sheet metal processing industry Spinning. Stamping. The family of manufacturing processes used to create sheet metal components encompasses a diverse range of techniques, each tailored to achieve specific shapes, sizes, and features with precision and efficiency. You won’t get points on your licence for stopping in a yellow box junction, but the penalty charge can leave a nasty taste in your mouth if you feel it’s unfair. How and where can I appeal?

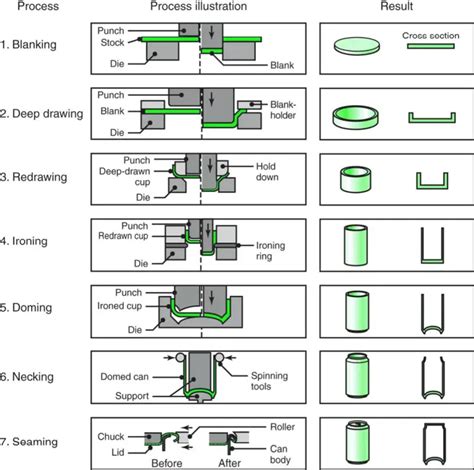

0 · various sheet metal processes

1 · types of sheet metal process

2 · types of sheet metal fabrication

3 · sheet metal process in manufacturing

4 · sheet metal fabrication techniques

5 · sheet metal diagram fabrication

6 · disadvantages of sheet metal

7 · basic sheet metal fabrication techniques

What is the penalty for stopping in a yellow box junction? The fine for stopping in a yellow box ranges from £70 to £130 (the latter in London). However, it is halved if paid within 14 days.

various sheet metal processes

In this article, we’ll explore the nine vital steps in sheet metal fabrication, providing valuable insights for businesses and industry professionals. Keep reading into the fascinating world of .

types of sheet metal process

Sheet metal manufacturing is a fundamental part of modern industry, transforming raw metal into essential components for a wide range of products, from consumer electronics to heavy machinery. This precision . Also known as sheet metal fabrication, sheet metal forming uses metal sheets to make various products and components. The metal sheets are formed and cut into the necessary shape and size via many different .

Spinning. Stamping. The family of manufacturing processes used to create sheet metal components encompasses a diverse range of techniques, each tailored to achieve specific shapes, sizes, and features with precision and efficiency.Sheet metal processing is a method that manipulates flat sheets of metal into desired shapes and structures. Understanding the sheet metal forming process gives us insights into the world of manufacturing, revealing the ingenious .STAHL + TECHNIK is the German-language trade journal for steel production, processing, application technology, innovation and management. The target groups are steel production companies, steel processing companies (from hot .

The metal processing industry, along with machinery production, is amidst Slovenia’s leading exporting sectors and serves as a backbone to the automotive field – the country’s most important export sector. . Thermoplastic injection molding tools, die casting and tools for transforming sheet metal, developed by Slovenian companies are .

China's sheet metal processing industry emphasizes the importance of surface treatment to enhance the final product's aesthetics and durability. Processes like powder coating, electroplating, and anodizing provide corrosion resistance, visual appeal, and surface protection. These surface treatment techniques ensure the longevity and visual . The technological innovations of sheet metal processing industry: The sheet metal processing industry is undergoing technological innovations, including laser cutting, advanced forming technologies, and automated quality control systems. Laser cutting technology is favored for its precision and efficiency, using a high-power laser beam focused .

types of sheet metal fabrication

sheet metal process in manufacturing

traffic bearing junction box

Pasirmas Metal Industry is a new and thriving metal processing company that offers high quality, tailored perforation solutions. Established in 2017, we aim to support the growing demands for perforated sheets across a vast range of industries such as architectural, acoustics, agricultural, food processing, manufacturing and others.

The future belongs to networked manufacturing. For Bystronic, however, the frequently quoted smart factory is just the beginning. The goal is to create an ecosystem that networks sheet metal processing companies with customers, suppliers, and shipping companies. The benefit for everyone involved: greater transparency and efficiency along the entire supply chain.

1.1 Metal cutting-The Sheet Metal Processing Equipment Market refers to the industry that produces and supplies machinery used for shaping, cutting, and forming sheet metal Key players in this . Published By Sheet Metal Industries . July 4, 2024. 2 MIN READ. THREE key considerations when buying a roll bending machine Published By DIMAKIN LTD . October 17, 2024. 4 MIN READ. Choosing High-Quality Sheet Metal Shears in Your Workshop: Factors to Consider Published By DIMAKIN LTD .

Discover the top 10 CAD/CAM software solutions for sheet metal and tube processing. Boost productivity, streamline workflows, and create advanced parts with industry-leading design and manufacturing tools. Find the right fit for your metalworking business.the U.S. metal forming industry will grow by 1.3% in 2023 and 2.2% in 2024. Looking further ahead, First Research projects that industry revenue (in current dollars) will increase at an annual compounded rate of 2.0% from 2023 to 2027. Metal Forming Industry Trends/Drivers Following are several major trends and drivers that are

The press machine is widely used in the sheet metal processing industry and has powerful functions. The press machine can be used for cutting, bending, stamping, forming, and other metal processing. It is necessary to understand the function and use of the press machines before making a choice. Selecting an inappropriate press machine leads to . Contact us. CIDAN Machinery Inc 665 Hwy 74 S #350, Peachtree City, GA 30269, USA Phone: 770-692-7230punching, bending or other processing machines. Thanks to Forstner’s highly advanced technology for sheet straightening, interruption marring is avoided. Automatic material changeover has been standard for decades. The Austrian company Forstner has been making machinery for professional coil handling and sheet metal processing since 1960

The integration of robotics within sheet metal processing has revolutionized manufacturing paradigms. This article explores the cutting-edge applications of robotics in forming, welding, cutting, assembly, and quality assurance processes. It highlights the role of robotics in enhancing precision, minimizing wastage, and ushering in a new era of . Sheet metal processing,Sheet metal working and CNC,Sheet Metal Processing and CNC,Sheet Metal Supplier,Sheet Metal FZ Metalwork Co., Ltd. China Custom Metal Parts Manufacturer with more than 20 years experience. . 20+ years experience of metal parts manufacturing.The accessories we produced are widely used for electronics industry . The precision sheet metal processing industry has high requirements for capital investment and production scale, and customer certification barriers also increase the difficulty of entering high .

Ever since fiber laser technology was introduced into the worldwide sheet metal industry, the sheet metal processing industry has become more developed. With the investment right from the beginning of development, the investors in the . The sheet metal processing industry faces significant challenges due to the volatility of raw material prices, primarily steel and aluminum. Factors such as supply chain disruptions, geopolitical . Unlike financial KPIs that are quite common and readily available, a commonly available set of production KPIs for the sheet metal forming industry is not available. Some available KPIs for manufacturing can provide some guidance for metal formers looking to develop their own. Some examples of useful KPIs can be found in Figure 2.

The sheet metal processing equipment market is a dynamic and rapidly evolving sector, driven by the latest advancements in technology and the increasing demand from a wide range of industries. . Johns Manville and Hercules Industries to learn how sheet metal shop managers and the wider sheet metal industry are scaling up to keep up with this .

Welcome to Michaels Sheet Metal, a leading provider of innovative sheet metal solutions for the construction industry. This article will explore the various sheet metal processing techniques that play a crucial role in construction projects. At Michaels Sheet Metal, we are committed to delivering superior results that meet the unique needs of our clients, leveraging .

Automotive manufacturing relies on significant amounts of metal components that are fabricated from molten metal into large sheet metal sections and down to smaller parts. Processing of these metal components relies on expensive machinery, and the ongoing maintenance of these machines requires significant capital investment.Sheet metal processing is widely used in many industries and has a significant influence on the quality and efficiency of the end product. The costs for processing vary greatly and depend on many factors. These include. Material; Desired quality of the end product; Quantities; Waste & scrapping; Machine and labor costs

In conclusion, China's sheet metal processing industry has established itself as a global powerhouse, offering comprehensive solutions for businesses across sectors. With its advanced technology, versatile applications, and cost-effective advantages, China continues to lead the way in this field. Whether it's automotive, electronics, aerospace .NEUMAIER INDUSTRY: Your partner for integrated automation, automated guided vehicles (AGV), tugger trains, vehicle construction and industrial sheet metal processing. en english. . At the sheet metal processing department of Neumaier we produce sheet metal constructions, welded assemblies and assembly units according to your requirements .K.K. Metal Processing Sdn. Bhd. specializes in the flexible manufacturing of precision sheet metal parts since 1974. We have served the banking, laboratory, printing, furniture, air-conditioning, food processing, power technologies, construction, electrical and electronic, water works and many other industries for over 30 years.

K.K. Metal Processing Sdn. Bhd. specializes in the flexible manufacturing of precision sheet metal parts since 1974. We have served the banking, laboratory, printing, furniture, air-conditioning, food processing, power technologies, construction, electrical and electronic, water works and many other industries for over 30 years.

sheet metal fabrication techniques

sheet metal diagram fabrication

Portable, flexible, rugged, and reliable power distribution center designed to withstand harsh jobsite conditions ; Worksite power distribution requires a 50A 125/250V California Standard twist lock inlet › See more product details

sheet metal processing industry|sheet metal diagram fabrication