sheet metal fabrication calculation pdf Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. 3D CAD files are converted into machine code, which controls a . The choice of bullet material depends on the specific application of ammunition and preferences of the shooter. Copper is often preferred for its non-toxic nature and accuracy, lead is chosen for its affordability, and steel is used for its durability and cost-effectiveness.

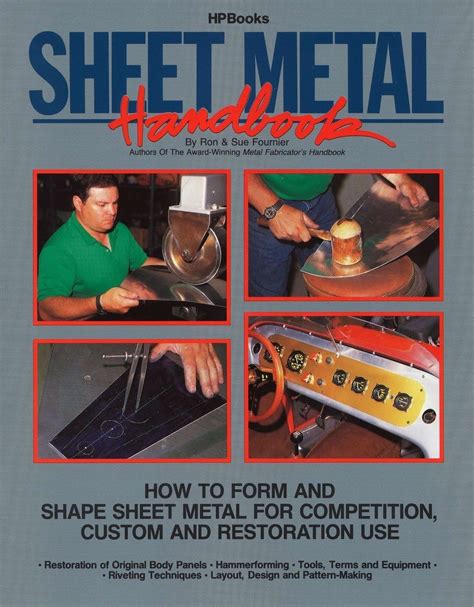

0 · sheet metal handbook free download

1 · sheet metal fabrication handbook pdf

2 · sheet metal die design pdf

3 · sheet metal design handbook pdf

4 · sheet metal design guideline pdf

5 · sheet metal design calculations pdf

6 · sheet metal calculations pdf

7 · sheet metal bending guide pdf

Ceramic or Metal Foil – This is what you see and is actually under the precious metals. The honeycomb type of pattern that you see throughout the catalytic converter. It is meant to have all of those openings and surface space in order to have .

Chapter 6.Formulas for Sheet Metal Layout and Fabrication 6.1 6.1 Sheet Metal Flat-Pattern Development and Bending / 6.8 6.2 Sheet Metal Developments,Transitions,and Angled Corner .Objectives. By the end of today you should be able to. .describe different forming processes, when they might be used, and compare their production rates, costs and environmental .

Understanding the costs of a sheet metal part will help you evaluate the choices each supplier is making to provide their price. First, let’s take a look at some of the key components of a sheet .Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. 3D CAD files are converted into machine code, which controls a .HANDBOOK OF STRUCTURAL STEELWORK. EUROCODE EDITION. First text page_Layout 1 04/10/2013 14:26 Page 1

Engineering and Mechanics. Mathematics behind Metal Fabrication. Booklet VE3: Division, Angle, Shape, Formulae, and Optimisation. YuMi Deadly Maths Past Project Resource. .Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and/ or bending. 3D CAD files are converted into machine code, which controls a .

Sheet Metal Unfold Rule Equations. Register for more free training on this topic at KETIV Virtual Academy. Free training, every week, from real experts. Register Now. Contents. Introduction .

To give users an understanding of sheet metal calculations in general and how they are used in SolidWorks, this article will review the following: The definition of both bend allowance and .Sheet metal fabricators also have these same choices. The most significant choice involves coatings such as plating or powder coating. In many cases, the cost of the equipment is simply too much given the small amount of customer requirements for the coating. In other cases, the EPA requirements or the

sheet metal handbook free download

teparay precision sheet metal

Estimating-Sheet-Metal-Fabrication-Costs-v3 19.pdf - Free download as PDF File (.pdf), Text File (.txt) or read online for free. This document discusses calculating material costs for sheet metal parts. It notes that simply multiplying the part .Sheet Metal Fabrication Cost Calculation Pdf Sheet Metal Fabrication Cost Calculation PDF Ebook Title: Mastering Sheet Metal Fabrication Cost Estimation Ebook Outline: Introduction: The Importance of Accurate Costing in Sheet Metal Fabrication Chapter 1: Material Costs: Understanding Material Pricing and Variations

Sheet Metal Fabrication Cost Calculation Pdf Sheet Metal Fabrication Cost Calculation PDF Ebook Title: Mastering Sheet Metal Fabrication Cost Estimation Ebook Outline: Introduction: The Importance of Accurate Costing in Sheet Metal Fabrication Chapter 1: Material Costs: Understanding Material Pricing and VariationsSheet Metal MODULES All of the modules listed below are included in the Trainee Guide and the Instructor’s Guide. The following ISBN and . metric system conversions, basic geometry, and calculation of stretchouts. Fabrication One – Parallel Line Development (22.5 Hours) Trainee ISBN 978-0-13-604837-4 Instructor ISBN 978-0-13-604882-4Formulas: Bend Allowance (BA) – The amount of added to the sum of the two leg lengths to obtain the flat pattern length. Bend Deduction (BD) – The amount removed from the sum of the two flange lengths to obtain a flat pattern. Material Thickness (MT) – The gauge of the material in decimal form. Bend Angle (B<) – The inside angle between the two legs or flanges of a bend.

Sheet Metal Fabrication Cost Calculation Pdf Sheet Metal Fabrication Cost Calculation PDF Ebook Title: Mastering Sheet Metal Fabrication Cost Estimation Ebook Outline: Introduction: The Importance of Accurate Costing in Sheet Metal Fabrication Chapter 1: Material Costs: Understanding Material Pricing and VariationsStep four: repeating the calculation for the different phases of the production cycle. Now that we have calculated the production cost from raw material to the output of machine 1, we can repeat the procedure for the other machines or phases that complete the production cycle.

terminal box vs junction box

Cone Layout Development by Marking and Calculation Method with Practical Example. Full Cone is a very common shape in fabrication industry as it is most frequently used shape in fabrication so it is very necessary that every fabrication engineer or professionals in fabrication field must have knowledge of Cone layout Development if you have detailed knowledge of cone .Kerf calculation: Understanding how the kerf width (material removed during cutting) impacts final part dimensions and how to compensate for it. Chapter 3: Bend Allowance Calculations: Mastering the Heart of Sheet Metal Fabrication Bend allowance is arguably the most critical calculation in sheet metal fabrication.Kerf calculation: Understanding how the kerf width (material removed during cutting) impacts final part dimensions and how to compensate for it. Chapter 3: Bend Allowance Calculations: Mastering the Heart of Sheet Metal Fabrication Bend allowance is arguably the most critical calculation in sheet metal fabrication.Sheet Metal Fabrication Calculation Pdf: The Calculation of Sheet Metal Work alfred Dickason,1966 Sheet Metal Forming R. Pearce,1991-12-31 The pressing of sheet metal into useful shapes is a technology which requires an understanding of a wide range of subjects This text is divided into three sections processes materials and tests In Part 1 .

Sheet Metal Fabrication Calculation Pdf: The Calculation of Sheet Metal Work alfred Dickason,1966 Sheet Metal Forming R. Pearce,1991-12-31 The pressing of sheet metal into useful shapes is a technology which requires an understanding of a wide range of subjects This text is divided into three sections processes materials and tests In Part 1 .Metal The Welding Fabrication Industry needs qualified welder fabricators who can deal with a . USING YOUR SCIENTIFIC CALCULATOR 12 Using your calculator 13 Using the fraction key on your calculator 14-15 Checking answers for accuracy when using your calculator 16-18

SHEET METAL FABRICATION 1. INTRODUCTION: Metal fabrication is the building of metal components and structures by cutting, bending, and assembling processes. . PROFITABILITY CALCULATIONS: Sr NoParticulars UOM Year Wise estimates Year 1 Year 2 Year 3 Year 4 Year 5 1 Capacity Utilization % 40 50 60 70 80ºõ³ .VE3: Mathematics behind metal fabrication Booklet 3: Division, angle, shape, formulae and optimisation VM1: Mathematics behind handling small boats/ships Booklet 1: Angle, distance, direction and navigation VM2: Mathematics behind handling small boats/ships Booklet 2: Rate, ratio, speed, fuel and tides

In sheet metal bending calculations, the impact of different material types on the bending factor is significant and multifaceted, influencing the accuracy, quality, and efficiency of the bending process. . My extensive experience has allowed me to become an expert in the fields of sheet metal fabrication, machining, mechanical engineering .Sheet bending Sheet bending is defined as the straining of the metal around a straight axis. During bending operation, the metal on the inner side of the neutral plane is compressed, and the metal on the outer side of the neutral plane is stretched. Bending causes no change in the thickness of the sheet metal.Kerf calculation: Understanding how the kerf width (material removed during cutting) impacts final part dimensions and how to compensate for it. Chapter 3: Bend Allowance Calculations: Mastering the Heart of Sheet Metal Fabrication Bend allowance is arguably the most critical calculation in sheet metal fabrication. These software provide sheet metal modules or related functions that can help designers with the design and unfolding calculations of sheet metal parts. Use the sheet metal module or tools in the software: Most 3D CAD software provides related tools and functions for sheet metal design. For example, Creo offers a variety of methods for .

5. • Aluminum is also a popular metal used in sheet metal due to its flexibility, light weight, and cost effectiveness • Most common Grade 3003- H14 is fairly strong, while maintaining the same formability and low cost. It is corrosion resistant and weldable. It is often used in stampings, spun and drawn parts, and fan blades • Brass is an alloy of copper, which is widely .

Sheet Metal Fabrication Calculation Pdf: The Calculation of Sheet Metal Work alfred Dickason,1966 Sheet Metal Forming R. Pearce,1991-12-31 The pressing of sheet metal into useful shapes is a technology which requires an understanding of a wide range of subjects This text is divided into three sections processes materials and tests In Part 1 .

Design and Fabrication of Sheet Rolling - Free download as Word Doc (.doc / .docx), PDF File (.pdf), Text File (.txt) or read online for free. This document provides information about the design and fabrication of a sheet rolling machine. It discusses bending of sheet metal using rollers, the process of rolling sheet metal through multiple rollers, and stresses induced on the sheet metal .

DESIGN AND FABRICATION OF SHEET ROLLING MACHINE A PROJECT REPORT . CHENNAI 600 025 BONAFIDE CERTIFICATE Certified that this project report “DESIGN AND FABRICATION OF SHEET METAL ROLLING MACHINE” is the bonafide work of “K.FEROZE ALI (950612114030), S.ABDUL RHAMAN (950612114301), V.BALA SANKAR . A sheet metal tool development results from an ingenious use of a large number of manufacturing technologies, both using state-of-the-art automated processes and long-established metalwork, often .

sheet metal fabrication handbook pdf

temperature inside a powder coated steel box

$35.20

sheet metal fabrication calculation pdf|sheet metal calculations pdf