sheet metal fabrication shop layout Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. 3D CAD files are converted into machine code, which controls a . Types of Electrical Boxes 1. Junction Boxes. These boxes connect multiple wires and can serve as a point where circuits split or connect. They are essential for safe electrical installations, .

0 · sheet metal shop near me

1 · sheet metal fabricators near me

2 · sheet metal fabricators by state

3 · sheet metal fabrication shops near me prices

4 · sheet metal fabrication shops near me

5 · lowest cheapest sheet metal fabrication

6 · hvac sheet metal fabrication shops near me

7 · fabricating shops near me metal

The drive components are the mechanical components that "drive" the CNC machine along its axis. The most common components associated with a drive system, are the motors, lead or ball screw, or rack and pinions.

sheet metal shop near me

From here, you could scale up by either growing the current layout or duplicating it as another “fabrication module” and dedicating it to a certain range of part geometries or products. Raw stock shelves turn into automated .A well-organized sheet metal fabrication shop layout is crucial for maximizing efficiency, productivity, and safety. By optimizing your shop's layout, you can reduce wasted time and .

d&r electrical cargo box

SMACNA In the Shop focuses on shop operations and provides SMACNA contractors information on shop-specific activities including: fabrication and prefabrication, safety & health, shop layout, technology, and training.Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. 3D CAD files are converted into machine code, which controls a . Classic sheet metal shop layout ideas from an industry expert. The following is taken from the revised second edition of Sheet Metal Shop Layouts, published by Snips in September 1981. Figures used have not been adjusted .

Additionally, optimizing the layout of the shop floor is crucial to reducing material handling and improving overall productivity. By strategically organizing workstations, tools, and materials, employees can easily access . Top 3 Considerations for Metal Fabrication Shop Floor Layout in 2022. Regardless of the products your metal fabrication, HVAC or roofing shop produces, optimizing the shop floor layout can assist in timely order fulfillment .

The following blog post is part three of a multi-part series in which Mestek Machinery discusses the importance of a good shop layout and the ways in which our customers can . A plant’s layout affects how everything flows through the system—raw material, work in process (WIP), personnel, visitors, suppliers, customers, machinery, fixtures, tools, and information. Why Sheet Metal Shop Layout Matters Apr 4, 2018 | by Kirstie Ratzer The following blog post is part three of a multi-part series in which Mestek Machinery discusses the importance of a good shop layout and the ways in which our customers can improve their shops’ productivity by creating an efficient environment for production.

Plan for success when re-designing your metal fabrication or HVAC shop floor layout in 2022. 1-800-665-8089; [email protected]; About. Manufacturers; Careers; Contact; My account; Quotecart (0) . fabrication shop layout | Backed by over 100 years of expertise and experience in metal forming and fabrication, The Mestek Machinery Blog is where HVAC duct and fittings manufacturers and fabricators and other industry professionals can learn more about the technologies and processes that drive your operations. Finding a CAD solution specifically for sheet metal products design is a bit tricky because you'll either need a simple 2D CAD system, or ideally: a parametric or direct 3D modeler that allows you to design flanges and work with bend deductions: In short, a CAD-system with a dedicated sheet metal module.2. Technical requirements of sheet metal workshop - Electrical. Sheet metal workshop has a large load and a lot of equipment. The power supply of the workshop is generally designed according to the cable power supply. In some places, the busway can be reserved. - Gas. Low pressure compressed air is generally used in sheet metal workshop.

2 Formulas For Sheet Metal Layout And Fabrication 2024-05-27 Aviation Administration (FAA) Flight Standards Service. It is intended for use by . You will be introduced to the basic sheet metal shop where you will learn about various methods of forming sheet metal and in some instances even constructing A proper shop layout takes into account the future use of the space a shop has to work with. If a shop needs to make minor adjustments, is it set up so that rearrangements can be made at a minimum cost? 6.) Overall Integration. Merging the first five principles of shop layout is vital to implementing an efficient shop layout into a sheet metal . An HVAC Duct Fabrication Shop makes Rectangular Duct and Fittings that serve as the trunk line on commercial jobs. . While the layout of the machines will vary from shop to shop depending on floor space, it’s typical to position a shop’s sheet metal rack close to the overhead door where the sheet metal is being delivered when received . The sort of math that is needed by those working on the shop floor with sheet metal. So if you dropped out of high school to go to work in construction and sheet metal is your trade, this is the book for you. . If you are looking for sheet metal design, layout or fabrication, look elsewhere. Read more. 30 people found this helpful. Helpful .

While conducting a preplan of a sheet metal shop, you document the building's layout and various use areas, material used, storage arrangements, exits, and fire protection features. The shop has a business office and areas for cutting and welding, metal fabrication, painting, and shipping.Study with Quizlet and memorize flashcards containing terms like When making a sketch of a component what information should be included?, Which layout method is used to develop patterns for rectangular, round, and square ducts?, When constructing an elbow how many gores will reduce air flow resistance the most? and more.Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. 3D CAD files are converted into machine code, which controls a machine to precisely cut a flat pattern, which can be formed into the final

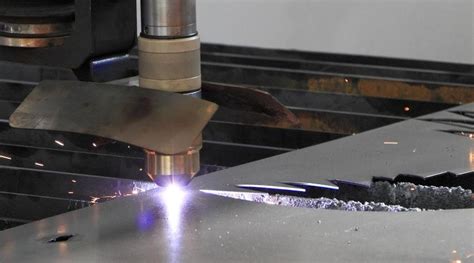

WATCO processes several thousand tons of sheet metal every year. It is brought in and cut to size with a plasma cutter. Bending, welding and roll form is also used in the fabrication process. From estimate to layout to fabrication and installation, WATCO will be On-time and On-budget. This tutorial will show you how to layout a 14/10 to 14/8 transition with the bottom flat and total length will be 12". . 2001 The Sheetmetal Shop. Reproduced with kind permission. . Sheet metal news, fabrication exhibitions, software, cnc, hardware and tutorials. . The big workbench top measures 52" x 120" so there's lots of room for a 4 x 8' sheet of metal. (I use an 8' 18ga. shop break) This has been my main sheet metal bench for many years now.full extension drawers and I designed 4 steel frames with roller balls so you can lay sheet metal on plywood shelves that pull out for acdcess.Material Concepts, Inc. 11620 Caroline Road, Philadelphia, PA 19154-2116 Phone: 215-338-6515 | Toll Free: 800-372-3366 [email protected]

The Importance of Good Shop Layout By Richard S. Budzik originally appeared in SNIPS Magazine.. Basically, a shop layout is a floor plan showing all the machinery, equipment and materials needed, beginning with . Snips News Sheet Metal Fabrication Shop Layout Tips to keep your sheet metal shop OSHA compliant. By Emell Derra Adolphus. December 7, 2018. Safety is a skill. And like any skill, it takes practice to perfect. As a company, this should be your first priority. “When employees feel like their employer is willing to take care of them and do .Metal shop. Introducing a new machine to your shop can disrupt your existing workflows and create unanticipated issues with your team. Mac-Tech can help; we can create a metal shop floor plan that positions your equipment for optimal efficiency and workflow, while also ensuring your team has a safe work environment and enough space to operate without interference.Get an overview to sheet metal fabrication from the different types of sheet metal fabrication, to design best practices, materials, finishings and fastenings. 20% off your first order. Save up to ,000/€1,000. Ends 30 Nov 2024. Get a quote. Help center. EN.

Metal Fabrication: A Practical Guide 4th Edition. Special Price 3.45 Regular Price 4.95. Quickview. Add to Cart. Add to Wish List Add to Compare. Precision Sheet Metal Shop Practice. Special Price .95 Regular Price .95. Quickview. Add to Cart. Add to Wish List Add to Compare. Precision Sheet Metal Blueprint Reading 3rd Edition . In this video, you will see me explaining the basic steps required to measure and mark out on sheet metal in. These steps are transferable through any sheet .

This shop by McCorvey Sheet Metal Works will give you an idea of what a large sheet metal fabrication shop entails. Most fabrication shops will not be this large, but this will give you an idea of what is capable on a larger scale and how productivity is also related to how well a shop is organized and professionally operated. Basically, a shop layout is a floor plan showing all the machinery, equipment and materials needed, beginning with the receipt of the raw materials (sheet metal and other items) and progressing to the shipment of the completed products (pipe, fittings and miscellaneous sheet metal items). The best shop layout permits the quickest flow of .

Danforth’s state-of-the-art Sheet Metal Fabrication Shop and skilled workforce is capable of manufacturing and installing a wide array of fabricated sheet metal products. Our Sheet Metal Team is equipped to produce high quality metal products from light gauge HVAC ductwork to heavy gauge industrial duct systems.Sheet Metal 1 Learn with flashcards, games, and more — for free. . The Joint Apprenticeship and Training Committee determines the number of apprentices employed by a particular shop. True. . sheet metal workers and employers. A variety of career options are available in the sheet metal trade. True. Sheet metal fabrication involves cutting . Fabrication: CNC Laser, Waterjet, Plasma, Welding . Ideas for fab shop layout, sheet storage? Thread starter El Mustachio; Start date Nov 12, 2011; Replies 10 Views . See: Sheet racks Roll-out sheet racks and rack systems for storing sheet metal and flat steel products. Roll-out design is superior to cantilevered racks and rack systems and .

sheet metal fabricators near me

sheet metal fabricators by state

cylinder end cap cnc precision machining manufacturer

sheet metal fabrication shops near me prices

Learn about the many common types of wall and ceiling electrical boxes for switches, outlets, light fixtures, ceiling fans, and junction boxes.

sheet metal fabrication shop layout|hvac sheet metal fabrication shops near me