sheet metal box making In this Instructable I'm going to walk you through how to make one of these simple sheet metal boxes! If you are just beginning to work with sheet metal I recommend also checking out my . When nailing the box, use light, careful blows rather than heavy swings of the .

0 · sheet metal box layout

1 · sheet metal box fabrication

2 · sheet metal box drawing

3 · sheet metal box design guide

4 · sheet metal box design

5 · sheet metal blueprints

6 · metal box fabrication

7 · metal box design

Now, if the junction boxes are indeed grounded (e.g. via metal conduit as discussed above), here's how you can ground receps. #1: Run a wire to a ground clip or screw (often there's a hole tapped for a #10-32 screw in the back of the steel box).

In this Instructable I'm going to walk you through how to make one of these simple sheet metal boxes! If you are just beginning to work with sheet metal I recommend also checking out my .A Riveted Metal Box With Lid: This is a practice box, so it's not very nice-looking. You can build it to get a feel for working with various sheet metal tools: metal .

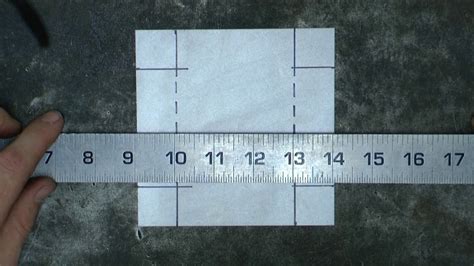

How To Make a Sheet Metal Box - Shop Class Project. This is another great beginner sheet metal project I use in my shop classes. I use it to teach print reading skills and . Creating a 22 gauge sheetmetal box from scratch. Video tutorial includes cutting the sheetmetal template and bending the pieces on my 24" Grizzly Box & Pan . Challenging but Achievable: How to Make a Sheet Metal Box. Max Maker. 111K subscribers. Subscribed. 654. 18K views 3 years ago. __________________________ My Favourite Tools (Through .How to Make a Sheet Metal Box: 1) first you want to make an expanded template for your box out of cardboard, paper, etc. ( a flat version of your box. I have a graph paper drawing in the pics below, but its not for this box) 2) trace your .

to make: 1_decide what size box you wish to make. the box pictured is 6-1/4" w x 8-1/4"d x 3-1/2"h. then make a template. draw an outline of the desired size box on the large sheet of paper (I used a roll of craft paper .

What is a Sheet Metal Box? A Sheet Metal Box is a container crafted from thin, flat pieces of metal. These boxes can vary in size, shape, and material, depending on their intended use. They are known for their durability, . here i am making a 16 ga round steel box. this is a quick way to make a round cap shape fast start to finish this was 45 minutes to build. forming a round bo.

_____My Favourite Tools (Through Amazon Influencer Shop): https://www.amazon.com/shop/depyrol_____Podcast:https://i.

How to develop and fold sheet metal in Autodesk Inventor

Fabricating a sheet metal box can seem daunting, but with the right tools and techniques, it can be a straightforward process. In this article, we’ll go over the steps to fabricate a sheet metal box, including cutting, bending, and welding. Step 1: Designing the Box. Before you start fabricating your sheet metal box, you’ll need to design it. I want to use Inventor to make a real sheet metal box. This box has a bottom, four sides, and folded over to the inside flanges along the four edges. Very standard. If I design from a flat sheet, the piece has a cross shape, with little 45 degree cuts at the corners of the cross arms so that when you fold in the edge flanges they don't interfere.

The sides are the most challenging part to make, you can make a little tool to help which is shown in the photos. It just a strip sheet metal 15mm wide with 45 degrees cut on each end. Cut a sheet 200 X 110mm to make a start. Click on the photos for directions and the drawing with all the measurements you need. #sheetmetal Sheet Metal Design Sheet Metal FabricationSheet Metal Do you want to become an expert of Modeling on SolidWorks, then this video exactly for you..

About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy & Safety How YouTube works Test new features NFL Sunday Ticket Press Copyright .sheet metal box making! sarfraz saifi moshin saifi! #moshin saifi#sheet metal brake#diy sheet metal#sheet metal#metal art ideas#how to#how to make#fabricatio.

cut away ONLY the blackened area on the drawing. this will allow you to tuck the corners making the water tight seam. Step 3: Pre-Bending. using a screwdriver or wide, blunted chisel, slightly crease the corners. the 45 degree creases will be towards the top, and from the top. the 90 degree creases that follow your marks will be towards and .Outdoor Wall Mounted Bike Rack. Type: Standard BicycleSheet Metal Tool Tray: This is the last sheet metal project I assign in my level one manufacturing class. This is the first multiple part project my students work with in class that they will have to assemble together. . AND A SIMPLE BOX. These tool trays are great to have around the house or workshop. I have several of them around my .

How steel sheet boxes are made: A skilled boy making perfect metal box without use of any electricity or welding, Making technique of a storage trunk with st.

This video is the fabrication part of how to make a tool tray as discussed in the video posted on May 17th titled "Sheet Metal is Fun #3 Part 1" were I disc. Hi, I've been modelling up a sheet metal assembly and am rather inexperienced with inventor. I have searched online but couldn't find any specific information. I want to make a lid for this sheet metal compartment which is .

i made a sheet metal box in class it is really simple mostly all you will need is a piece of metal the layout some shears,a hammer a spot welder, a sheet medal machine, and a sand blaster or sand paper.the struggles you will have mostly with this project is trying to make the folds line up to spot weld. but any ways lets get started. This week we needed a custom sheet steel box with rounded edges similar to an electrical box. These are the steps we took to make it.Get a free sticker by e.

Using sheet metal file to create a boxCUSTOM SIZED STAINLESS STEEL BOX - TCS series; Custom sized stainless steel sheet metal box with a stainless; steel sheet cover. All W, H, and D dimensions can be specified; as 60~ 400mm for W and D dimensions and 40~120mm for; H dimension in 1mm intervals. NEW PRODUCT; DETAILS Please subscribe to my channel to support me:https://youtube.com/channel/UCajOnf8bb8Zw7pKNhyKLc6wFor this project I used 1 mm metal sheet:1 Drew the bending .

About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy & Safety How YouTube works Test new features NFL Sunday Ticket Press Copyright . The choice of material for custom sheet metal boxes is a crucial decision that impacts the box’s overall performance and longevity. Stainless steel, aluminum, and copper are commonly used materials due to their excellent strength-to .If you are able to do normal four sided box folds then for the reverse flap you would have the option to make a normal box and then attach a separate plate to one side to create the riser flap. This could be attached with welding, spot welding, rivets or sheet metal screws.

This is how I made my home made box pan brake for a fraction of the cost of a shop bought version. It can bend up to 2mm cold rolled steel with ease and is w. About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy & Safety How YouTube works Test new features NFL Sunday Ticket Press Copyright .

sheet metal box layout

sheet metal box fabrication

An electrical junction box (also known as a "jbox") is an enclosure housing electrical connections. [1] Junction boxes protect the electrical connections from the weather, as well as protecting people from accidental electric shocks.

sheet metal box making|sheet metal box layout