electric motor enclosure definitions The more common of these enclosure types are Open machines: Drip-Proof (ODP), and Weather Protected (WPI/WPII); Totally Enclosed machines: Fan Cooled (TEFC), Pipe-Ventilated . Welcome to UMF Medical's Product Categories. We offer a wide range of high-quality, durable products for healthcare settings, including Power Exam Tables, Power Procedure Chairs, and Pediatric Tables—all designed for patient safety and comfort.

0 · types of electric motor enclosures

1 · totally enclosed motor

2 · totally enclosed fan cooled motor

3 · totally enclosed air over motor

4 · open drip proof motors

5 · odp enclosure vs tefc

6 · motor enclosure opsb meaning

7 · motor enclosure odp vs tefc

$16.49

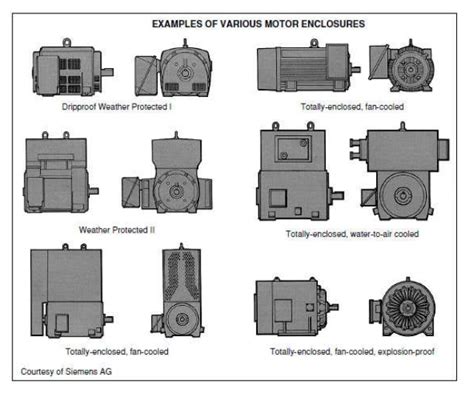

Type 7 and 10 enclosures are designed to contain an internal explosion without causing an external hazard. Type 8 enclosures are designed to prevent combustion through the use of oil . Have you ever noticed the different types of enclosures that surround electric motors? The National Electrical Manufacturers Association (NEMA) has established over 20 different enclosure types under their MG1 .The article discusses motor enclosure types as outlined by the NEMA standards, focusing on open and totally enclosed motors. Open motors feature ventilating openings for cooling, while totally enclosed motors restrict air exchange. NEMA Motor Enclosures. According To EEP (Electrical Engineering Portal); NEMA standards MG1-1.25 through 1.27 defines more than twenty different enclosures types under the categories of open machines, .

The more common of these enclosure types are Open machines: Drip-Proof (ODP), and Weather Protected (WPI/WPII); Totally Enclosed machines: Fan Cooled (TEFC), Pipe-Ventilated .

NEMA (National Electrical Manufacturers Association) developed a set of standards relating to electric motors that include design classes, frame sizes, enclosures, and configurations. A . Nov 4, 2012

Type 9 Enclosures are for use in indoor locations classified as Class II, Groups E, F, Or G, as defined in the National Electrical Code. Type 10 Enclosures are constructed to meet the . NEMA standards MG1-1.25 through 1.27 define more than 20 types of enclosures under the categories of open machines, totally enclosed machines, and machines with encapsulated or sealed windings. The 7 most common types of .Type 7 and 10 enclosures are designed to contain an internal explosion without causing an external hazard. Type 8 enclosures are designed to prevent combustion through the use of oil-immersed equipment. Type 9 enclosures are designed to prevent the ignition of combustible dust. NEMA enclosure standard for electrical motors. The enclosures of electrical motors are standardized by NEMA (National Electrical Manufacturers Association) as: Ventilation openings in shield and/or frame prevents drops of liquid from falling into motor within up to 15 degree angle from vertical.

types of electric motor enclosures

Have you ever noticed the different types of enclosures that surround electric motors? The National Electrical Manufacturers Association (NEMA) has established over 20 different enclosure types under their MG1 standards, which categorize motors as open, totally enclosed, or sealed windings designs.The article discusses motor enclosure types as outlined by the NEMA standards, focusing on open and totally enclosed motors. Open motors feature ventilating openings for cooling, while totally enclosed motors restrict air exchange. NEMA Motor Enclosures. According To EEP (Electrical Engineering Portal); NEMA standards MG1-1.25 through 1.27 defines more than twenty different enclosures types under the categories of open machines, totally enclosed machines, and machines with encapsulated or sealed windings.

The more common of these enclosure types are Open machines: Drip-Proof (ODP), and Weather Protected (WPI/WPII); Totally Enclosed machines: Fan Cooled (TEFC), Pipe-Ventilated (TEPV), Air Over (TEAO), Non-Ventilated (TENV), Air to Air (TEAAC), Water to Air (TEWAC), and Explosion-proof (XP); and those with encapsulated or sealed windings.NEMA (National Electrical Manufacturers Association) developed a set of standards relating to electric motors that include design classes, frame sizes, enclosures, and configurations. A basic knowledge of NEMA standards can prove invaluable when looking for a . NEMA enclosure classifications are developed by NEMA and used in the U.S./American market. Ingress Protection - IP - ratings are developed by the European Committee for Electro Technical Standardization (CENELEC) (described IEC/EN 60529), and specifies the environmental protection and enclosure provided.Type 9 Enclosures are for use in indoor locations classified as Class II, Groups E, F, Or G, as defined in the National Electrical Code. Type 10 Enclosures are constructed to meet the applicable requirements of the Mine Safety and Health Administration.

NEMA standards MG1-1.25 through 1.27 define more than 20 types of enclosures under the categories of open machines, totally enclosed machines, and machines with encapsulated or sealed windings. The 7 most common types of .

Type 7 and 10 enclosures are designed to contain an internal explosion without causing an external hazard. Type 8 enclosures are designed to prevent combustion through the use of oil-immersed equipment. Type 9 enclosures are designed to prevent the ignition of combustible dust.

NEMA enclosure standard for electrical motors. The enclosures of electrical motors are standardized by NEMA (National Electrical Manufacturers Association) as: Ventilation openings in shield and/or frame prevents drops of liquid from falling into motor within up to 15 degree angle from vertical. Have you ever noticed the different types of enclosures that surround electric motors? The National Electrical Manufacturers Association (NEMA) has established over 20 different enclosure types under their MG1 standards, which categorize motors as open, totally enclosed, or sealed windings designs.

cardboards electric box

The article discusses motor enclosure types as outlined by the NEMA standards, focusing on open and totally enclosed motors. Open motors feature ventilating openings for cooling, while totally enclosed motors restrict air exchange. NEMA Motor Enclosures. According To EEP (Electrical Engineering Portal); NEMA standards MG1-1.25 through 1.27 defines more than twenty different enclosures types under the categories of open machines, totally enclosed machines, and machines with encapsulated or sealed windings.The more common of these enclosure types are Open machines: Drip-Proof (ODP), and Weather Protected (WPI/WPII); Totally Enclosed machines: Fan Cooled (TEFC), Pipe-Ventilated (TEPV), Air Over (TEAO), Non-Ventilated (TENV), Air to Air (TEAAC), Water to Air (TEWAC), and Explosion-proof (XP); and those with encapsulated or sealed windings.

car rim cnc machine

NEMA (National Electrical Manufacturers Association) developed a set of standards relating to electric motors that include design classes, frame sizes, enclosures, and configurations. A basic knowledge of NEMA standards can prove invaluable when looking for a . NEMA enclosure classifications are developed by NEMA and used in the U.S./American market. Ingress Protection - IP - ratings are developed by the European Committee for Electro Technical Standardization (CENELEC) (described IEC/EN 60529), and specifies the environmental protection and enclosure provided.

totally enclosed motor

totally enclosed fan cooled motor

UMF Medical is a family-owned company that produces innovative exam tables and procedure chairs with patented features for infection control and efficiency. Founded in 1955 in Johnstown, Pennsylvania, UMF Medical has a history of .

electric motor enclosure definitions|totally enclosed fan cooled motor