electric box code.minimum size Box Selection: Choose a junction box with a minimum volume of 22.5 cubic inches. A standard 4x4x2-1/8 inch box typically provides 21 cubic inches, which would be insufficient. Therefore, a larger box, such as a 4x4x2-1/2 inch box .

Correct fill capacity: The junction box should be large enough to contain the wires. .

0 · wiring electrical boxes to code

1 · receptacle box wiring codes

2 · nec 314 for junction box

3 · electrical codes for receptacle boxes

4 · electrical code junction box requirement

5 · electrical code for stapling wire

6 · electrical code for junction boxes

7 · code for electrical box height

Automotive workers must use a variety of welding techniques on the auto’s body to conduct repairs, maintenance, and restoration. They work on fenders, frames, exhausts, automobile panels, and wheels composed of a variety of metals, all of which require experts to employ different types of welders.

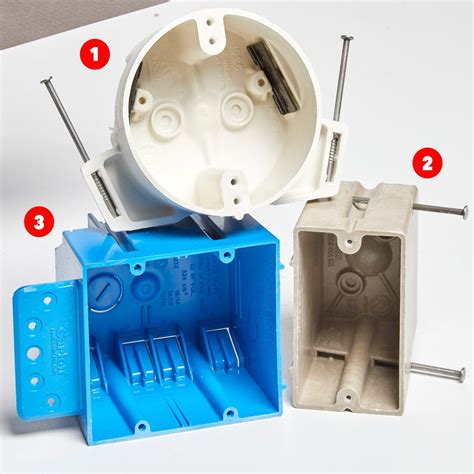

The minimum size box is the smallest one in the Box Fill Table (shown) that can accommodate that number of conductors. No matter how many ground wires, they only count as one conductor in the box. A wire running through the box . You must size pull boxes, junction boxes, and conduit bodies large enough so a crew can install the conductors without damaging them. For conductors 4 AWG and larger, you size pull boxes, junction boxes, and . Installing safe, orderly electrical boxes and cables is made easy by following the recommended electrical codes.Minimum size requirements: Minimum distance from where conductors enter to the opposite wall cannot be less than eight times the trade size of the largest raceway. Straight pulls are when the conduit enters the box on one side, and .

Use this box fill calculator to find the correct size of electrical utility box to fit the conducting wires, grounding wires, and devices or equipment you would need to install and have it pass the National Electrical Code®.Box Selection: Choose a junction box with a minimum volume of 22.5 cubic inches. A standard 4x4x2-1/8 inch box typically provides 21 cubic inches, which would be insufficient. Therefore, a larger box, such as a 4x4x2-1/2 inch box .

Sizing of Junction and pull boxes according to NEC Section 314-28. Today, I will explain Electrical Boxes Volume and Fill Calculations as follows. Part (A), “Box Volume Calculations,” defines the volume of a wiring enclosure or box. The National Electrical Code (NEC) provides guidelines for box sizing based on the number and size of wires you're working with. The NEC specifies the minimum volume of the box in cubic inches (cu. in.) that you . Use 314.28 (A) to size pull boxes, junction boxes, and conduit bodies when using conductor sizes 4 AWG and larger. Suppose you have a 2-inch raceway coming into a 10-inch square box, and a 2-inch raceway leaves .The minimum size box is the smallest one in the Box Fill Table (shown) that can accommodate that number of conductors. No matter how many ground wires, they only count as one conductor in the box. A wire running through the box counts as one wire. Each wire coming into a splice connector is counted as one wire.

You must size pull boxes, junction boxes, and conduit bodies large enough so a crew can install the conductors without damaging them. For conductors 4 AWG and larger, you size pull boxes, junction boxes, and conduit bodies per Sec. 314.28. That means the minimum dimensions of boxes and conduit bodies must comply with the following:

wiring electrical boxes to code

Section 314.16 specifies the minimum volume size of junction boxes required for various types of electrical conductors. The volume size of a junction box is measured in cubic inches. It is determined based on the number and size of conductors within the box. Installing safe, orderly electrical boxes and cables is made easy by following the recommended electrical codes.Minimum size requirements: Minimum distance from where conductors enter to the opposite wall cannot be less than eight times the trade size of the largest raceway. Straight pulls are when the conduit enters the box on one side, and leaves the box on . Use this box fill calculator to find the correct size of electrical utility box to fit the conducting wires, grounding wires, and devices or equipment you would need to install and have it pass the National Electrical Code®.

Box Selection: Choose a junction box with a minimum volume of 22.5 cubic inches. A standard 4x4x2-1/8 inch box typically provides 21 cubic inches, which would be insufficient. Therefore, a larger box, such as a 4x4x2-1/2 inch box with 24 cubic inches, would be appropriate. Compliance: Always ensure that the chosen box meets NEC requirements.

Sizing of Junction and pull boxes according to NEC Section 314-28. Today, I will explain Electrical Boxes Volume and Fill Calculations as follows. Part (A), “Box Volume Calculations,” defines the volume of a wiring enclosure or box.

The National Electrical Code (NEC) provides guidelines for box sizing based on the number and size of wires you're working with. The NEC specifies the minimum volume of the box in cubic inches (cu. in.) that you need to accommodate your wires.

receptacle box wiring codes

nec 314 for junction box

electrical codes for receptacle boxes

Use 314.28 (A) to size pull boxes, junction boxes, and conduit bodies when using conductor sizes 4 AWG and larger. Suppose you have a 2-inch raceway coming into a 10-inch square box, and a 2-inch raceway leaves it on the opposite side.The minimum size box is the smallest one in the Box Fill Table (shown) that can accommodate that number of conductors. No matter how many ground wires, they only count as one conductor in the box. A wire running through the box counts as one wire. Each wire coming into a splice connector is counted as one wire.

You must size pull boxes, junction boxes, and conduit bodies large enough so a crew can install the conductors without damaging them. For conductors 4 AWG and larger, you size pull boxes, junction boxes, and conduit bodies per Sec. 314.28. That means the minimum dimensions of boxes and conduit bodies must comply with the following:

Section 314.16 specifies the minimum volume size of junction boxes required for various types of electrical conductors. The volume size of a junction box is measured in cubic inches. It is determined based on the number and size of conductors within the box.

Installing safe, orderly electrical boxes and cables is made easy by following the recommended electrical codes.Minimum size requirements: Minimum distance from where conductors enter to the opposite wall cannot be less than eight times the trade size of the largest raceway. Straight pulls are when the conduit enters the box on one side, and leaves the box on . Use this box fill calculator to find the correct size of electrical utility box to fit the conducting wires, grounding wires, and devices or equipment you would need to install and have it pass the National Electrical Code®.

Box Selection: Choose a junction box with a minimum volume of 22.5 cubic inches. A standard 4x4x2-1/8 inch box typically provides 21 cubic inches, which would be insufficient. Therefore, a larger box, such as a 4x4x2-1/2 inch box with 24 cubic inches, would be appropriate. Compliance: Always ensure that the chosen box meets NEC requirements.Sizing of Junction and pull boxes according to NEC Section 314-28. Today, I will explain Electrical Boxes Volume and Fill Calculations as follows. Part (A), “Box Volume Calculations,” defines the volume of a wiring enclosure or box. The National Electrical Code (NEC) provides guidelines for box sizing based on the number and size of wires you're working with. The NEC specifies the minimum volume of the box in cubic inches (cu. in.) that you need to accommodate your wires.

durham nc cnc manufacture

dynamic metal fabrication thornton co

Septic System Distribution Box Replacement. Replacing the distribution box costs between $500 and $1,500. This component is also called the D-box. It is very important and is responsible for controlling the even .

electric box code.minimum size|electrical code for stapling wire