welding sheet metal arc welder Now that we’ve covered the essential considerations for different arc welding processes, let’s discuss how to prevent and fix common . See more CNC machines function using either stepper or servo motors, each possessing its own advantages and disadvantages. The name "stepper" comes from the steps made by the motor with every signal pulse. It is simple to operate, inexpensive .

0 · welding sheet metal

1 · welding aluminum sheet metal

2 · sheet metal welding process

3 · sheet metal welding machine

4 · gas arc welding sheet metal

5 · can you arc weld sheet metal

6 · arc welding thin sheet metal

7 · arc welding sheet metal

An old work electrical box is installed in a closed wall. Sometimes called a retrofit box, this type of electrical box attaches to the drywall with wings or ears that clamp the box to the drywall.

Each welding process requires specific precautions and equipment setup for a successful sheet metal weld. So, let’s discuss the preparation needed for each arc welding process before proceeding to the common problems with thin gauge welds. See more

amd sheet metal mopar

Now that we’ve covered the essential considerations for different arc welding processes, let’s discuss how to prevent and fix common . See moreWelding thin metal is challenging. There is no denying that. But, if you practice and use the tips we shared in this article, you’ll get the best chance for success. After you inevitably burn through some scrap sheets of metal and warp others, you’ll gain more experience and learn . See more Stick welding sheet metal can be done by welding DC electrode negative with 20-40A which is about the the lowest amperage settings that still allows to strike an arc. Suitable electrodes are E6011 for rusty or painted .

welding sheet metal

Arc Welding. Minimizing burn-through and distortion is essential to obtaining a good weld when gas metal arc welding thin-gauge materials. Gas metal arc welding (GMAW) is an effective method for joining light-gauge . Can a stick welder weld thin sheet metal? Find out the limitations and the minimum thickness you can arc weld and the best methods of welding sheet metals.

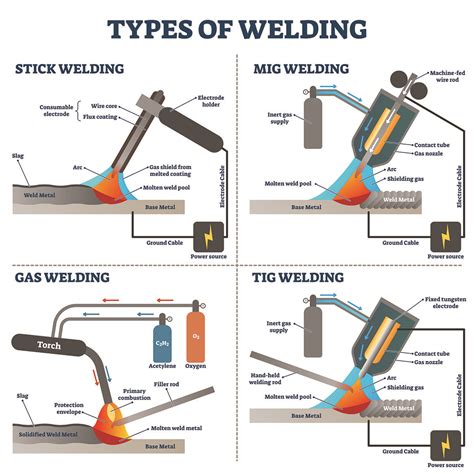

Most expert welders suggest the arc welding method when it comes to connecting slim-gauge metals. Nonetheless, you can overcome the challenges of connecting thin materials using a couple of welding procedures. The following are the main welding processes used for Sheet Metal welding: Stick Welding or SMAW. Gas Tungsten Arc Welding (GTAW or TIG) GMAW (MIG-MAG Welding) FCAW. Spot Welding. Seam welding. . Table of Contents. Why is it hard to stick weld thin metal? What are the problems when welding thin metal? What is the thinnest metal you can stick weld? What kind of power supply do you need? Which polarity is the best for . Your mig welder should have a minimum of a 4-6 amp setting, with a range of 10-30 amps recommended for weld thin sheet metal. Start with a lower-amperage setting, and practice welding with a smaller wire feed until .

welding aluminum sheet metal

sheet metal welding process

6 Methods of Sheet Metal Welding. Now, let’s take a comprehensive look at some methods for melding metal sheets. 1. MIG Welding. Metal Inert Gas welding (MIG), also known as Gas Metal Arc Welding. It .

Like other welding methods, you won't need the most powerful Stick welder to weld thin sheet metal. Instead, you can do it with a YesWelder ARC-125DS DC Stick welder, rated at 20-125 amps with an easy arc start technology.

3. Adjust Your Torch Angle. Changing the torch angle when MIG welding goes a long way to preventing burn-throughs. Make sure you adjust the angle to shorten the distance between the tip and the metal, no matter the .

Most expert welders suggest the arc welding method when it comes to connecting slim-gauge metals. . that are slimmer as compared to reedy sheet metal. Numerous welders utilize 0.023-inch diameter wires and 0.024 inches . How to Weld Auto Body Sheet Metal With a TIG Welder. The best two electrodes for welding auto body sheet metal are either ceriated tungsten or thoriated tungsten. Ditch a 1/8-inch tungsten electrode for something much . Metal inert gas (MIG) welding is an arc welding method typically used on large parts m a d e of thick material, such as structural steel parts. With this method, we feed a continuous solid wire electrode through a we lding gun into a weld pool to join two pieces together.. Considerations for MIG welding Find below the MIG Welding Sheet Metal Settings Chart which displays the recommended settings for welding different gauge thicknesses of sheet metal. To ensure optimal results, select the appropriate gauge thickness and refer to the corresponding joint gap, wire diameter, amperage, and voltage setting for your weld.

Stick welding, also known as Shielded Metal Arc Welding (SMAW), is a basic welding method where you use a flux-coated electrode and an electric current to produce the weld. It is suitable for thicker sheet metal made of steel or stainless steel but less for thin sheets due to higher heat input and less control over penetration.MIG is one of the best ways to weld 20-gauge sheet metal. MIG welding is one of the simplest to use for welding. It is an arc welding process that where you feed a solid wire electrode through a welding gun. Metal inert gas is then used to protect the weld from contaminants.

Enter the world of Flux Core Welding (FCW), a versatile technique with a unique approach to fusing materials.This method revolutionizes how welders approach sheet metal, from automotive repairs to constructing metal artworks.Grasping the principles of Flux Core Welding is essential for anyone interested in mastering this skill to achieve strong, durable, and reliable . Fun and games welding sheet metal with an arc welder - learning to weld. G'day Folks, I thought I'd start a thread here before I go and embarrass myself at weldingweb. I mean why embarrass yourself there when you can do it here? I'm in the middle of getting better at welding with my arc welder. I've reached the "I can make it stick mate" stage .

How to weld thin gauge steel similar to car body panel, down to .8mm or 1/32 of an inch thick with arc or stick welder.DisclaimerDue to factors beyond the c. The thicker the metal sheet, the higher the amperage you will need. Generally, 70 amps are ideal for welding mild or stainless steel sheets that are 1/8 inches thick. For thicker sheets, a MIG welder might work better. What Can It Weld? A 70 amp arc welder can weld stainless steel that’s 1/8-inch thick or 18-gauge. It is perfect for welding Weld metal that is less than 6mm will have a tendency to buckle and sag over time, and it can be extremely difficult to get a good bead on the metal. Weld metal that is too thick will cause you issues as well. To avoid these issues, you will want to weld thin sheet metal with flux core. Welding thin sheet metal with flux core is a great way to .

Welding Process. You will need to choose a welding process that allows you to control the heat. The best processes for this are MIG and TIG. It is possible to stick weld on thin sheet metal, but it’s harder to control the heat, it’s messy and it’s hard to master.

sheet metal welding machine

6 Methods of Sheet Metal Welding. Now, let’s take a comprehensive look at some methods for melding metal sheets. 1. MIG Welding. Metal Inert Gas welding (MIG), also known as Gas Metal Arc Welding. It involves feeding a continuous solid wire electrode into the weld puddle with a welding gun.However, some practical advice might help you with higher gauge sheet metal. Stick Welding Equipment To Weld Thin Metal Like other welding methods, you won't need the most powerful Stick welder to weld thin sheet metal. Instead, . Dive into the world of flux core welding with the Arccaptain MIG200! Our comprehensive guide unveils the secrets, techniques for mastering this challenging yet rewarding skill. From adjusting machine settings to addressing . Mig Welding Thin Sheet Metal. Mig welding is a popular and straightforward method of welding thin sheet metal. For mig welding, you don’t need much in the way of equipment. You will only need a mig welder and a .

There are some excellent sheet metal welders available, and our five reviews are based on the best welding machines for your money available online. The best TIG machine for sheet metal welding is the PRIMEWELD TIG225X 225 Amp IGBT AC/DC TIG Welder. It’s capable of welding at very low amps for fine welding and has a broad range of settings .

Stick welding, also known as shielded metal arc welding (SMAW), is a versatile and widely used welding process that involves the use of an electrode coated in flux to join metals. When it comes to sheet metal, the precise control and flexibility offered by stick welding make it an ideal choice for a range of applications. thin sheet metal arc welding, thin plate welding with two different electrode sizeshow to weld thin metal correct??? this is the technique of welding thin m. MORE: For those who like the things which YouTube doesnt, join us on a free mobile app called Telegram, under "Tractor Hoarders Group Chat", in case we get c.

Sheet metal welding is a process where the welder uses an electric arc to join two pieces of metal together. Welders usually wear protective equipment, including glasses and masks that protect them from sparks or hot particles flying out during operation. It’s also called Gas Metal Arc Welding because it uses gas and an electric arc to weld the filler metal. The welder feeds the wire electrode into the weld pool using a welding gun at high temperatures during this welding method. As the wire melts in the puddle, it stimulates the joining of the metal pieces together, firming a bead-like seam . 8. Common Welding ProcessesCommon Welding Processes • GMAW- Gas Metal Arc Welding, sometimes call Mig uses the heat of an electric arc between a continuous bare wire filler metal electrode and the work. Shielding is obtained entirely from an externally supplied inert gas (argon or helium) or reactive gases (C02 o 02) or a combination thereof.The process for using MIG welding is relatively simple: the welder applies an electric arc between a consumable electrode wire and the thin sheet metal, creating a strong bond between the two pieces. Tungsten electrodes. Tungsten electrodes are often used with MIG welding for improved weld strength and esthetic appeal. They provide greater penetration into the metals being .

Although skill requirements are the highest among other welding methods, its advantages truly make TIG welding the king of sheet metal welding. MIG Welding Thin Metals. Gas Metal Arc Welding, or MIG welding, is one of the most straightforward and, therefore, most popular welding methods among beginners. On the contrary, stick welding, also referred to as shielded metal arc welding (SMAW), entails joining metal pieces by melting the filler metal and creating a bond between them. Stick welding is a more generalized process compared to spot welding, which is a localized process. Now, the question arises: Can you use a stick welder for spot welding?

gas arc welding sheet metal

Outside of the hoop profile, and what diameter and gauge of steel the hoops will be, most of the components and features that a large Hoop House is comprised of are straight forward. Snow supports, wind bracing, multiple layers of plastic, attachment hardware, bands and all the rest of it can fairly easily be adapted to whatever type of .

welding sheet metal arc welder|arc welding thin sheet metal