part program cnc CNC Part Programming: A Fundamental Skill for Turning Operations. When it comes to CNC machining, one of the essential skills to master is part programming for turning operations. This process involves creating a set of instructions that tell the CNC machine how to precisely shape and form a workpiece on a lathe. A well-written part program is .

How we can reading an input (PMC) in CNC program? to use an input for a condition in CNC program. I want to insert a condition in my program if an input for example X0.1 is on the program call a subprogram otherwise continue the lines.

0 · what is a part program

1 · part programming for cnc machines

2 · cnc milling programming for beginners

3 · cnc machine programming and operation

4 · cnc lathe programming for beginners

5 · cnc lathe machine program

6 · basic cnc programming for freshers

7 · basic cnc programming for beginners

Mathematically k factor value is equal to the ratio of position of the neutral axis and sheet thickness. In this article, we will discuss sheetmetal bend deduction, bend allowance, K-factor, Y-factor, and sheet metal flat pattern calculations.

what is a part program

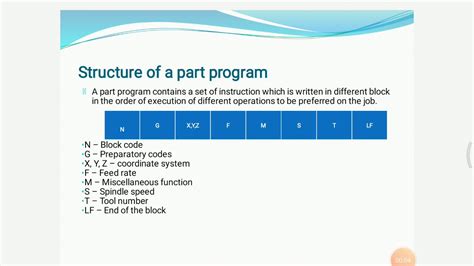

Learn about CNC programming and improve your skills with CNCCookbook's articles, tips, and resources for beginners and experienced .The part program is a sequence of instruction that describe the work that is to be done to a part. Typically these instructions are generated in Computer-aided manufacturing software and are then fed into the computer numerical control (CNC) software on the machines, such as drills, lathes, mills, grinders, routers, that are performing work on the part. The CNC computer then translates the set of instructions into a standardized format of G-code and M-code commands and follow the instru.

1. UNIT 5 CNC MACHINE – Numerical Control (NC) machine tools – CNC types, constructional details, special features, machining centre, part programming fundamentals CNC – manual part programming–micromachining .

cnc machined valve factories

7. CNC PROGRAMMING CNC is the part program is a set of encoding information, giving co-ordinates and other details to indicate how a tool should move in a relation to a work piece in a machine should perform . Manual programming for a CNC mill or lathe has been the most common way to program over the years that CNC machines have been used. Manual programming is done either by hand and transferred to a computer file, or punched in by hand on the machine controller.ProsLets look at the good stuff first. Manual programming is limitless when it .CNC Part Programming: A Fundamental Skill for Turning Operations. When it comes to CNC machining, one of the essential skills to master is part programming for turning operations. This process involves creating a set of instructions that tell the CNC machine how to precisely shape and form a workpiece on a lathe. A well-written part program is .Conversational Programming Tool - Manual Guide i. Conversational programming to simplify part program creation. MANUAL GUIDE i makes it quick and easy to program FANUC CNCs for turning, milling and compound machining. Self-explanatory menus and 3D graphic simulations guide the user through the programming, producing highly efficient results even for complex .

Easel is developed by Inventables, makers of the popular X Carve CNC routers, and is a free all-in-one CNC software. There is also a paid version (Easel Pro) that has some extra features. If Easel suits your purposes, you will have CAD software, CAM software, simulator software, and control software all in one place – ideal for beginners or .A CNC program is composed of a series of sequential instructions related to the machining of a part. Each instruction is specified in a format the CNC system can accept, interpret and process. Each instruction must also conform to the machine tool specifications.

Probing in part program example Renishaw. Thread starter Dukerc51; Start date Mar 31, 2022; Replies 11 Views 7,181 D. Dukerc51 Aluminum. Joined Jun 24, 2011 Location Maine. Mar 31, 2022 #1 So I have a new Kitamura with the Arumatik control and a Renishaw probing package. . CNC Machining. ABOUT PRACTICAL MACHINIST. CNC | CNC part program, CNC programming | Introduction of part program | G code | M code #lecture 2In this video you will learn about part program which is u.

5. The part program includes, in addition to the lines of CNC code, comments in English which explain what is being done in the part program. A user not specially expert in part programming can then read and understand the documented part program (see Figure 4). 6. The part program is presented on a graphic simulator for editing and approval.9. In _____ the operator directly feeds part geometry data and commands into the machine control unit before performing operations on the job. a) Manual part programming b) Computer-assisted part programming c) Manual data input d) Cad/cam part programming View Answerabove the surface of the part. m03 start spindle rotation clockwise dirn. z-1.000, f5 the drill will advance 1.000 inch into the w/p at a feed rate of 5in./min. the drill will rapid out of the hole back to gage height (0.100 inch above work). example nc part programming. 13Powerful online GCode Viewer to simulate GCode files. NC Viewer is the best free gcode editor for verifying CNC and 3D printer files.

CNC part program. Before running a CNC program the operator should _____. Home the axes. M-codes are NOT _____. Used to set the mode of operation. CNC program moves are contained in the _____ block. Toolpath. In basic CNC program development, which part do most programmers write first?Prepare a CNC part program to machine it on any turning center using the ISO standard G-codes. You may decide the program zero to be used for the component. Write the program using the initial tool position. The work material may be taken as mild steel. 15 32.5 53.5 Ø18 R1.5 Ø45 Ø23 Figure 8.1 : Part Drawing for the Programming Example 8.1 .

Deliverable: A G-Code Part Program created using Conversational CNC. Conversational CNC is programming g-code by asking questions of the programmer in order to create operations that are similar to the operations a .

The coded instructions are composed of letters, numbers and symbols. Program input device: The program input device is the means for part program to be entered into the CNC control. Three commonly used program .

This introductory chapter to the CNC Programming Techniques presents the most basic technique of all how to develop a part program in an organized way. Its purpose is to present an engineering drawing, evaluate it and develop all procedures required to write the final program. In . Best CNC Simulator Software – Full Round-Up. Free: CAMotics – Powerful yet user-friendly free CNC simulator; NC Viewer – Free CNC simulator that can be embedded into Fusion 360; Paid: CNCSimulator Pro – All-in-one solution with CAD & CAM capabilities; G-Wizard Editor – Simple and Intuivie G-code Simulator; Eureka G-Code – Advanced CNC program .CNC G-codes & M Codes for milling and turning with explanations, syntax and program examples. . G-code is the common name for the most widely used CNC programming language. It was developed in the 1950s at MIT. . Geometry; hence, the G-Code commands are responsible for the movements of the machine that create the geometry of the part.CNC programming refers to the process of creating instructions or code that is used to control computer numerical control (CNC) machines. CNC machines are automated manufacturing tools that perform precise and complex operations on various materials, such as cutting, milling, and drilling. CNC programming involves writing a series of commands, typically in the form of a .

Part program . The part program refers to the section of a program which contains all the info needed for executing the cutting process carried out by a single cutting tool. The phrase ‘Part Program’ is sometimes also used to reference the complete program that is used to program a part. Below is an example of a part program that taps 3 holes. chess pieces program of cnc lathe . - Download as a PDF or view online for free. Submit Search. chess pieces program of cnc lathe . . G00 X25.0 Z5.0; G71 U1.0 R2.0; // MULTIPLE TURNING CYCLE FOR ROUGH TURNING// PART PROGRAM FOR QUEEN VIRTUAL PROTOTYPE .Study with Quizlet and memorize flashcards containing terms like CNC program moves are contained in the _____ block., G-codes are _____., What portion of the part program follows the toolpath blocks? and more.

CNC Drilling [Hindi] | Drilling Operation on CNC Machine, Part Program for CNC Drilling CNC MillingIn this video you will learn about CNC Milling operation a.Study with Quizlet and memorize flashcards containing terms like 1.What is a part program? A part program is a(n):, 2.What does a coordinate code communicate to a CNC machine?, 3.What is computer-aided manufacturing? and more.

Computer Numerical Control (CNC) is a method of automating control of machine tools through the use of software embedded in a microcomputer attached to the tool.With CNC, each object to be manufactured gets a custom computer program, usually written in an international standard language called G-code, stored in and executed by the machine control unit(MCU).The .

cnc machined stainless chassis guard-front

Oil canning is something you see when a metal panel appears wavy or distorted. Oil canning is an inherent characteristic of cold-rolled flat metal panels and isn’t cause for rejection but it can be an aesthetic concern in some cases.

part program cnc|what is a part program