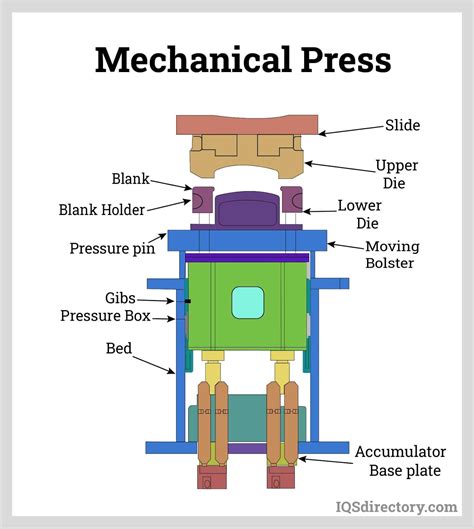

how to make a sheet metal stamping die A stamping die is a special, one-of-a-kind precision tool that cuts and forms sheet metal into a desired shape or profile as the sheet metal is pressed, or stamped, between two mating components (see Figure 1). A die . Air bending is the most common type of 3 Types Of Bending used in sheet metal shops today. In this process the workpiece comes in contact with the outside edges of the die, as well as the punch tip.

0 · stamping dies manufacturing process

1 · stamping die standards and requirements

2 · stamping die clearance

3 · sheet metal stamping at home

4 · sheet metal hole stamping tool

5 · sheet metal forming dies

6 · how transfer metal stamping tools

7 · design tooling for stamping dies

A junction box – also known as an ‘electrical box’, ‘jbox’, ‘or ‘terminal box’ – is a protective box where wires are interconnected. Junction boxes are often built into the plaster of a wall, in the ceiling, or within concrete.

Step 4: Preparing the Sheet Metal for Stamping For this particular set of dies, I needed a piece of sheet metal with a few features to ensure that it would stay in the correct position during the stamping process. Part of the Fundamental Manufacturing Processes Video Series, this program will help you better understand how stamping dies operate. You will explore sheet metal deformation and.

A stamping die is a special, one-of-a-kind precision tool that cuts and forms sheet metal into a desired shape or profile as the sheet metal is pressed, or stamped, between two mating components (see Figure 1). A die . A stamping die is a special, one-of-a-kind precision tool that cuts and forms sheet metal into a desired shape or profile. The die's cutting and forming sections typically are made from special types of hardenable steel . Want to make a high-quality stamping die? Check out these nine essential design points you need to keep in mind for optimal performance and productivity.

Metal stamping is a high-volume manufacturing process that transforms flat metal sheets into specific shapes using mechanical forces. This versatile technique is crucial in various industries, including automotive, . Part 1 of 3 - YouTube. I want to know what you think! Scroll down and leave your comments and suggestions.Homemade Hydraulic Press Stamping Sheet Metal with Homemade Die. Forming . By following these steps, a high-quality sheet metal stamping die capable of producing accurate and consistent metal stamping parts for a wide of applications, such as the production of automotive parts, household .This blog post will cover over the basics of sheet metal stamping dies and how a stamping simulation can be used to improve quality. Learn more. Get a Project Quote. . Because of the significant capital investment required to create a .

In this video, I show how I make a DIY die set for bending and forming metal with my Harbor Freight 20 Ton hydraulic press. It's very simple and works excell. Mold Maker in Taiwan - Intertech Machinery Inc.We manufacture plastic injection molds, custom molds, silicone Medical Mold, liquid silicone Medical Mold, LSR.

On this episode of Make It Kustom, we build a press form step-by-step to emboss or stamp a Chevy emblem into sheet metal without warping. Sheet metal stampin. Sheet Metal Stamping is a low-cost high-speed manufacturing process that produces a high volume of identical metal components, which has contributed importan. Die Design Part-2Sheet metal product design

Automatic Transfer Die Stamping. All the processes are completed on one machine, and the parts are transferred between the processes through the robotic arm. . This is the cost price of a set of one meter long continuous die for ordinary sheet metal parts. The same size car mold quote plus 20%, 16666 US dollars * 1.2 = 20000 US dollars. Learn the steps of the metal stamping process, from product design all the way through delivery. This 7-step process includes design, die machining, processi.

Patreon Link: https://www.patreon.com/user?u=889861Instagram Link: https://www.instagram.com/craigsmachineshop/Please direct all correspondence to:Craig's Ma. Vukota Boljanovic, Ph.D., has nearly 50 years of experience in applied engineering in the aircraft and automotive industries, as well as academia.He has performed extensive research in manufacturing engineering, including the impact of design and modification on sheet metal dies, jigs and fixtures, and process selection, aircraft assembly, and inspection tool and .Metal dies for stamping are beautiful examples of craftsmanship. They are used on many surfaces like leather, metal and wood. They are used to add depth and detail for design surfaces. Lightly heat the metal die and create a wood-burning effect or use leather tooling to emboss a .

stamping dies manufacturing process

Author’s Note: Since it’s been about 15 years since my Die Basics 101 series, I’ve been asked to write another series of articles on the fundamentals of stamping die design and construction. As experienced toolmakers and engineers retire, many companies have struggled to find and hire individuals with basic metal stamping tooling knowledge.Changdong is a professional metal stamping die maker in China,producing progressive die, transfer die and tandem die. As one of stamping die manufacturer, the company also makes metal prototyping parts for short-run production for the customers in 16 countries. . IntroductionIt is known that a crucial part of the production of a sheet metal .

metal slug game boy color box cover

Blanking tool Design in NX (Tool and Die Making)In This tutorial We'll discuss on Complete Blanking Die Designing🟢 For advance Offline & Online Corporate Tr. Editor's Note: In this series, tool-and-die expert Art Hedrick presents an overview of metal stamping. Part I focused on the various careers in the metal stamping industry. Part II discusses stamping materials and equipment; Part .

Study with Quizlet and memorize flashcards containing terms like In a sheet metal stamping operation, the scrap part cut out is referred to as a: Blank Shear-scrap Medallion Slug, If the blanking force in a sheet metal operation increases . We’ll always have an internal discussion where our design team and toolmakers review the die and components to make sure the tool will make the part as expected. Then we build die part components, punch components, .Sheet metal stamping dies are essential tools employed in the stamping process to shape and cut metal sheets into desired forms. They consist of two main parts: the punch and the die. The punch is the component that applies force to the metal sheet, while the die serves as the mold that defines the shape of the final product. I want to know what you think! Scroll down and leave your comments and suggestions.Homemade Hydraulic Press Stamping Sheet Metal with Homemade Die. Forming .

An Impression die is basically a die/metal form/mold that one presses metal into, in order to create an impression. Example/typical metals include Sterling, Fine Silver, Gold, Brass, Copper, Bronze. The idea is to use metals that are weaker than the steel used to make the die, so as not to damage the tool. There are three main components associated with sheet metal stamping. Those are the forming die, the piece of sheet metal, and the press machine. Any single component may require different steps to get it into its final form. The following guide will help outline the most common processes that occur during sheet metal stamping. FormingDiscover how sheet metal stamping can change your production line and yield. . Pressing: The press then comes down with controlled force, pressing the metal sheet between the die and punch. This action forms the metal into the desired shape, with the die acting as the mold and the punch forcing the metal into place. The sheet metal stamping process simulations are then integrated with die structural analysis in order to optimize the structural design of the die. Based on the compromise programming approach, the multi-objective topology optimization problem is solved for different loading conditions and the criteria weights are determined using the AHP method.

Want to make a high-quality stamping die? Check out these nine essential design points you need to keep in mind for optimal performance and productivity. . My extensive experience has allowed me to become an expert in the fields of sheet metal fabrication, machining, mechanical engineering, and machine tools for metals. I am constantly .Die Tooling Preventive Maintenance for the Sheet Metal Stamping Industry: A Comprehensive, Step-by-Step Guide to Control Your Sheet Metal Stamping Process Thomas J. Ulrich 4.2 out of 5 stars 5

The sheet metal stamping process is a very fast and precise manufacturing process. But what if, press tool is not working efficiently or it takes many more operations to produce stamped parts. So it is very important to design an economy friendly and time-saving press tools. Steps to design any Sheet metal stamping press tool or die.

My metalworking background is in sheet metal shaping and metal finishing though, so how the metal has to move comes more naturally I suppose. I also only used it for a few panels, such as a massive flare almost like a dimple die but odd shape and about 6” across

stamping die standards and requirements

stamping die clearance

Simply put, “metal fabrication” is defined as creating products or structures by cutting, bending, and/or assembling metal material. It’s largely considered a value-added process as it consists of putting together actual products or structures from metal raw material.

how to make a sheet metal stamping die|design tooling for stamping dies