17-4ph sheet metal $180.00 CNC, or Computer Numerical Control, machines utilize computerized programming to automate the movement of tools and machinery, enhancing precision and efficiency in manufacturing. .

0 · grade 17 4 ph meaning

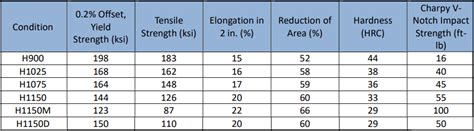

1 · 17 4ph mechanical properties

2 · 17 4 ph stainless steel material properties

3 · 17 4 ph stainless steel data sheet

4 · 17 4 ph material specification

5 · 17 4 ph equivalent material

6 · 17 4 ph conditions

7 · 17 4 material spec

In this article, we explore two types of shelf bracket s: decorative frame supports and corner shelf bracket s. Ornamental shelf bracket s add elegance and sophistication to your shelves, serving as both functional supports and decorative accents.

Shop 17 4 Stainless Steel Sheet/Plate for aerospace and thermal applications. Meets ASTM F899 and available in full size and custom cut at OnlineMetals.com. UPS Rate Increases on Long .17-4 stainless has high tensile strength and hardness and excellent corrosion .4.750.00

6.009.46.302.90

grade 17 4 ph meaning

17-4 is a precipitation-hardened chromium-nickel alloy. Excellent corrosion resistance, physical properties, and strength. Most common of the PH alloys, and considered to have the best .17-4 PH steel (AMS 5604) is a grade of martensitic, precipitation-hardening stainless steel with the additions of chromium, nickel, and copper. 17-4 stainless steel has a valuable combination of high strength, good corrosion resistance, .Sheet. Strip. Hardness. Rockwell C28. Rockwell C30. Rockwell C35. Rockwell C40. Rockwell C42. Rockwell C45. Not Rated. Tolerance Rating. Oversized. Undersized. Standard. Tight. . 17-4 stainless has high tensile strength and hardness and excellent corrosion resistance up to high temperatures. It is typically used in gate valves, chemical processing equipment, .

5.82.202.75

5.59,192.84The 17-4 stainless steel grade is an age-hardening martensitic alloy that combines high corrosion resistance and strength. Unlike conventional martensitic steels, it weldable by all standard .

17-4PH is a martensitic, precipitation-hardening stainless steel that provides an outstanding combination of high strength and hardness along with excellent corrosion resistance.17-4 Stainless Steel is a highly versatile and widely used precipitation-hardening alloy used in a number of aerospace, nuclear energy and chemical processing applications.

17 4ph mechanical properties

Stainless Steel Grade 17-4PH, also known as 17-4 Precipitation Hardening, UNS S17400, or AISI 630, is a martensitic precipitation-hardening stainless steel. It has a metallic silver-grey .

17-4PH Stainless Steel Sheet is renowned for its remarkable blend of properties that make it an ideal choice for various applications across industries. This precipitation-hardening stainless .

Shop 17 4 Stainless Steel Sheet/Plate for aerospace and thermal applications. Meets ASTM F899 and available in full size and custom cut at OnlineMetals.com. UPS Rate Increases on Long Lengths!17-4 is a precipitation-hardened chromium-nickel alloy. Excellent corrosion resistance, physical properties, and strength. Most common of the PH alloys, and considered to have the best weldabilty.17-4 PH steel (AMS 5604) is a grade of martensitic, precipitation-hardening stainless steel with the additions of chromium, nickel, and copper. 17-4 stainless steel has a valuable combination of high strength, good corrosion resistance, and toughness in both base metals and welds.Sheet. Strip. Hardness. Rockwell C28. Rockwell C30. Rockwell C35. Rockwell C40. Rockwell C42. Rockwell C45. Not Rated. Tolerance Rating. Oversized. Undersized. Standard. Tight. Yield Strength. . Also known as Project 70+, this material machines faster with less wear on cutting tools than standard 17-4 PH stainless steel. Shim Stock. Shim Stock.

17-4 stainless has high tensile strength and hardness and excellent corrosion resistance up to high temperatures. It is typically used in gate valves, chemical processing equipment, pump shafts, gears, ball bearings, bushings, and fasteners.

The 17-4 stainless steel grade is an age-hardening martensitic alloy that combines high corrosion resistance and strength. Unlike conventional martensitic steels, it weldable by all standard methods, and achieves hardening with simple low-temperature treatment over a .17-4PH is a martensitic, precipitation-hardening stainless steel that provides an outstanding combination of high strength and hardness along with excellent corrosion resistance.17-4 Stainless Steel is a highly versatile and widely used precipitation-hardening alloy used in a number of aerospace, nuclear energy and chemical processing applications.

Stainless Steel Grade 17-4PH, also known as 17-4 Precipitation Hardening, UNS S17400, or AISI 630, is a martensitic precipitation-hardening stainless steel. It has a metallic silver-grey appearance, similar to other stainless steels with a smooth surface finish which can be polished.17-4PH Stainless Steel Sheet is renowned for its remarkable blend of properties that make it an ideal choice for various applications across industries. This precipitation-hardening stainless steel combines high strength, excellent corrosion resistance, and superior mechanical properties at temperatures up to 600°F (316°C).

Shop 17 4 Stainless Steel Sheet/Plate for aerospace and thermal applications. Meets ASTM F899 and available in full size and custom cut at OnlineMetals.com. UPS Rate Increases on Long Lengths!17-4 is a precipitation-hardened chromium-nickel alloy. Excellent corrosion resistance, physical properties, and strength. Most common of the PH alloys, and considered to have the best weldabilty.17-4 PH steel (AMS 5604) is a grade of martensitic, precipitation-hardening stainless steel with the additions of chromium, nickel, and copper. 17-4 stainless steel has a valuable combination of high strength, good corrosion resistance, and toughness in both base metals and welds.Sheet. Strip. Hardness. Rockwell C28. Rockwell C30. Rockwell C35. Rockwell C40. Rockwell C42. Rockwell C45. Not Rated. Tolerance Rating. Oversized. Undersized. Standard. Tight. Yield Strength. . Also known as Project 70+, this material machines faster with less wear on cutting tools than standard 17-4 PH stainless steel. Shim Stock. Shim Stock.

17-4 stainless has high tensile strength and hardness and excellent corrosion resistance up to high temperatures. It is typically used in gate valves, chemical processing equipment, pump shafts, gears, ball bearings, bushings, and fasteners.The 17-4 stainless steel grade is an age-hardening martensitic alloy that combines high corrosion resistance and strength. Unlike conventional martensitic steels, it weldable by all standard methods, and achieves hardening with simple low-temperature treatment over a .17-4PH is a martensitic, precipitation-hardening stainless steel that provides an outstanding combination of high strength and hardness along with excellent corrosion resistance.17-4 Stainless Steel is a highly versatile and widely used precipitation-hardening alloy used in a number of aerospace, nuclear energy and chemical processing applications.

Stainless Steel Grade 17-4PH, also known as 17-4 Precipitation Hardening, UNS S17400, or AISI 630, is a martensitic precipitation-hardening stainless steel. It has a metallic silver-grey appearance, similar to other stainless steels with a smooth surface finish which can be polished.

17 4 ph stainless steel material properties

17 4 ph stainless steel data sheet

Discover how choosing the right metal sheet can transform your projects, whether it’s construction, manufacturing, or artistic endeavors. By the end, you’ll have a clear understanding of which metal sheet suits your needs best and why.

17-4ph sheet metal|17 4 ph equivalent material