sheet metal maximum thickness in mm Ga. is different from inches, there is no conversion formula. Even when the non .

I'm going to replace the rusted-out bedfloor on my truck soon in shop, and I need to order some sheetmetal. What gauge should I go with? I won't have the ribs working for me like the factory floor, so I'm torn as to what thickness to use for durability.

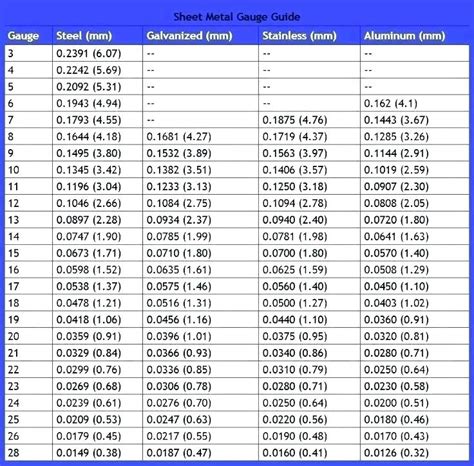

0 · steel sheet sizes in mm

1 · standard sheet metal thickness mm

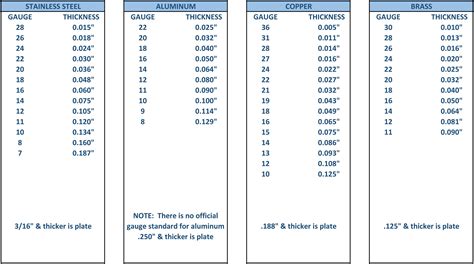

2 · stainless steel sheet thickness chart

3 · sheet metal weights chart

4 · sheet metal thickness chart printable

5 · metal sheet thickness chart

6 · metal sheet size chart

7 · metal plate gauge thickness chart

The 7 Hole Distribution Box includes the following ; 7 - S-35 Seal (yellow) for thin-wall 4 ; 2 - P-10 Plug (orange) for unused holes ; Injection molded HDPE Distribution box accepts Tuf-Tite's Box Fittings and Speed-Levelers › See more product details

Standard sheet metal thickness and size varies across different metals. Find standard sheet metal gauges and mm measurements in this article. See moreIn Australia, the typical thickness of sheet metal is between 0.5 millimetres and 6 millimetres. Anything thicker 6 millimetres is classified as metal plate, and anything thinner than 0.5 . See moreIn the fabrication industry, ‘gauge’ is an identifier for the standard thickness of sheet metal of a specific material. The gauge size is based on the weight of the metal sheet and is inversely proportional to the thickness, which means the higher it is, the thinner the . See moreThere are two ways to measure sheet metal: using a measuring tape (which is less precise) and a gauge wheel (more typically used in the industry). See more

Yes, sheet metal thickness is important as it determines what kind of fabrication processes can be used. Thinner sheet metal is suitable for different processes and different . See more Ga. is different from inches, there is no conversion formula. Even when the non .

The chart below can be used to determine the equivalent sheet thickness, in inches .Sheet Metal Material Thickness Range. Because sheet metal parts are manufactured from a single sheet of metal, the part must maintain uniform wall thickness. Sheet metal thickness .

Keeping a gauge conversion chart nearby is an easy way to determine the actual thickness of a sheet of metal in inches or millimeters. For . Material Thickness (T): The uniform thickness of the sheet metal workpiece, typically measured in millimeters or inches. Inside Radius (R): The radius of the bend measured from the inside surface of the material, usually . Sheet metal is simply any piece of metal with a width ranging between 0.5 and 6mm. This width is what defines sheet metal thickness. Any piece exceeding 6mm is known as .

The thickness of sheet metal starts from 0.5 mm and goes up to 6 mm. Anything above that is a metal plate. The thin sheet metal is easy to form, while still providing great strength. At a relatively cheap price, it makes a great .Max. file size: 60 MB. Sheet Metal Gauge Chart: Full Size Range from 0/7 SWG to 50 SWG - Conversions to mm's and Inches. (1 thou to 1/2 inch) - (0.3mm to 12.7mm)i.Because parts are formed from a single sheet of metal, designs must maintain a uniform thickness. Factors like bend radius and feature-to-feature cut distances should be considered. .

Sheet metal thickness is an important factor in fabrication. Metal fabrication shops often work with raw stock sheet metal from 0.02” to 0.250” thick. What does that mean for you, the customer?Opening(mm) Center type(mm) Thickness of sheet(mm) min. Max : Size(mm) Stainless Steel : Iron: . Many perforated metal goes for decoration or flooring sheet. The raw material processed by the machine: Stainless steel plate, aluminum, cold and hot steel, copper plate and fiber sheet, plastic sheet and so on.

Sheet Metal Gauge Chart: Full Size Range from 0/7 SWG to 50 SWG - Conversions to mm's and Inches. (1 thou to 1/2 inch) - (0.3mm to 12.7mm)i. . We also provide zinc sheets in sizes up to 3000mm x 1100mm and the standard metric 8ft x 4ft, with a maximum thickness of 1.5mm.

Uncover the basics of sheet metal tolerances, including measurement methods and industry standards for perfect parts. . Material Thickness (mm) Tolerance Range (mm) 0.5 -1.0: ±0.1: 1.0 - 2.0: ±0.15: 2.0 -3.0: ±0.2 . Dimension tolerance refers to the allowable variation in size and is expressed as the difference between the maximum limit . In this same example, the marginal thinning strain is -16.5 percent. Reducing the starting thickness of 0.8 mm by 16.5 percent results in a sheet 0.668 mm thick. So, any areas in plane strain on the formed part measuring 0.668 mm or thicker can be considered safe in .Upto and including 2 mm. Max thickness of sheet metal. Personally, I have worked with 4 inch material on a rare occasion, however I work with 1mm (approx. 0.04 in) up to 50.8mm (approx. 2 in .

steel sheet sizes in mm

Sheet metal thickness (T) = 1 mm; . Mathematically, K-factor = d / t, where: d = distance from inside bend surface to neutral layer t = total material thickness. Maximum K-Factor Value. The neutral layer’s position is constrained by the physical boundaries of the material. At its theoretical maximum, the neutral layer could be located at .

The bend’s outer edge would crack if it exceeds the minimum bend radius which is typically specified according to the metal sheet thickness (t) like 1t, 2t, 3t etc. . 1–6 mm: 1 time the thickness of the sheet: 6–12 mm: 1.5 times the thickness of the sheet: 12–25 mm:Study with Quizlet and memorize flashcards containing terms like 1. Sheet metalworking includes both forming and cutting operations: (a) True or (b) false?, 2. Typical sheet-metal thicknesses are between 0.4 mm (1/64 in) and 6 mm (1/4 in). When thickness exceeds the upper limit of this range, the stock is usually referred to as which one of the following: (a) bulk stock, (b) . The maximum drawing force ‘Fdmax’ needed to form a round cup can be expressed by the empirical relation given by the equation 6 which is ‘Fdmax = n x pi x d x t x su’, where ‘su’ is the tensile strength of the blank material (in megapascal, MPa), ‘d’ is the punch diameter (in millimetres, mm), ‘t’ is the sheet thickness (mm .

Question: Question 2(40%)Figure Q2: A sheet metal produced by a rolling millFigure Q2 illustrates the production record of sheet metal produced by a rolling mill. The sheet has a nominal thickness of 1 mm , with a specification of 1.00+-0.05mm. A quality inspector measures a sample of five sheets at the end of each day.

$\begingroup$ I think so too, wasn't reading too carefully. Reason is you might get away with less with a sheet metal screw, like a single thread pitch. With machine screws, think in terms of number of threads. 6 is rule of thumb for getting full strength, 3-4 would be the bare minimum, but factor into this that the ends of the hole aren't perfect, so the actual thickness .Question: Sections 3.1 through 3.7 3.1 A rectangular sheet metal of 5 mm thickness is bent into a circular cylinder having radius r. Calculate the diameter of the cylinder and the maximum moment developed in the metal if the allowable stress is not to exceed 96MPa,E=70GPa, and ν=0.3. 3.2 A 20-mm-wide and 0.5-mm-thick steel band saw ( E=210GPa,ν=0.3 ) runs over two Introduction. Welding is a primary process in sheet metal fabrication, characterized by high labor intensity and harsh working conditions.As such, high proficiency is essential. Automation in welding and the development of innovative joining methods have been consistent focal points for professionals in welding technology.. A pivotal aspect of welding automation is .3.1 A rectangular sheet metal of 5 mm thickness is bent into a circular cyl- inder having radius r. Calculate the diameter of the cylinder and the maximum moment developed in the metal if the allowable stress is not to exceed 96 MPa, E= 70 GPa, and v=0.3.

VEVOR Rolling Mill, 2.95"/75 mm Jewelry Rolling Mill Machine, 1: 2 Gear Ratio, 3-in-1 Multi-Function Rolling Mill, 0.03-6.5mm Press Thickness for Metal Jewelry Making Sheet Square Wire Semicircle Visit the VEVOR Store What is Stainless Steel Sheet Metal Thickness? Definition and Importance; Stainless steel sheet metal thickness refers to the distance between the two surfaces of the sheet. This measurement is critical because it directly .

R – bending radius of the workpiece, mm; t – steel plate thickness, mm; r 1 – radius of upper and lower roller shafts, mm; R’- R+t, mm; L 2 – side roll center distance, mm; Due to the springback of sheet metal, the value of H obtained in the above formula needs to be corrected properly in practical application. b. Roll bending of .

Sheet Metal Operation. Question Download Solution PDF. Find the blanking force required to punch 10 mm diameter holes in a steel sheet of 3 mm thickness. Given shear strength of material = 400 MPa, penetration = 40% and shear provided on the punch = 2 mm. . The maximum value of reduction in rolling process is Where 'D' is roll diameter and .The capacity or ‘tonnage’ of a brake press refers to the maximum amount of force it can exert. The material thickness, type and bend radius dictate how many tons of force are needed when fabricating a part. . Note that the term ‘sheet metal’ is typically used to refer to materials that are under 3mm in thickness. Sheet metal bending .

standard sheet metal thickness mm

Sheet Metal Guillotine - 800 mm cut length - incl. base frame. The sheet metal guillotine MSW-HS800 from MSW is a precise and easy-to-use multi-purpose shear for all types of sheet metal and plastic. Thanks to the elongated handle and the maximum leverage it creates, the shear cuts through up to 1.5 mm-thick sheet materials like butter.

To see how we start to process the ferrous and non-ferrous sheet metal materials please take a look at our web page on CNC punching, Trumpf 200/3000 CNC punching and Trumpf 3030 fibre laser cutting Sheet metal thickness tolerances for Austenitic, Ferritic and . A sheet of metal is 29.4 mm wide and 16.1 mm long. If it weighs 4.093 g and the density of the metal is 7.23 g/cm3, what is the thickness of the sheet (in mm)? . Find the value of x such that the volume is a maximum. barnsey471; Mar 20, 2017; Calculus; Replies 6 Views 5K. Calculus Mar 20, 2017. JeffM. J. E. 4 Precision Sheet Metal Size FAQ. 4.0.1 What factors should I consider when choosing the right sheet metal gauge for my project? 4.0.2 How can I ensure I'm using the right material thickness for my sheet metal project? 4.0.3 Can you share a real-life example of how choosing the right sheet metal gauge made a significant difference in a project?

The most common thickness of spun materials falls between 0.6 mm and 1.3 mm. Specialized facilities can spin metal from a minimum of about 0.1 mm to approximately 120 mm. Maximum thickness is limited only technically by the size of machining equipment and available power. The cutting speed and thickness capabilities of a laser cutter depend on several factors, including the laser power, type of metal, and material thickness. This article provides a comprehensive laser cutting thickness and speed chart for lasers ranging from 500W to 30kW, covering mild steel, stainless steel, and aluminum. Key TakeawaysLooking for WOODWARD FAB, US Sheet Metal, Sheet Metal Thickness Gauge? Find it at Grainger.com®. With over one million products and 24/7 customer service we have supplies and solutions for every industry. . Maximum Measurement - Inch 0.3120 in. Maximum Measurement - Gauge #0. Minimum Measurement - Inch 0.012 in. Minimum Measurement - Gauge .

Are you in need of curved metal? At Albina Co., Inc. we have mastered the skills of steel and metal bending, rolling and fabrication. We bend and roll structural steel members, various sizes of round pipe and HSS material, and plate. We work with .

sheet metal maximum thickness in mm|standard sheet metal thickness mm