cnc machine tested Quality testing and inspection in CNC machining applications represent a critical phase, ensuring every machined component meets the high standards of precision and excellence. This article dives into the intricate world . This V-groove wheel box has a bare finish. It will fit our 3" and 4" V-groove wheel. Choose our all solid steel V-groove or solid nylon V-Groove gate wheels for attaching to square stock and horizontal rails of sliding gates. Near axle and shaft secure wheel to all steel heavy duty box.

0 · free cnc machinist assessment test

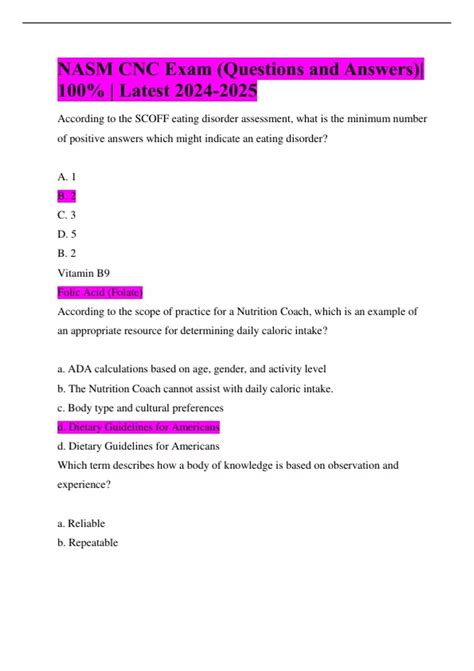

1 · cnc test questions and answers

2 · cnc practice test

3 · cnc machinist test pdf

4 · cnc machining test basic questions

5 · cnc free test exams

6 · cnc certification test

7 · cnc 1st year mock test

Features: 158 x 90 x 60mm size, Surface Mounted, sealed plastic electrical enclosure switch Junction box. Better Anti-corrosion performance; protect your instruments even under the adverse environment. Certain modification can be done according to your requirments; such as drilling, painting, punching, silk-screen printing and etc.Suitable for airport, subway station, button box, small terminal, signal chassis, sensor, measuring device, communication junction box and .

Quality testing and inspection in CNC machining applications represent a critical phase, ensuring every machined component meets the high standards of precision and excellence. This article dives into the intricate world .A CNC machine is a powerful tool for automating complex and precise tasks, such as cutting, shaping, or milling materials. These machines have revolutionized manufacturing by filling .

Inspections and testing are essential for ensuring quality control in CNC machining. Quality assurance teams use a variety of methods, such as visual inspections to examine the surface . Explore quality control and inspection technologies for CNC machined parts. Learn how to use different measurement tools to ensure quality in CNC machining.The ballbar test has gained popularity due to its simplicity, speed of use, and ability to generate large amounts of quantitative data to measure machine tool accuracy.

Understanding CNC Machine Accuracy and Repeatability. Properly evaluating machine tool capability requires understanding how the both user and the builder can influence precision. I define a CNC machine tool’s accuracy as . The use of static processes to control and manage CNC machines while working helps manufacturers determine if there are any deviations or errors, which ensures a high-quality CNC machined part. Using Qualis 4.0, SPC .

10000+ "cnc test" printable 3D Models. Every Day new 3D Models from all over the World. Click to find the best Results for cnc test Models for your 3D Printer.

About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy & Safety How YouTube works Test new features NFL Sunday Ticket Press Copyright . Jinan Yaoneng Machinery Technology Co.,Ltd Wechat /Whatsapp/Mobile: + 86 13370575016 Email: [email protected] site: www.yaonenglaser.com Alibaba : htt.What is Quality Testing and Inspection in CNC Machining Applications? 12 MinWhat is Quality Testing and Inspection in CNC Machining Applications? Quality testing and inspection in CNC machining are processes dedicated to verifying that the output meets specific standards of accuracy and integrity.

CNC Test - Form STM. SKU RR198. Starting from .00. Format: 60 items, Multiple-choice. Assesses: CNC knowledge. Skill Level: Journey-level. Language: . Set up and operate a variety of machine tools to produce precision parts and instruments. Includes precision instrument makers who fabricate, modify, or repair mechanical instruments. .

Welcome to our blog post on a comprehensive CNC machine inspection checklist! CNC machines play a crucial role in modern manufacturing, enabling precision and efficiency in various industries. However, like any machinery, CNC machines require regular inspection and maintenance to ensure optimal performance and safety. CNC machines are modern subtractive manufacturing equipment, which automatically control the tool path and movement for material removal. You can find different types of CNC machines in industrial factories and the CNC Machine Shop, each with specific manufacturing purposes.However, all of them are used to craft the blank work material into the .CNC CAD Machine Test Engineer jobs. Sort by: relevance - date. 200+ jobs. Senior CNC Programmer. Kalman Manufacuring - CNC Precision Machining 3.6. Morgan Hill, CA 95037. 0,000 - 0,000 a year. Full-time. Monday to Friday +2. Easily apply. THIS FILE IS FOR ELITE SERIES (Masso) Machines ONLY! Did you know that the Team Onefinity sign that came with your CNC was actually cut by your machine? That’s not just for style points. Every CNC we make is fully assembled, tested, and checked for quality before leaving our facility. The g-code that comes pre-loaded is what we use to make sure .

Take our CNC machinist test. The thirty-question test features questions in several areas. These include power and pneumatic tools, steam generation equipment, safety and housekeeping procedures, disassembly and reassembly, machine tools and shop procedures, and gauges and measuring instruments.

Cylinder head porting, flow bench testing and custom hand porting at our full service machine shop. Remove CNC step lines and unwanted airflow turbulence. 865-429-3172 [email protected]. . Owners of CNC ported heads, many companies do not remove the step lines left in the ports from CNC machining, this causes slight .Functionality Testing: Ensure the part performs as intended in its application. CNC Machining Services at SINO MFG. . CNC machining is a cornerstone of modern manufacturing, offering precision, efficiency, and versatility. By following the step-by-step process outlined above, manufacturers can ensure high-quality and consistent results. . So buckle up and get ready to discover the endless possibilities with the Genmitsu Cnc Router Machine 4040-Pro. I Tested The Genmitsu Cnc Router Machine 4040-Pro Myself And Provided Honest Recommendations Below. PRODUCT IMAGE. PRODUCT NAME. RATING. ACTION. PRODUCT IMAGE. 1. PRODUCT NAME.

Spindle test bars are a quick and easy way to verify the runout and alignment of your machine’s spindle after a crash, after the machine has been moved, or as a periodic performance check. Excessive runout and axial play in a machine tool .

This work suggests an innovating method of testing the accuracy of a CNC machine tool by using the “calliper”, with a view to enhancing the positioning accuracy of the feed kinematic linkages .

In this article, I’ll be sharing my experience with the Genmitsu Cnc Router Machine 4040-Pro, its features, and why it’s a must-have for any DIY enthusiast or professional woodworker. So, let’s dive in and explore this . Custom CNC machining features some of the most technologically advanced equipment and cutting-edge robotic technology. It is programmed using G-code and M-code, which facilitates accurate, repeatable manufacturing of parts. Besides, specific components demand strict spec tolerances, all of which are achievable using a custom CNC machining .Following pre-spin testing, components are semi-finish machined to create the near-final shape. Semi-finish machining is a more precise version of rough machining with typical tolerances of +/- 0.005 in. (0.127 mm) and it leaves behind approximately 0.050 in. (1.27 mm) of material on all touched surfaces.

Michael, We feel that Ball-bar and Laser calibration are crutial when purchasing a used machine. The last used machine that I bought was a 4020 Fadal and it ran ,800 to have it tested in Souther Cal. A CNC machine is an automatic power tool with computer controlled for turning, milling, engraving, cutting, drilling, grinding, welding, spinning, winding in modern industrial manufacturing. . and the testing room is 20 degrees +-2 degrees. The assembly workshop is also air-conditioned to reduce temperature fluctuations. The assembly process .Study with Quizlet and memorize flashcards containing terms like Indication of Surface Texture Basic Symbol, Allowance for a specific variation in the size and geometry of part, If removal of material by machining is required and more.

In CNC machining, selecting the appropriate hardness testing method depends on factors such as the material type, surface condition, and desired level of accuracy. By understanding the principles and applications of these common hardness testing methods, you can ensure the quality and performance of their machined parts.CNC Accuracy Test Testing your CNC's accuracy. Test Procedure. The test procedure is simple. Back the machine up against the indicator fully depressing it then back it out about 1/32", Zero the meter then run it out a full 1". Why Quality Control is Important in CNC Machining. CNC (Computer Numerical Control) machining is a process that involves the use of computers to control machine tools. These machines are highly accurate and capable of creating complex parts with tight tolerances. . Material certificates and documentation should be cross-checked, and material .

free cnc machinist assessment test

Test Tool: 1/2 diam x 1.25" loc 3 flute, finish endmill 1.50" extension from tool holder 1) Accupro 37 degree helix Zrn coating manf# 65250193 . CNC Machining. ABOUT PRACTICAL MACHINIST. With more than 10.6 million unique visitors over the last year, Practical Machinist is the most visited site for metalworking professionals. Practical .

Simple CNC MILL test part. Thread starter claya; Start date Nov 16, 2018; Replies 5 Views 5,001 C. claya Cast Iron. Joined Aug 6, 2006 Location california. Nov 16, 2018 #1 Anyone have a favorite simple test part for cutting on a "for sale" used machine? . CNC Machining. ABOUT PRACTICAL MACHINIST.

industrial metal fabricator poland

industrias metalmecanicas de mexico directorio

model: mnt-hk02 | color: black UTG H&K STANAG Steel Claw Mount. UTG 2nd generation H&K STANAG steel claw mount complete with picatinny rail for solid mounting of optics.

cnc machine tested|cnc machining test basic questions