benefits of using cnc machines for batch production Using CNC machines for batch production can streamline the workflow because of the reliability, accuracy, and speed of CNC-based manufacturing. The Benefits. CNC machining offers immediate cost savings because of the accuracy and low waste of raw materials. Grand Forks Welding’s Men of Steel will fabricate new items and repair and improve existing designs. Additionally, our fully stocked parts department eliminates your down time and builds up time. Over the years, Grand Forks Welding has acquired a reputation for doing the highest quality work and giving the best possible service.

0 · cnc manufacturing process

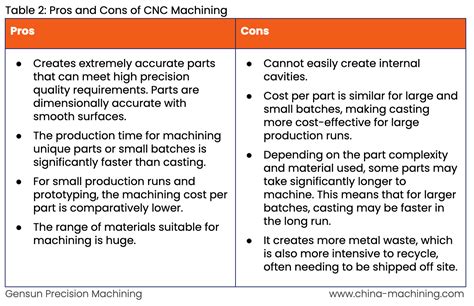

1 · cnc machining pros and cons

2 · advantages of cnc machining

3 · advantages and disadvantages of cnc

In this blog post, we will explore the key factors that affect MIG welding sheet metal, including wire size, gas selection, amperage, and voltage. We will also provide tips and best practices to help you achieve optimal .

cnc manufacturing process

Using CNC machines for batch production can streamline the workflow because of the reliability, accuracy, and speed of CNC-based manufacturing. The Benefits. CNC machining offers immediate cost savings because of the accuracy and low waste of raw materials.29. Create a Peck Drilling Program in Circular or Rectangular Patterns Using .The first CNC machines—or NC machines as they did not require a computer back .

Explore the advantages and applications of small batch CNC machining, including production flexibility, product variability, and cost-effectiveness. This article delves into how CNC machining efficiently supports small batch production, adapting .

Whether for small batches or mass production, CNC machines offer a faster and more efficient production process, making them indispensable in the manufacturing industry. CNC machining shines when it comes to creating .

Some of the expected benefits of the production CNC machining process include: High Profitability. CNC machines are famous for their continuous, repeatable machining operations capabilities, contributing . Small batch CNC machining offers numerous advantages: greater flexibility, reduced inventory costs, easier customization, rapid prototyping, and superior precision. These benefits can lead to substantial cost savings and . Discover the advantages of utilizing rapid CNC for small-batch production. From versatility and precision to cost-effectiveness and customization, learn why CNC machining is .

The advantages of CNC machining make it a go-to solution for industries needing high precision, efficiency, material versatility, and customization. At MakerVerse, we offer a wide range of .

CNC machining is a highly efficient manufacturing process, significantly reducing waste and production costs. This is achieved through the use of computer-controlled machines that . Small batch CNC machining involves small-scale production of products or components, typically between 10-1000. Small batch CNC machining has emerged as a pivotal strategy, offering a myriad of benefits and employing .

CNC milling streamlines the process from prototyping to production with high-level precision, versatility, and efficiency for various applications. This article illuminates the top benefits that render CNC milling an indispensable tool in the . Using CNC machines for batch production can streamline the workflow because of the reliability, accuracy, and speed of CNC-based manufacturing. The Benefits. CNC machining offers immediate cost savings because of the accuracy and low waste of raw materials.Explore the advantages and applications of small batch CNC machining, including production flexibility, product variability, and cost-effectiveness. This article delves into how CNC machining efficiently supports small batch production, adapting to rapidly changing market demands. Whether for small batches or mass production, CNC machines offer a faster and more efficient production process, making them indispensable in the manufacturing industry. CNC machining shines when it comes to creating complex designs.

Some of the expected benefits of the production CNC machining process include: High Profitability. CNC machines are famous for their continuous, repeatable machining operations capabilities, contributing significantly to increased throughput. Small batch CNC machining offers numerous advantages: greater flexibility, reduced inventory costs, easier customization, rapid prototyping, and superior precision. These benefits can lead to substantial cost savings and elevated customer satisfaction levels, making small batch CNC machining an attractive option for many businesses.

cnc machining pros and cons

Discover the advantages of utilizing rapid CNC for small-batch production. From versatility and precision to cost-effectiveness and customization, learn why CNC machining is a game-changer in manufacturing.The advantages of CNC machining make it a go-to solution for industries needing high precision, efficiency, material versatility, and customization. At MakerVerse, we offer a wide range of CNC machining services tailored to meet your project’s unique requirements.CNC machining is a highly efficient manufacturing process, significantly reducing waste and production costs. This is achieved through the use of computer-controlled machines that enhance product precision, improve efficiency, boost profit margins, and increase overall market competitiveness. Small batch CNC machining involves small-scale production of products or components, typically between 10-1000. Small batch CNC machining has emerged as a pivotal strategy, offering a myriad of benefits and employing specialized techniques to cater to the demands of diverse industries.

CNC milling streamlines the process from prototyping to production with high-level precision, versatility, and efficiency for various applications. This article illuminates the top benefits that render CNC milling an indispensable tool in the engineer’s arsenal.

Using CNC machines for batch production can streamline the workflow because of the reliability, accuracy, and speed of CNC-based manufacturing. The Benefits. CNC machining offers immediate cost savings because of the accuracy and low waste of raw materials.Explore the advantages and applications of small batch CNC machining, including production flexibility, product variability, and cost-effectiveness. This article delves into how CNC machining efficiently supports small batch production, adapting to rapidly changing market demands. Whether for small batches or mass production, CNC machines offer a faster and more efficient production process, making them indispensable in the manufacturing industry. CNC machining shines when it comes to creating complex designs. Some of the expected benefits of the production CNC machining process include: High Profitability. CNC machines are famous for their continuous, repeatable machining operations capabilities, contributing significantly to increased throughput.

Small batch CNC machining offers numerous advantages: greater flexibility, reduced inventory costs, easier customization, rapid prototyping, and superior precision. These benefits can lead to substantial cost savings and elevated customer satisfaction levels, making small batch CNC machining an attractive option for many businesses. Discover the advantages of utilizing rapid CNC for small-batch production. From versatility and precision to cost-effectiveness and customization, learn why CNC machining is a game-changer in manufacturing.

The advantages of CNC machining make it a go-to solution for industries needing high precision, efficiency, material versatility, and customization. At MakerVerse, we offer a wide range of CNC machining services tailored to meet your project’s unique requirements.CNC machining is a highly efficient manufacturing process, significantly reducing waste and production costs. This is achieved through the use of computer-controlled machines that enhance product precision, improve efficiency, boost profit margins, and increase overall market competitiveness. Small batch CNC machining involves small-scale production of products or components, typically between 10-1000. Small batch CNC machining has emerged as a pivotal strategy, offering a myriad of benefits and employing specialized techniques to cater to the demands of diverse industries.

Stick welding sheet metal can be done by welding DC electrode negative with 20-40A which is about the the lowest amperage settings that still allows to strike an arc. Suitable electrodes are E6011 for rusty or painted surfaces or E6013 for clean surfaces.

benefits of using cnc machines for batch production|advantages of cnc machining