battery bank junction box 3/8" Heavy Duty Dual Studs Battery Junction Post Terminal Kit, Ampper 2 Studs M10 Bus Bar Power and Ground Junction Block Distribution (W/Cover, Red and Black) This article covers everything you need to know about welding thin sheet metal: from tips for beginners to advanced welding techniques that experienced professionals use under difficult circumstances.

0 · physical location of battery junction

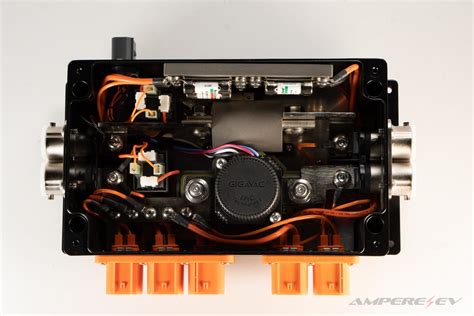

1 · junction box in electrical vehicle

2 · high voltage junction box automotive

3 · high voltage battery junction box

4 · high current battery junction box

5 · battery terminal junction block

6 · battery junction box ford f350

7 · 2022 f350 battery junction box

We offer a range of metal fabrication services to meet your needs, including welding, turret punching and metal folding. In addition to our broad range of tried and tested products, our team specialises in custom design, to suit individual client needs.

The Battery Bank Junction Box contains a 30 A dc circuit breaker and a 0.5 A dc ground-fault protection device (GFPD).The Battery Bank Junction Box contains a 30 A dc circuit breaker and a 0.5 A dc .Battery Bank Junction Box, LabVolt Series 3 © Festo Didactic General Description The Battery Bank Junction Box contains a 30 A dc circuit breaker and a 0.5 A dc ground-fault protection .3/8" Heavy Duty Dual Studs Battery Junction Post Terminal Kit, Ampper 2 Studs M10 Bus Bar Power and Ground Junction Block Distribution (W/Cover, Red and Black)

.68The battery junction box (BJB) is the controlling part of the BMS. It measures several high-voltages throughout the overal BMS, accurately and redundantly measures the system's current and measures isolation resistance between the .Figure 1 presents a typical BMS architecture containing a battery management unit (BMU), cell supervisor unit (CMU) and a battery junction box (BJB). A BMU typically has a microcontroller .

The Battery Bank Junction Box contains a 30 A dc circuit breaker and a 0.5 A dc ground-fault protection device (GFPD). Reflecting the commitment of Festo Didactic to high quality . The massive electrification efforts happening in the automotive industry are driving the need to reduce the complexity of BMS by adding electronics in the junction box while enhancing system safety. A pack monitor .

Learn how a novel electric vehicle (EV) capacitive-isolation daisy-chain data acquisition IC enables a streamlined junction box time-aligned with battery cell voltage and .

This presentation will discuss the different trends and topologies for battery-junction-box or battery-disconnect units in electric vehicles. We will describe the challenges . Exploring the new NXP solution for the high voltage battery junction box (BJB). BJB is a key function serving high voltage systems with accurate voltage, chassis isolation and .The Battery Bank Junction Box contains a 30 A dc circuit breaker and a 0.5 A dc ground-fault protection device (GFPD).

physical location of battery junction

Battery Bank Junction Box, LabVolt Series 3 © Festo Didactic General Description The Battery Bank Junction Box contains a 30 A dc circuit breaker and a 0.5 A dc ground-fault protection device (GFPD). Specifications Parameter Value Junction Box Contents One resettable battery bank circuit breaker and one ground-fault protection device (GFPD)

3/8" Heavy Duty Dual Studs Battery Junction Post Terminal Kit, Ampper 2 Studs M10 Bus Bar Power and Ground Junction Block Distribution (W/Cover, Red and Black)The battery junction box (BJB) is the controlling part of the BMS. It measures several high-voltages throughout the overal BMS, accurately and redundantly measures the system's current and measures isolation resistance between the battery and the chassis for isolation monitoring.Figure 1 presents a typical BMS architecture containing a battery management unit (BMU), cell supervisor unit (CMU) and a battery junction box (BJB). A BMU typically has a microcontroller (MCU), which manages all of the functions within the battery pack.

The Battery Bank Junction Box contains a 30 A dc circuit breaker and a 0.5 A dc ground-fault protection device (GFPD). Reflecting the commitment of Festo Didactic to high quality .

The massive electrification efforts happening in the automotive industry are driving the need to reduce the complexity of BMS by adding electronics in the junction box while enhancing system safety. A pack monitor can locally measure the voltages before and after the relays and the current through the battery pack. Learn how a novel electric vehicle (EV) capacitive-isolation daisy-chain data acquisition IC enables a streamlined junction box time-aligned with battery cell voltage and temperature measurements. This presentation will discuss the different trends and topologies for battery-junction-box or battery-disconnect units in electric vehicles. We will describe the challenges and solutions to measure different parameters such as voltage, current, temperature and insulation resistance, using integrated analog front ends. Exploring the new NXP solution for the high voltage battery junction box (BJB). BJB is a key function serving high voltage systems with accurate voltage, chassis isolation and current measurements. All ASIL compliances, performances and communication options will .

The Battery Bank Junction Box contains a 30 A dc circuit breaker and a 0.5 A dc ground-fault protection device (GFPD).Battery Bank Junction Box, LabVolt Series 3 © Festo Didactic General Description The Battery Bank Junction Box contains a 30 A dc circuit breaker and a 0.5 A dc ground-fault protection device (GFPD). Specifications Parameter Value Junction Box Contents One resettable battery bank circuit breaker and one ground-fault protection device (GFPD)

3/8" Heavy Duty Dual Studs Battery Junction Post Terminal Kit, Ampper 2 Studs M10 Bus Bar Power and Ground Junction Block Distribution (W/Cover, Red and Black)

The battery junction box (BJB) is the controlling part of the BMS. It measures several high-voltages throughout the overal BMS, accurately and redundantly measures the system's current and measures isolation resistance between the battery and the chassis for isolation monitoring.Figure 1 presents a typical BMS architecture containing a battery management unit (BMU), cell supervisor unit (CMU) and a battery junction box (BJB). A BMU typically has a microcontroller (MCU), which manages all of the functions within the battery pack.

junction box in electrical vehicle

The Battery Bank Junction Box contains a 30 A dc circuit breaker and a 0.5 A dc ground-fault protection device (GFPD). Reflecting the commitment of Festo Didactic to high quality .

The massive electrification efforts happening in the automotive industry are driving the need to reduce the complexity of BMS by adding electronics in the junction box while enhancing system safety. A pack monitor can locally measure the voltages before and after the relays and the current through the battery pack. Learn how a novel electric vehicle (EV) capacitive-isolation daisy-chain data acquisition IC enables a streamlined junction box time-aligned with battery cell voltage and temperature measurements. This presentation will discuss the different trends and topologies for battery-junction-box or battery-disconnect units in electric vehicles. We will describe the challenges and solutions to measure different parameters such as voltage, current, temperature and insulation resistance, using integrated analog front ends.

Still, it’s possible to weld thin sheet metal using the MIG (GMAW), TIG (GTAW), and stick (SMAW) processes. But MIG and TIG provide the best results. This article will teach you how to weld thin gauge metal using each arc welding process and present the common pitfalls beginners make.

battery bank junction box|2022 f350 battery junction box