class 1 division 2 electrical enclosures Electrical and electronic equipment used in Class I, Division 2 locations must meet rigorous standards to ensure safety. NEC 500 and UL121201 highlights several protection techniques, including: Non-incendive Equipment: Designed . Buy wholesale metallic denim fabric for this season's clothing at Alibaba.com. International wholesalers providing your business with denim fabric and much more.

0 · class 2 div 1 enclosure

1 · class 1 division 2 requirements

2 · class 1 division 2 locations

3 · class 1 div 2 wiring

4 · class 1 div 2 specifications

5 · class 1 div 2 rules

6 · class 1 div 2 receptacle

7 · class 1 div 2 code

eMachineShop offers cost-effective sheet metal and sheet plastic fabrication services whether you need a single part, batch of prototypes, or full production order. 50+ Materials. FREE Shipping in the USA. 100% Quality Guaranteed. Waterjets mainly cut sheet material into 2D parts using a high-pressure stream of water and abrasive.

class 2 div 1 enclosure

can you cut sheet metal with scissors

class 1 division 2 requirements

The National Electrical Code (NEC) provides comprehensive guidance on electrical requirements for Class 1 Division 2 (C1D2) locations. The guidance revolves around material groups, surface temperature and .Rely on nVent HOFFMAN to protect your electrical controls in Division 1 or Zone 1 areas with flameproof and explosion proof enclosures. Our enclosures also improve the reliability of .A Class I, Division 1 or Division 2 location may be reclassified as a Class I, Zone 0, Zone 1, or Zone 2 location only if all of the space that is classified because of a single flammable gas or vapor source is reclassified.

EJB enclosures are globally certified for use in worldwide applications. They are listed for Class I, Division 1 and Class II, Division 1 hazardous areas, and they also have IECEx and ATEX .Electrical and electronic equipment used in Class I, Division 2 locations must meet rigorous standards to ensure safety. NEC 500 and UL121201 highlights several protection techniques, including: Non-incendive Equipment: Designed .Regulatory bodies like the Occupational Safety and Health Administration (OSHA) have established systems that classify locations which exhibit potentially dangerous conditions to .

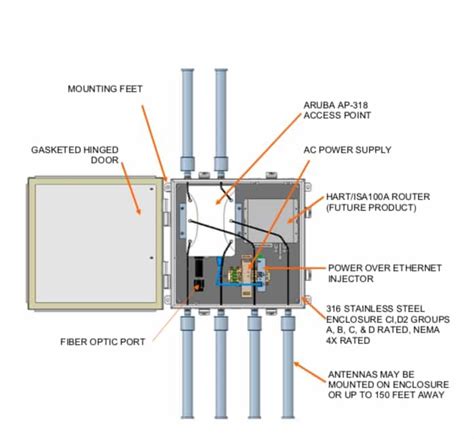

Class 1 Division 2 (C1D2) enclosures are designed to house electrical equipment in hazardous locations. These locations are areas where flammable gases, vapors, or dust may be present in the air in quantities . NEMA 1. General-purpose and for indoor use. Type 1 provides a degree of protection to the equipment inside the enclosure against the ingress of solid foreign objects, .

can you install electrical single gang box back to back

.00.28.40Ingress Protection (IP) codes for electrical enclosures in Class 1/DIV 2 and non-hazardous locations. An IP (Ingress Protection) rating is used mainly by buyers in Europe to specify the .

We recommend electrical enclosures meet or exceed a NEMA rating of Type 4 or Type 4X for use in a Class1 Div2 hazardous location when used with appropriate purge systems. The National Electrical Code (NEC) provides comprehensive guidance on electrical requirements for Class 1 Division 2 (C1D2) locations. The guidance revolves around material groups, surface temperature and protection techniques against any risks.Rely on nVent HOFFMAN to protect your electrical controls in Division 1 or Zone 1 areas with flameproof and explosion proof enclosures. Our enclosures also improve the reliability of panels in hazardous locations with purge and pressurization solutions.

A Class I, Division 1 or Division 2 location may be reclassified as a Class I, Zone 0, Zone 1, or Zone 2 location only if all of the space that is classified because of a single flammable gas or vapor source is reclassified.

EJB enclosures are globally certified for use in worldwide applications. They are listed for Class I, Division 1 and Class II, Division 1 hazardous areas, and they also have IECEx and ATEX certifications.

Electrical and electronic equipment used in Class I, Division 2 locations must meet rigorous standards to ensure safety. NEC 500 and UL121201 highlights several protection techniques, including: Non-incendive Equipment: Designed to prevent ignition under normal operating conditions without requiring an explosion-proof enclosure.

Regulatory bodies like the Occupational Safety and Health Administration (OSHA) have established systems that classify locations which exhibit potentially dangerous conditions to the degree of hazard presented.

Class 1 Division 2 (C1D2) enclosures are designed to house electrical equipment in hazardous locations. These locations are areas where flammable gases, vapors, or dust may be present in the air in quantities sufficient to produce explosive or ignitable mixtures. NEMA 1. General-purpose and for indoor use. Type 1 provides a degree of protection to the equipment inside the enclosure against the ingress of solid foreign objects, primarily dirt. They also prevent contact with live parts. NEMA 2. Drip-tight and for indoor use.Ingress Protection (IP) codes for electrical enclosures in Class 1/DIV 2 and non-hazardous locations. An IP (Ingress Protection) rating is used mainly by buyers in Europe to specify the extent of protection an electrical enclosure has against environmental conditions. We recommend electrical enclosures meet or exceed a NEMA rating of Type 4 or Type 4X for use in a Class1 Div2 hazardous location when used with appropriate purge systems.

The National Electrical Code (NEC) provides comprehensive guidance on electrical requirements for Class 1 Division 2 (C1D2) locations. The guidance revolves around material groups, surface temperature and protection techniques against any risks.

Rely on nVent HOFFMAN to protect your electrical controls in Division 1 or Zone 1 areas with flameproof and explosion proof enclosures. Our enclosures also improve the reliability of panels in hazardous locations with purge and pressurization solutions.A Class I, Division 1 or Division 2 location may be reclassified as a Class I, Zone 0, Zone 1, or Zone 2 location only if all of the space that is classified because of a single flammable gas or vapor source is reclassified.EJB enclosures are globally certified for use in worldwide applications. They are listed for Class I, Division 1 and Class II, Division 1 hazardous areas, and they also have IECEx and ATEX certifications.

Electrical and electronic equipment used in Class I, Division 2 locations must meet rigorous standards to ensure safety. NEC 500 and UL121201 highlights several protection techniques, including: Non-incendive Equipment: Designed to prevent ignition under normal operating conditions without requiring an explosion-proof enclosure.Regulatory bodies like the Occupational Safety and Health Administration (OSHA) have established systems that classify locations which exhibit potentially dangerous conditions to the degree of hazard presented.

Class 1 Division 2 (C1D2) enclosures are designed to house electrical equipment in hazardous locations. These locations are areas where flammable gases, vapors, or dust may be present in the air in quantities sufficient to produce explosive or ignitable mixtures.

NEMA 1. General-purpose and for indoor use. Type 1 provides a degree of protection to the equipment inside the enclosure against the ingress of solid foreign objects, primarily dirt. They also prevent contact with live parts. NEMA 2. Drip-tight and for indoor use.

Explore the world of electrical junction boxes – their crucial role, types, installation tips, and safety measures. Uncover the power of junction boxes in securing your electrical system.There are variety of electrical enclosures and boxes such as device boxes, mud/ENT boxes, underground pull boxes, explosionproof boxes and accessories. These enclosures and boxes .

class 1 division 2 electrical enclosures|class 1 div 2 specifications