weld sheet metal with flux core Flux core welding (FCAW) is much easier to learn and master than stick (SMAW) or TIG welding (GTAW), but it can present many challenges for beginner welders.

$22.00

0 · mig flux core welding basics

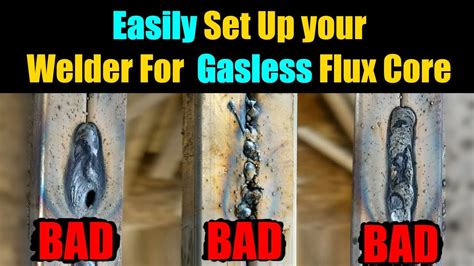

1 · flux core welding troubleshooting

2 · flux core welding techniques

3 · flux core welding setup

4 · flux core welding instructions

5 · flux core welding for dummies

6 · flux core welding for beginners

7 · flux core welding basics

Switch junction boxes do not need to be attached to wall studs and can be affixed directly to drywall or plastic. Hang each fan’s brace bar, fastening it to the ceiling joists. Attach a junction box to the bar. Run the electrical cable from the service panel to the switch box. Connect the black (hot) wire to one of the brass screws on the switch.

Welding body panels using flux-cored welding is possible, but not recommended. With FCAW the body panel will be more prone to burn through and warping due to the excessive, localized heat. There are some ways to increase your .

Today we will be going over some tricks to weld thin gauge sheet metal like body panels while avoiding wrapage. I go over 2 different techniques and several . We dive into all the details on what you need to flux core weld and how you can repair your project car rust with sheet metal and welding. How to weld sheet metal with flux core. Prepare your workpiece. Set up the metal. Adjust the welder to the proper settings. Weld the sheet metals. Remove spatter and slag. To sum up everything. Choosing the appropriate . For general purpose mild steel welding applications, a flux-cored wire with the designation E71T-11 can be used in any position, is available in a wide range of sizes and provides excellent welding characteristics for both thin .

Flux core welding (FCAW) is much easier to learn and master than stick (SMAW) or TIG welding (GTAW), but it can present many challenges for beginner welders. In this guide, we're diving deep into the art of flux core welding, breaking down the process step by step. Whether you're a greenhorn or a seasoned welder, this guide is your ticket to unlocking the secrets of .

mig flux core welding basics

Flux core welding, also known as flux-cored arc welding (FCAW), is a welding method that utilizes a continuously fed electrode with a flux core. The flux core acts as a shielding agent, protecting the weld pool from contaminants . Flux core welding, also known as flux cored arc welding (FCAW) or flux cored welding (FCW), is an arc welding method that uses a metal electrode that is shielded by a flux core. This process works by creating an arc between .Lastly, do not try to use flux cored wires for thin metal sheets as they pass more heat to the base metal. Flux-cored arc welding (FCAW) This is another option for welding a 20-gauge metal sheet but does not work as well as the MIG. .

Today we are going through some more gasless welding tips and tricks using flux core wire and looking at 4 ways you can spot weld thin sheet metal. Each one . Flux Core Welding Sheet Metal uses gas-less flux core wire which means you don’t need gas. The wire contains “Flux” which will burn while you weld. The flux acts as a protective gas that stops the weld from becoming . If you're wondering if you can use a flux core, gasless MIG welder for auto body work, this video will answer that question so that you can make an informed . Wondering if it's possible to butt weld automotive sheet metal with a flux core welder? This video can help answer that question by using a Harbor Freig.

When welding thin sheet metal with flux core, using the right techniques is crucial for achieving clean and strong welds. Here are some techniques to consider: Controlled heat input. Thin sheet metal is sensitive to excessive heat, which can cause distortion and warping. Use lower heat settings on your welding machine and maintain a steady .

Flux core welding (FCAW) is much easier to learn and master than stick (SMAW) or TIG welding (GTAW), but it can present many challenges for beginner welders. . 0.030” wire will weld 20 gauge to 14 gauge sheet metal, and 0.035” wire will weld 18 gauge to 3/16” thick steel. The thickness of the metal is important, but 0.030” and 0.035 . You should generally aim for a flux core wire of at least 18 gauge. This will allow you to weld larger body parts without worrying about the wire pulling the part away from the car. You’ll also need to make sure that your torch is clean and properly functioning. . MIG Welders are also ideal for welding sheets of metal. Gas-Cored Welder .Hello I plan to tack weld some sheet metal with 0.030" flux core wire and I'm wondering to prevent burning through, what sort of backing should I. This video was a tough one. I tried to find the easiest way to weld thin sheet metal with flux core. Flux core is usually used for heavier metals and is not .

Learn about flux-core welding, including how to weld with a flux-core welder, common problems when welding with flux-core wire and tips on safety. . the connected work piece to another piece of metal. Many metal inert gas (MIG) welding machines are capable of flux-core welding, but unlike the MIG or gas metal arc welding (GMAW) process, an .Yes, flux core welding can be used to weld car sheet metal. It is a wire welding process that uses a consumable electrode wire and a self-shielding flux to provide greater control over heat and penetration.

To weld sheet metal with flux core wire, you will need a welding machine that is capable of running flux core wire. You will also need a welding gun, a ground clamp, and a spool of flux core wire. In addition to these basic equipment, you may also need a welding helmet, welding gloves, and a welding jacket to protect yourself from the heat and .To weld sheet metal with flux-cored wire, you will need a suitable flux-cored wire, such as Select 700 GS. Set your machine to 15 V with a wire speed of 150 inches per minute. Use a DCEN polarity. The stickout should be around 3/4 “. Weld quickly, dragging at 10°. Allow the weld to cool before clearing the slag. Im installing floor pans in my 86 cutlass and I have to add some metal to the pan. so while I was at it I thought I show you some ways of spot welding and bu. I have used gasless flux core to do 20 gauge floors up to 24 gauge quarter panels. All butt joints no lap. Single spot weld, move etc. till panel welded in. I have the the .024 wire and c25 also, it is higher quality, but when just doing spots the flux core was acceptable if set up properly. I did fight pin holes more with the flux core.

Flux core's wire is usually bigger than mig wire and it has a higher melting point so you need more amps and voltage in order to do a decent minimum weld. So the minimum parameters needed to do a decent weld are usually too hot for .

To weld sheet metal you need a tig or mig with the gas bottle. These to welder you can weld at lower temps. Now you can go to power block tv and look at welding body panels. Which is the stitch or tack method. . But where it when wrong is you can weld flux core on a mig welder. So its miss used as to what one is really doing. Should not the . A Chicago Electric Flux Core 125 Welder from Harbor Freight is used to weld an automotive patch panel into place fixing a lower fender rust hole. Special th.

I try multiple different methods of wire feed welding to try and make it work, watch the video to see the results. Just a few useful things I have learned as a newbie welder butt welding sheet metal on a car. I hope this video helps out other noobs coming across these sam.

Our 7 Tips & Tricks for Beginner Flux Core Welding 1. Make Sure Your Polarity Is Correct. When welding dual shield flux core (flux-cored wire with shielding gas), most wires are DC+, which is direct current electrode positive. This means that 2/3 of the heat in the arc will be directed toward the wire.

FCAW Welding of Thin Sheet metal Welding. Flux-cored arc welding is not much popular for sheet metal welding as it will give high heat input and result in more distortion. If still FCAW is used for thin sheet welding, use a smaller diameter wire with a low welding current. Use argon + Co2 gas mixture for gas shielding or use self-shielded cored .

Flux core welding machines open up a whole world of welding to beginners, amateurs and professionals alike. . If you’re mostly going to be welding sheet metal or thin plate-like gate hinges, a 120-volt machine will serve you well. If you will need to weld thick metal for trailer frames, pipe fencing or equipment repairs, you’ll need a lot .What are the long-term prospects for flux core welding? Flux core welding has a bright future, particularly in construction and fabrication. The technology continues to advance, improving its efficiency and applications. More Resources: Flux Core vs. MIG Welding – Source: Welding Forless. Preventing Porosity in Welding – Source: Aquasol#welddotcomLets weld some thin material with flux core!Join Weld.com today, get member’s perks and support the community! https://www.youtube.com/channel/UCM. Each of the wires offers its own set of benefits and also possesses unique drawbacks. For sheet metal welding, welders will typically support flux-cored wires or solid wires as these give you the most control and versatility. The Reboot MIG welder supports both flux-cored and solid wires. Duty Cycle

flux core welding troubleshooting

A wood chip smoker box is fast, it's easy, and it's downright convenient — a simple and effective design, built to plunge every wisp of those authentic, wood-fired vapors straight into your next low-and-slow roast.

weld sheet metal with flux core|flux core welding setup