cnc cutting machine coolant Most machine manufacturers provide explicit instructions on the type of coolant their machine requires. For instance, manufacturers of . See more Transfer TV and Virgin Media box capability to another room/house. Hi, I have a Brown Virgin Media box attached to the external wall off our house and this box is broken and no longer holds the wires and two way.

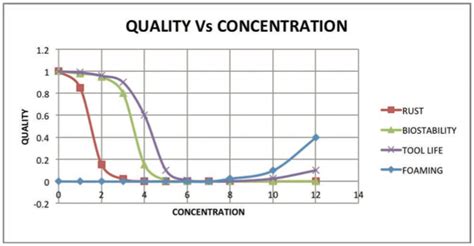

0 · machine coolant concentration chart

1 · coolant tank for cnc machine

2 · coolant system for milling machine

3 · coolant mixers for cnc equipment

4 · coolant concentration for cnc machines

5 · cnc machine coolant suppliers

6 · best semi synthetic machine coolant

7 · best coolant for cnc machine

Address: 310 Founders Ln, Suite A, Appomattox, VA 24522 .

The terms “coolant” and “lubricant” are often used interchangeably, but not all coolants are lubricants. For example, compressed air works as a coolant but has no use as a lubricant. No matter what type of CNC machining you do, CNC coolants play a Critical Role They help increase tool life and offer a better . See more

Using water alone as a coolant is never a good idea since it’s the additives in the fluid that prevent damaging rust and corrosion. Typically, most CNC machine tools use one of the following types of coolant classified as follows: See moreUsing the correct coolant for the material and type of machining results in higher production efficiency and sustained high-quality products. Recommendations vary according to the manufacturer, but for a general idea of different coolants used for other materials and . See more

Most machine manufacturers provide explicit instructions on the type of coolant their machine requires. For instance, manufacturers of . See more

Applying a water-soluble cutting fluid is as vital as the type you use. Most CNC lathes and machining centers come with through-the-tool coolant capability, and it makes sense to use it, even if you must buy new tool holders. If your machine tool can use high-pressure . See more CNC coolant improves the machining capabilities of CNC machines by reducing high-temperature build-up and facilitating chip removal. It plays a crucial role in cooling the workpiece at high speeds and lubricating the . Coolants for CNC machines help achieve optimal efficiency in a CNC shop. These coolants help reduce heat build-up, lubricate the cutting tool, and prevent discoloration and failure in machining processes such as CNC .

CNC machining coolants are often referred to as cutting fluids that serve as both coolants and lubricants during the machining process. There are two types of cutting fluids: water-based (aka water-dilutable) and non-water . Temperature Control: CNC machining produces significant heat, which can distort the workpiece and dull the tool quickly. Coolant helps dissipate this heat, ensuring consistent machining results. Lubrication: Reducing friction . Versakut 7227 is a multi-purposeful synthetic coolant for grinding, machining, milling, and other CNC applications. Made with a biostatic lube package that will not break down or be subject to selective depletion, Versakut .

CNC machining coolants are often referred to as cutting fluids that serve as both coolants and lubricants during the machining process. There are two types of cutting fluids: water-based (aka water-dilutable) and non-water-based (aka . Keeping the proper coolant concentrations helps your coolant, cutting tools, and CNC machine last longer. Why using cutting fluids will improve your machining operations? Because high temperatures can cause warping, . Chip removal: Coolants help flush away chips, preventing chip buildup and ensuring smooth machining. Lubrication: Coolants reduce friction between the cutting tool and workpiece, minimizing wear and improving .To help you determine the correct coolant concentration for your CNC machine, we have compiled a coolant concentration chart based on industry recommendations and best .

Typically, most CNC machine tools use one of the following types of coolant classified as follows: Soluble oils are the least expensive cutting fluids and the most common in machining operations. These so-called emulsions have excellent cooling and . CNC coolant improves the machining capabilities of CNC machines by reducing high-temperature build-up and facilitating chip removal. It plays a crucial role in cooling the workpiece at high speeds and lubricating the cutting tool at low speeds.

machine coolant concentration chart

Coolants for CNC machines help achieve optimal efficiency in a CNC shop. These coolants help reduce heat build-up, lubricate the cutting tool, and prevent discoloration and failure in machining processes such as CNC milling, turning, or drilling. CNC machining coolants are often referred to as cutting fluids that serve as both coolants and lubricants during the machining process. There are two types of cutting fluids: water-based (aka water-dilutable) and non-water-based (aka neat) coolants. Temperature Control: CNC machining produces significant heat, which can distort the workpiece and dull the tool quickly. Coolant helps dissipate this heat, ensuring consistent machining results. Lubrication: Reducing friction between the tool and the workpiece is crucial. Versakut 7227 is a multi-purposeful synthetic coolant for grinding, machining, milling, and other CNC applications. Made with a biostatic lube package that will not break down or be subject to selective depletion, Versakut 7227 .

12 x 24 sheet metal shed plans

CNC machining coolants are often referred to as cutting fluids that serve as both coolants and lubricants during the machining process. There are two types of cutting fluids: water-based (aka water-dilutable) and non-water-based (aka neat) coolants. Keeping the proper coolant concentrations helps your coolant, cutting tools, and CNC machine last longer. Why using cutting fluids will improve your machining operations? Because high temperatures can cause warping, melting, discoloration, or early tool failure, reduce or eliminate the heat buildup between the cutting tool and the workpiece.

Chip removal: Coolants help flush away chips, preventing chip buildup and ensuring smooth machining. Lubrication: Coolants reduce friction between the cutting tool and workpiece, minimizing wear and improving overall machining efficiency.

1250 magnetic sheet metal brake

coolant tank for cnc machine

To help you determine the correct coolant concentration for your CNC machine, we have compiled a coolant concentration chart based on industry recommendations and best practices. This chart provides a guideline for coolant concentration levels based on the type of material being machined and the cutting parameters involved. Typically, most CNC machine tools use one of the following types of coolant classified as follows: Soluble oils are the least expensive cutting fluids and the most common in machining operations. These so-called emulsions have excellent cooling and . CNC coolant improves the machining capabilities of CNC machines by reducing high-temperature build-up and facilitating chip removal. It plays a crucial role in cooling the workpiece at high speeds and lubricating the cutting tool at low speeds.

Coolants for CNC machines help achieve optimal efficiency in a CNC shop. These coolants help reduce heat build-up, lubricate the cutting tool, and prevent discoloration and failure in machining processes such as CNC milling, turning, or drilling.

CNC machining coolants are often referred to as cutting fluids that serve as both coolants and lubricants during the machining process. There are two types of cutting fluids: water-based (aka water-dilutable) and non-water-based (aka neat) coolants. Temperature Control: CNC machining produces significant heat, which can distort the workpiece and dull the tool quickly. Coolant helps dissipate this heat, ensuring consistent machining results. Lubrication: Reducing friction between the tool and the workpiece is crucial. Versakut 7227 is a multi-purposeful synthetic coolant for grinding, machining, milling, and other CNC applications. Made with a biostatic lube package that will not break down or be subject to selective depletion, Versakut 7227 .

CNC machining coolants are often referred to as cutting fluids that serve as both coolants and lubricants during the machining process. There are two types of cutting fluids: water-based (aka water-dilutable) and non-water-based (aka neat) coolants.

Keeping the proper coolant concentrations helps your coolant, cutting tools, and CNC machine last longer. Why using cutting fluids will improve your machining operations? Because high temperatures can cause warping, melting, discoloration, or early tool failure, reduce or eliminate the heat buildup between the cutting tool and the workpiece. Chip removal: Coolants help flush away chips, preventing chip buildup and ensuring smooth machining. Lubrication: Coolants reduce friction between the cutting tool and workpiece, minimizing wear and improving overall machining efficiency.

coolant system for milling machine

The IRWIN® VISE-GRIP® THE ORIGINAL 8-Inch Locking Sheet Metal Tool features oversized flat jaws specially designed to shape or crimp metal parts. It's an ideal tool for building ductwork or custom metal roofing components.

cnc cutting machine coolant|coolant tank for cnc machine