classification of edm cnc wire cut machine A wire-cut EDM machine using the CNC drawing plotter and optical line follower techniques was produced in 1974. Dulebohn later used the same plotter CNC program to directly control the EDM machine, and the first CNC EDM machine . Trane® offers an array of space and energy-saving fan-powered options to suit the space that needs optimal heating and cooling. VariTrane™ variable-air-volume units (VAV) are among the industry leaders in quality and reliability and are designed to .Single Duct terminals are the fundamental building blocks for Variable Air Volume (VAV) systems. Their primary function is to regulate airflow to a zone, in response to zone temperature requirements. The Titus ESV is unique as it incorporates many design features that increase .

0 · wire edm vs saw cutting

1 · wire edm surface finish

2 · wire edm explained

3 · what is wire edm machining

4 · what is wire edm cutting

5 · nota cnc edm wire cut

6 · how does edm cutting work

7 · best wire cut edm machine

Vandal Resistant Pull Box Inserts are a simple and effective tool for discouraging copper theft; providing safety and security to the most common pull box types and sizes.StrongBox manufactures the finest metal enclosures available for protecting electrical controls, power meters, pumps, backflow prevention devices, and more. We also provide a quality line .

wire edm vs saw cutting

According to different cutting methods and functions, EDM wire cut machines can be divided into many types. This article will introduce the classification of EDM wire cut machines in detail. 1. Classification according to working principle. The wire EDM machine uses the . There are two primary types of EDM, wire and sinker EDM, sometimes called ram EDM. However, our focus will be on the wire EDM machine and the wire-cut EDM process. Each EDM works differently, so here is a brief .

how do sheet metal screws work

Wire cutting electrical discharge machining, commonly referred to as wire cut EDM, uses a wire as the “cutter” and erodes material by sparking between wire and workpiece. The wire electrode discharges along the whole .Different Types of EDM Technology Wire EDM. Wire electrical discharge machining (WEDM) employs a thin metallic wire, typically brass or copper, ranging from 0.02 to 0.3mm in .A wire-cut EDM machine using the CNC drawing plotter and optical line follower techniques was produced in 1974. Dulebohn later used the same plotter CNC program to directly control the EDM machine, and the first CNC EDM machine .

According to different wire feed speed, there are two different type wire EDM machine in the market, CNC low speed feed wire cut EDM machine and CNC high speed feed wire cut EDM machine, this classification method is .This review paper involves wire cut EDM optimization parameters. Pulse interval, pulse duration, wire feed, voltage, and mean current are the operational parameters.

Your EDM-wire cut machine cuts the material by continuous spark discharges between the moving wire and the work-piece surface; the sparks happen in a square waveform and the spark-on and spark-off time is . Wire EDM machining is a kind of technological method of spark discharge cutting and forming the machined workpiece for the metal electrode wire that is damaged in the machining area. This kind of mobile electrode wire . According to different cutting methods and functions, EDM wire cut machines can be divided into many types. This article will introduce the classification of EDM wire cut machines in detail. 1. Classification according to working principle. The wire EDM machine uses the principle of spark corrosion to cut.

There are two primary types of EDM, wire and sinker EDM, sometimes called ram EDM. However, our focus will be on the wire EDM machine and the wire-cut EDM process. Each EDM works differently, so here is a brief look at both . Wire cutting electrical discharge machining, commonly referred to as wire cut EDM, uses a wire as the “cutter” and erodes material by sparking between wire and workpiece. The wire electrode discharges along the whole length of a cut and .Different Types of EDM Technology Wire EDM. Wire electrical discharge machining (WEDM) employs a thin metallic wire, typically brass or copper, ranging from 0.02 to 0.3mm in diameter. The wire acts as a continuously moving electrode, . Wire EDM machining employs a continuously-fed wire electrode for 2D cutting. It is used for cutting pre-hardened materials. Learn more about this technology and how it is used in manufacturing.

A wire-cut EDM machine using the CNC drawing plotter and optical line follower techniques was produced in 1974. Dulebohn later used the same plotter CNC program to directly control the EDM machine, and the first CNC EDM machine was produced in 1976. According to different wire feed speed, there are two different type wire EDM machine in the market, CNC low speed feed wire cut EDM machine and CNC high speed feed wire cut EDM machine, this classification method is widely accepted in the market.This review paper involves wire cut EDM optimization parameters. Pulse interval, pulse duration, wire feed, voltage, and mean current are the operational parameters. Your EDM-wire cut machine cuts the material by continuous spark discharges between the moving wire and the work-piece surface; the sparks happen in a square waveform and the spark-on and spark-off time is controlled by the CNC.

Wire EDM machining is a kind of technological method of spark discharge cutting and forming the machined workpiece for the metal electrode wire that is damaged in the machining area. This kind of mobile electrode wire avoids the influence of electrode loss on machining accuracy. According to different cutting methods and functions, EDM wire cut machines can be divided into many types. This article will introduce the classification of EDM wire cut machines in detail. 1. Classification according to working principle. The wire EDM machine uses the principle of spark corrosion to cut. There are two primary types of EDM, wire and sinker EDM, sometimes called ram EDM. However, our focus will be on the wire EDM machine and the wire-cut EDM process. Each EDM works differently, so here is a brief look at both .

Wire cutting electrical discharge machining, commonly referred to as wire cut EDM, uses a wire as the “cutter” and erodes material by sparking between wire and workpiece. The wire electrode discharges along the whole length of a cut and .Different Types of EDM Technology Wire EDM. Wire electrical discharge machining (WEDM) employs a thin metallic wire, typically brass or copper, ranging from 0.02 to 0.3mm in diameter. The wire acts as a continuously moving electrode, . Wire EDM machining employs a continuously-fed wire electrode for 2D cutting. It is used for cutting pre-hardened materials. Learn more about this technology and how it is used in manufacturing.A wire-cut EDM machine using the CNC drawing plotter and optical line follower techniques was produced in 1974. Dulebohn later used the same plotter CNC program to directly control the EDM machine, and the first CNC EDM machine was produced in 1976.

According to different wire feed speed, there are two different type wire EDM machine in the market, CNC low speed feed wire cut EDM machine and CNC high speed feed wire cut EDM machine, this classification method is widely accepted in the market.This review paper involves wire cut EDM optimization parameters. Pulse interval, pulse duration, wire feed, voltage, and mean current are the operational parameters. Your EDM-wire cut machine cuts the material by continuous spark discharges between the moving wire and the work-piece surface; the sparks happen in a square waveform and the spark-on and spark-off time is controlled by the CNC.

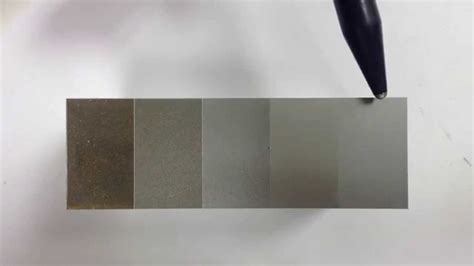

wire edm surface finish

wire edm explained

how do you remove blinds from metal brackets

what is wire edm machining

If someone fired a valyrian steel bolt at, say, The Mountain while encased in a full suit of valyrian steel playe armour, thick layered, would it pierce and kill him?

classification of edm cnc wire cut machine|nota cnc edm wire cut