what is cnc machined parts Parts of the CNC Lathe Machine and their functions Let’s look at the major components of a Headstock Different types of CNC Lathe Machines Like the Flat Bed CNC Lathe Machine uses Headstock, which is an important component of CNC Machine that drives the motor and powers the spindle. The front component of a CNC turning machine is made up of .

$22.99

0 · online cnc shop

1 · online cnc machine shop

2 · local cnc machine shops

3 · cnc machining parts usa

4 · cnc machining parts manufacturer

5 · cnc machining custom made parts

6 · cnc machine parts suppliers

7 · cnc machine parts online

$9.99

CNC, or Computer Numerical Control, encompasses the manufacturing process where machines cut, carve and form parts based on computer codes that control the cutting . The choice of material for CNC machined parts depends on factors such as mechanical properties, environmental conditions, and the specific requirements of the application. Some commonly used materials in CNC .CNC machined parts possess numerous advantages over those produced through alternative manufacturing processes. The following section will delve into some of these key benefits. 1. No MOQ. One of the significant benefits of CNC . CNC machining has revolutionized the manufacturing industry, enabling the production of complex parts with unparalleled precision and speed. But what exactly is CNC machining, and how does it work?In this beginner’s guide, we’ll dive into the world of computer-controlled manufacturing and explore its applications, advantages, and future prospects.

Surface Treatment For CNC Machined Parts. Surface treatment for CNC machined parts is a crucial step in the production process. It serves two main purposes: to increase the mechanical properties of the part and to protect it from corrosion.

Parts of the CNC Lathe Machine and their functions Let’s look at the major components of a Headstock Different types of CNC Lathe Machines Like the Flat Bed CNC Lathe Machine uses Headstock, which is an important component of CNC Machine that drives the motor and powers the spindle. The front component of a CNC turning machine is made up of . The machining of parts by CNC machine tools is done automatically according to a pre-programmed program. The operator’s main tasks are program editing, program input, loading and unloading parts, preparing tools, observing the machining status, and inspecting parts, without the need for heavy repetitive manual operations. . Order CNC Machine Parts From Industrial Automation Co. Industrial Automation Co. is the go-to supplier of crucial CNC machine parts like spindle drives and motors, CNC servo drives, and AC servo motors. We understand the vital role that CNC machines play in your operation and provide the service and parts to keep your system running. The result is a finely machined part, embodying the perfect blend of form and function, ready for use in anything from engine parts to medical devices. Types of CNC machining used in parts manufacturing. CNC technology truly shines in its versatility, offering a variety of machining methods, each engineered to cater to specific needs and .

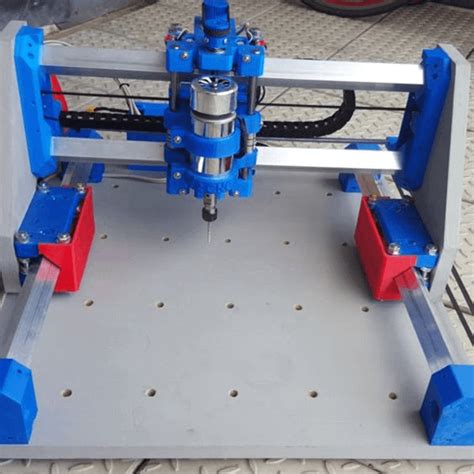

3. CNC (Computer Numeric Control) Computer Numeric Control (CNC) is the automation of machine tools that are operated by precisely programmed commands encoded on a storage medium (computer command module, usually located on the device) as opposed to controlled manually by hand wheels or levers, or mechanically automated by cams alone. In .While 3-axis CNC machining is a highly efficient and versatile technology, it does have some limitations that must be taken into account when selecting a machining method for a particular application. For more complex parts, 4 or 5-axis CNC machining may be a better option. How to Find a High Precision 3-Axis CNC Machining Services ProviderHowever, CNC machining usually comes with a higher price tag, especially with smaller volumes of parts, and has less flexibility with complex geometries, compared to 3D printing. As mentioned previously, CNC machining is a go-to manufacturing process to get precision parts, whether for prototyping or end-use production. What Are the Main Parts of a CNC Machine? 1. Machine Control Unit (MCU) MCU is the core of the CNC machine. They perform all the machine’s controlling functions, including reading the coded instructions, decoding them, and implementing interpolation. 2. Input Devices. The input devices are used to input the program into the CNC machine tools.

seacoast sheet metal

Where Are Machined Parts Used? Part machining provides useful components to just about every industry out there. The high precision of CNC production machining makes CNC machining cost-effective without compromising quality for a wide variety of applications, including:. Aerospace; Automotive; Medical devices; Firearms; Oil and gas; These are just a few of the industries that . The parts of the CNC machines are costly. Maintenance costs are significantly higher in the case of CNC. It does not eliminate the need for costly tools. CNC machine requires skilled programmers. It is not suitable for small-scale production; Maintenance cost is more. 3-Axis CNC machines vs 5-Axis CNC Machines. 3-axis CNC machines were the original standard for machining, able to move and cut across three axes: X, Y, and Z. However, there are some limitations with machining .

Parts of the CNC Lathe Machine and their functions Let’s look at the major components of a CNC Lathe Machine: Headstock Different types of CNC Lathe Machines Like the Flat Bed CNC Lathe Machine uses Headstock, .To elucidate, CNC-machined aluminum parts encompass electronic enclosures, frame extrusions, LED lighting components, mounting brackets, machinery elements, aircraft components, and a broad range of industrial parts. . This article will describe the different parts of a CNC machine. Some parts are common between lathes and mills, like the control unit, driving system, and feedback system, while others are specific to a certain type of machine. For example, tailstocks and headstocks are only found on CNC lathes. 1. Input Device

You rely on CNC machines to make detailed parts like engine components and structural pieces. These machines ensure that each part is made to exact specifications, helping you maintain safety and reliability in aircraft. 3. Automotive: CNC machines are essential in the automotive industry. You use them to create engine parts, transmissions, and .

Machined Metal Parts. Machined Metal Parts is a China CNC precision machining manufacturer and Chinese CNC machining company with state-of-the-art CNC manufacturing factory based in China. We provide Machined Metal Parts, custom 3-5 axis CNC Machining Services, CNC Milling Services, CNC Turning Services, CNC Grinding Services, Wire EDM Machining and .st CNC machined parts will have the material properties of the annealed state. Stress relieving involves the heating of the part to a high temperature (but lower than annealing) and is usually employed after CNC machining, to eliminate the residual stresses created from the manufacturing process. This way parts with more consistent mechanical .Bead blasted CNC machined part. Brushing involves using grit to polish the material in one direction. This process leaves a unidirectional satin finish. Brushing typically provides a CNC machining surface roughness of 1.2 µm Ra and is mainly used for aesthetics. However, this figure may vary with grit size. In simple words, the types of CNC machines used to produce parts are such as a CNC lathe, a 3 axis CNC milling machine, or a 5 axis machining centre. However, the parts’ intricacy will regulate which machine part will be suitable for the job, for example, the intricacy, geometry, and dimensions of parts as well as the tolerances, end-use of .

What are the Parts of a CNC Machine? Bed: Typically constructed from cast iron for enhanced durability and strength, the bed is the machine’s foundation, supporting all components.. Spindle: Inside the machining area, the electrically driven spindle rotates tools that cut and shape the parts. The inside of the spindle is tapered to match the tapered angle of the tool holder to . The international CNC machined parts market is full of opportunities for businesses of all sizes. You must keep yourself updated with changing market demands and showcase your products and expertise in the B2B marketplace to expand .Cnc machinist here, some complicated parts that need things like a 6 axis cnc can take up to 10 hours of programming and setup time, not to mention harder materials like ss require more expensive tools or the machine has to be run slower.

online cnc shop

online cnc machine shop

Roberson Machine Company is a custom manufacturer of precision CNC machined parts. We make it easy to get the custom machined parts you need. Call us today at 573-646-3996 or contact us online. What Materials Can Be Used For Machined Parts? Machined parts can be made from many different materials, including metals and plastics.

sealant for electrical boxes

$85.00

what is cnc machined parts|cnc machine parts suppliers