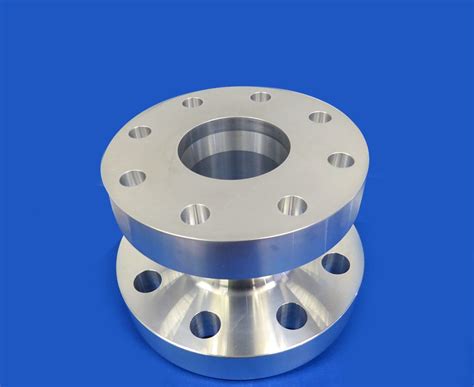

0 · precision cnc machined parts

1 · grinding for precision turned parts

2 · cnc turning services near me

3 · cnc turning machining parts factory

4 · cnc turning machining

5 · cnc turning machine parts

6 · cnc turned parts manufacturer

7 · cnc turned components

Re: TFL Code 31 Entering stopping in box junction SW18 West Hill Fire Station « Reply #16 on: July 24, 2023, 07:33:53 pm » It can take up to 2 - 3 months to get a response .

Based on the CNC machining method — CNC drilling, CNC turning, or CNC milling — engineers must adhere to different guidelines to produce superior plastic CNC machined parts. In this article, we’ll break each .

CNC plastic machining is a technique whereby plastic cutting tools are guided by computer numerical control technology. The process, also known as CNC, involves accurate movements of tools and workpieces and . Based on the CNC machining method — CNC drilling, CNC turning, or CNC milling — engineers must adhere to different guidelines to produce superior plastic CNC machined parts. In this article, we’ll break each of them down. CNC plastic machining is a technique whereby plastic cutting tools are guided by computer numerical control technology. The process, also known as CNC, involves accurate movements of tools and workpieces and predetermined computer instructions that make different plastics including parts and products. Plastic machining factories rely on computer-controlled devices to form raw materials into designated pieces. It is this technique, known for its accuracy, which works particularly well with plastics, giving one a cheaper option of .

Learn how to select the right plastic for CNC machining. Avoid pitfalls, ensure optimal performance, and reduce costs for your CNC machined parts with our comprehensive guide.Plastic CNC machining is a subtractive manufacturing method that involves placing a solid block of plastic against a moving cutting tool that removes material from the block. In order to shape the final product, the cutting tool follows a predetermined path directed by a digital design file.

precision cnc machined parts

CNC plastic machining utilizes a subtractive process to gradually cut a plastic block to the desired shape and precision. Depending on the plastic material, design complexity, and precision requirements, 3, 4, or 5-axis CNC machines are typically used to machine the parts. Plastic CNC machining is a standard industrial process that uses Computer Numerically Controlled (CNC) technology to cut plastic materials into desired shapes and dimensions. This efficient and versatile machining process provides reliable results in making plastic parts that fit the intended applications. How to process plastics with CNC machines for high quality and productivity. From the problem of material pullout, we introduce the methods to achieve perfect surface finish on plastic and the tips for CNC plastic machining.

Reading Plastic & Metal’s CNC turning machines spin plastic rods, bars, or tubes against a cutting tool to shape them into symmetrical components. This process excels in producing shafts, pins, and fittings with unmatched precision.Computerized numerical control (CNC) milling increases the accuracy and eficiency of plastic milling. When milling plastic, it is crucial to properly stabilize the part on the worktable and minimize vibrations from the high-speed cutting tool – these may result in chatter marks and decreased accuracy due to the shape wandering. Based on the CNC machining method — CNC drilling, CNC turning, or CNC milling — engineers must adhere to different guidelines to produce superior plastic CNC machined parts. In this article, we’ll break each of them down. CNC plastic machining is a technique whereby plastic cutting tools are guided by computer numerical control technology. The process, also known as CNC, involves accurate movements of tools and workpieces and predetermined computer instructions that make different plastics including parts and products.

Plastic machining factories rely on computer-controlled devices to form raw materials into designated pieces. It is this technique, known for its accuracy, which works particularly well with plastics, giving one a cheaper option of .

Learn how to select the right plastic for CNC machining. Avoid pitfalls, ensure optimal performance, and reduce costs for your CNC machined parts with our comprehensive guide.Plastic CNC machining is a subtractive manufacturing method that involves placing a solid block of plastic against a moving cutting tool that removes material from the block. In order to shape the final product, the cutting tool follows a predetermined path directed by a digital design file. CNC plastic machining utilizes a subtractive process to gradually cut a plastic block to the desired shape and precision. Depending on the plastic material, design complexity, and precision requirements, 3, 4, or 5-axis CNC machines are typically used to machine the parts. Plastic CNC machining is a standard industrial process that uses Computer Numerically Controlled (CNC) technology to cut plastic materials into desired shapes and dimensions. This efficient and versatile machining process provides reliable results in making plastic parts that fit the intended applications.

How to process plastics with CNC machines for high quality and productivity. From the problem of material pullout, we introduce the methods to achieve perfect surface finish on plastic and the tips for CNC plastic machining.Reading Plastic & Metal’s CNC turning machines spin plastic rods, bars, or tubes against a cutting tool to shape them into symmetrical components. This process excels in producing shafts, pins, and fittings with unmatched precision.

grinding for precision turned parts

Q: How do I weld sheet metal with a wire feed welder? A: Welding sheet metal requires a delicate balance of heat and speed to avoid burn-through. Use a lower power setting, adjust the wire feed speed to match, and use a series of tack .

cnc turning plastic part|cnc turning services near me