burr allowance in sheet metal Today, metalformers should use standards—not rules of thumb—to establish burr-height limits on stamped parts. Two such standards: DIN 9830 (German) and NF E81-010 . For each of the following sets of numerical values, calculate the power in the interconnection and state whether the power is flowing from A to B or vice versa. a) i = 10A, v = 125V b) i = 5A, v = -240V c) i = -12A, v = 480V d) i = -25A, v = .

0 · yarn burr standards

1 · sharp edge and burr standard

2 · maximum burr allowance

3 · burr standard for sheet metal

4 · burr limit for sheet metal

5 · burr allowance chart

6 · acceptable burr height for metal

7 · acceptable burr height

PV junction box with MC4 compliant connectors. When purchasing solar modules, always have a look at the IP rating of the PV junction box. A completely water tight junction box carries IP 67. IP65 rated PV junction box. How does the PV junction box protect the solar panel? Most photovoltaic junction boxes have diodes. The function of the diodes .

The maximum acceptable burr height for a metal stamping is equal to 10 percent of sheetmetal thickness. The above statement would be true if all stampings were produced from low-carbon steel less than 0.050 in. thick, . Example: If you work in the automotive industry, the burr standard cannot be generalised between Bumper and Mounting bracket of Engine, even though both of them are .Burr allowance is generally 10% of the thickness of the sheet material. To minimize instances and severity of burrs, avoid sharp corners and complex cutouts when possible. Today, metalformers should use standards—not rules of thumb—to establish burr-height limits on stamped parts. Two such standards: DIN 9830 (German) and NF E81-010 .

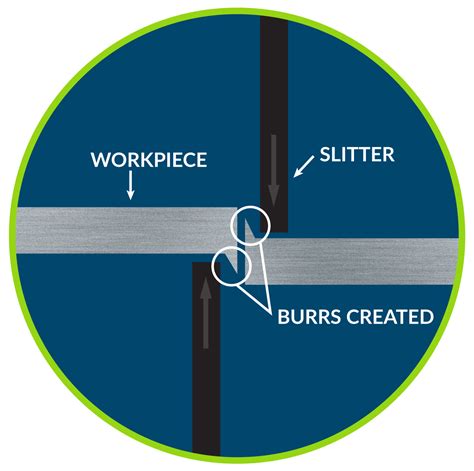

leaves an unavoidable “feather edge” burr along the outside material edge. Piercing: Holes-Minimum diameter of holes should be equal or greater than 1.2 X material thickness, and 2X . Five standard burr classes have been developed that help specify burr size, how they were formed and difficulty of removal. Brushing is a common deburring solution, and newer technology is contributing to longer overall .

Typically, the proper punch-to-die clearance in the punching station is the largest clearance that produces a high-quality shear band and a clean break edge without producing a burr.

Each shop seems to have a slightly different way of looking for burrs, as well as differing expectations of what burrs are and degrees of acceptability. Each inspection technique yields .The clearances range from about 6% of the sheet material thickness for mild steel up to 16% or even higher as the sheet metal tensile strength exceeds 1400 MPa. A study C-2 compared the tool wear and burr height formation associated with . The maximum acceptable burr height for a metal stamping is equal to 10 percent of sheetmetal thickness. The above statement would be true if all stampings were produced from low-carbon steel less than 0.050 in. thick, using typical punch-to-die cutting clearances. Example: If you work in the automotive industry, the burr standard cannot be generalised between Bumper and Mounting bracket of Engine, even though both of them are sheet metal parts.

Burr allowance is generally 10% of the thickness of the sheet material. To minimize instances and severity of burrs, avoid sharp corners and complex cutouts when possible.III) When the drawing does not specify burr size or safe handling requirements, product may be supplied with a maximum burr of up to 5% of the material thickness. Today, metalformers should use standards—not rules of thumb—to establish burr-height limits on stamped parts. Two such standards: DIN 9830 (German) and NF E81-010 (French). Both classify acceptable burr heights relative to the workpiece-material thickness and its tensile strength.leaves an unavoidable “feather edge” burr along the outside material edge. Piercing: Holes-Minimum diameter of holes should be equal or greater than 1.2 X material thickness, and 2X material thickness for stainless steel or high tensile materials. Edge-to-hole - Allow 2x material thickness (“web”) to prevent bulging of material Forming:

Five standard burr classes have been developed that help specify burr size, how they were formed and difficulty of removal. Brushing is a common deburring solution, and newer technology is contributing to longer overall brush life.

Typically, the proper punch-to-die clearance in the punching station is the largest clearance that produces a high-quality shear band and a clean break edge without producing a burr.Each shop seems to have a slightly different way of looking for burrs, as well as differing expectations of what burrs are and degrees of acceptability. Each inspection technique yields different results.The clearances range from about 6% of the sheet material thickness for mild steel up to 16% or even higher as the sheet metal tensile strength exceeds 1400 MPa. A study C-2 compared the tool wear and burr height formation associated with . The maximum acceptable burr height for a metal stamping is equal to 10 percent of sheetmetal thickness. The above statement would be true if all stampings were produced from low-carbon steel less than 0.050 in. thick, using typical punch-to-die cutting clearances.

Example: If you work in the automotive industry, the burr standard cannot be generalised between Bumper and Mounting bracket of Engine, even though both of them are sheet metal parts.Burr allowance is generally 10% of the thickness of the sheet material. To minimize instances and severity of burrs, avoid sharp corners and complex cutouts when possible.III) When the drawing does not specify burr size or safe handling requirements, product may be supplied with a maximum burr of up to 5% of the material thickness. Today, metalformers should use standards—not rules of thumb—to establish burr-height limits on stamped parts. Two such standards: DIN 9830 (German) and NF E81-010 (French). Both classify acceptable burr heights relative to the workpiece-material thickness and its tensile strength.

leaves an unavoidable “feather edge” burr along the outside material edge. Piercing: Holes-Minimum diameter of holes should be equal or greater than 1.2 X material thickness, and 2X material thickness for stainless steel or high tensile materials. Edge-to-hole - Allow 2x material thickness (“web”) to prevent bulging of material Forming: Five standard burr classes have been developed that help specify burr size, how they were formed and difficulty of removal. Brushing is a common deburring solution, and newer technology is contributing to longer overall brush life.

Typically, the proper punch-to-die clearance in the punching station is the largest clearance that produces a high-quality shear band and a clean break edge without producing a burr.

Each shop seems to have a slightly different way of looking for burrs, as well as differing expectations of what burrs are and degrees of acceptability. Each inspection technique yields different results.

sheet metal fabrication for electronics manufacturing industry

yarn burr standards

sharp edge and burr standard

There is more than one common type of CNC machine due to the many different CNC machine processes, such as milling, drilling, laser cutting, EDM cutting, lathe work, and more. Every type of process has numerous options for axes and positioning systems, leading to a wide range of classifications.

burr allowance in sheet metal|yarn burr standards