3 axis cnc turning machine Our VTM-100 3-axis vertical turning center combines the benefits of a vertical lathe with those of a machining center. The 50-taper 36-tool magazine enables this machine to offer both turning and milling operations on a single platform. By understanding the function of junction boxes, using the right tools and materials, following a step-by-step guide, and avoiding common mistakes, DIY enthusiasts can tackle wiring projects with confidence.

0 · small 3 axis cnc mill

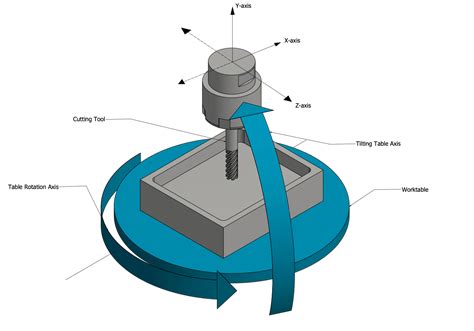

1 · axis identification in cnc machine

2 · 3 axis vs 5 mill

3 · 3 axis vertical milling machine

4 · 3 axis hobby milling machine

5 · 3 axis cnc milling machine

6 · 3 axis cnc machine price

7 · 2.5 axis milling vs 3

In this article series about septic system drop boxes we describe the best procedures for locating and inspecting, repairing or replacing the septic drainfield distribution box, or the "D-box" or "Splitter box".

Our VTM-100 3-axis vertical turning center combines the benefits of a vertical lathe with those of a machining center. The 50-taper 36-tool magazine enables this machine to offer both turning and milling operations on a single platform.

Haas turning centers offer a wide range of capabilities, including toolroom lathes, big-bore versions, dual-spindle models, live tooling with C-axis, and Y-axis capability.Our VTM-100 3-axis vertical turning center combines the benefits of a vertical lathe with those of a machining center. The 50-taper 36-tool magazine enables this machine to offer both turning and milling operations on a single platform.

Haas turning centers offer a wide range of capabilities, including toolroom lathes, big-bore versions, dual-spindle models, live tooling with C-axis, and Y-axis capability.The DS-30Y Y- axis turning center combines dual-spindle turning with Y axis, C axis, and live tooling to create a powerful “done-in-one” machining solution for any shop. . BC3751-H is a high-performance and multifunctional turning center.

Sometimes referred to as a 3 axis lathe due to the programmable C axis in the main spindle, (X, Z, & C), has driven tools in the turret to perform milling & drilling functions while the workpiece remains stationary or in slow motion, called C-axis contouring or indexing.A Versatile Lineup of Vertical Machining Centers (VMC) - Whether you need a standard 3-axis mill, a powerful 5-axis machining center, or a small VMC for precision parts, there’s a Haas to do the work.3-Axis CNC Machining. 3-axis CNC machining evolved from rotary filing (think dental drill 😬). With a 3-axis CNC machine, the workpiece is stationary while the cutting tool moves across the X-, Y-, and Z-axes.Milling machines are designed for 3-axis machining in their simplest form: The tool moves over the workpiece in the X, Y and Z directions. For example, A rotary axis in the headstock or table expands the machining spectrum because components can also be placed at an angle.

For 3-axis turning applications, the Tornado MillTurn CNC turning centres are the perfect machine, with full c-axis spindle control, spindle disc brake and driven tooling making radial and axial milling, drilling, boring and tapping machining processes easier than ever.

Experience advanced 3-axis lathes at Think CNC. Engineered for complex, precision turning. Elevate your machining capabilities today! 3-Axis vs. 5-Axis: Pros and Cons. The main difference between these two types of CNC machines is the number of ways they can move their tool: one has three, and one has five. This seemingly small factor, however, makes a world of difference, as you can see in the side-by-side comparison table below.Our VTM-100 3-axis vertical turning center combines the benefits of a vertical lathe with those of a machining center. The 50-taper 36-tool magazine enables this machine to offer both turning and milling operations on a single platform.

Haas turning centers offer a wide range of capabilities, including toolroom lathes, big-bore versions, dual-spindle models, live tooling with C-axis, and Y-axis capability.

The DS-30Y Y- axis turning center combines dual-spindle turning with Y axis, C axis, and live tooling to create a powerful “done-in-one” machining solution for any shop. . BC3751-H is a high-performance and multifunctional turning center.Sometimes referred to as a 3 axis lathe due to the programmable C axis in the main spindle, (X, Z, & C), has driven tools in the turret to perform milling & drilling functions while the workpiece remains stationary or in slow motion, called C-axis contouring or indexing.A Versatile Lineup of Vertical Machining Centers (VMC) - Whether you need a standard 3-axis mill, a powerful 5-axis machining center, or a small VMC for precision parts, there’s a Haas to do the work.3-Axis CNC Machining. 3-axis CNC machining evolved from rotary filing (think dental drill 😬). With a 3-axis CNC machine, the workpiece is stationary while the cutting tool moves across the X-, Y-, and Z-axes.

Milling machines are designed for 3-axis machining in their simplest form: The tool moves over the workpiece in the X, Y and Z directions. For example, A rotary axis in the headstock or table expands the machining spectrum because components can also be placed at an angle.For 3-axis turning applications, the Tornado MillTurn CNC turning centres are the perfect machine, with full c-axis spindle control, spindle disc brake and driven tooling making radial and axial milling, drilling, boring and tapping machining processes easier than ever.Experience advanced 3-axis lathes at Think CNC. Engineered for complex, precision turning. Elevate your machining capabilities today!

2017 leaf metal perfect game all american baseball hobby box

small 3 axis cnc mill

You should consider using a metal electrical box if: You use metal-sheathed BX cable. Metal-sheathed cable is designed to be used with a metal junction box to ground the wires (although you may still be required to use a ground wire of some type). It’s extremely important the electrical box is securely attached to a stud (rather than being .

3 axis cnc turning machine|3 axis cnc machine price