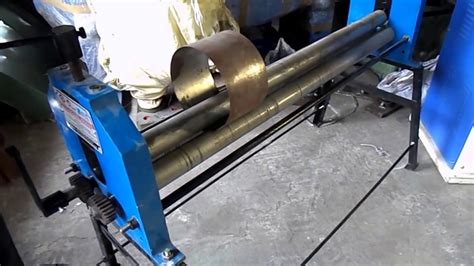

roller bending sheet metal Create bends, curves, and circles in sheet metal. Also known as slip rolls, these curvers can form a single curve. The rollers also have wire grooves to shape three sizes of wire. Coming from the hardcore 4x4 world full of people with dedicated trailered wheeling rigs, I say get some 1/8" steel, and box away! Frame flex is a BAD thing. Know though, that in doing it, your rig may feel more rigid (a good thing), and your suspension will do what it is meant to do, instead of the frame.

0 · types of sheet metal rollers

1 · stainless steel sheet bending machine

2 · sheet metal edge shaping rollers

3 · manual sheet metal rollers

4 · heavy duty sheet metal roller

5 · hand held sheet metal roller

6 · 3 cylinder sheet metal rollers

7 · 10 gauge sheet metal roller

However, one unassuming but often overlooked component is green metal boxes in yards, usually placed near homes and buildings. Pad-mount transformer boxes, commonly recognized as those little green boxes, are an integral part of .

Create bends, curves, and circles in sheet metal. Also known as slip rolls, these curvers can form a single curve. The rollers also have wire grooves to shape three sizes of wire.

big box distribution center

This is where roll bending comes in. Roll bending is a highly effective technique for creating smooth, consistent curves in sheet metal and other materials. Using a series of rollers; you .This Komaspec guide provides an overview of the main sheet metal bending processes, the advantages and disadvantages of each, basic design considerations with sheet metal bending . The Roll Forming Machine, also known as the Plate Rolling Machine or Sheet Metal Roller, is a versatile metal forming equipment used to .

Roll bending, also known as plate rolling or angle bending, is a metalworking process that uses a series of rollers to bend a metal piece into a specific curve or radius. The metal is forced through the rollers, progressively . Sheet Metal Bead Roller Machine, Rotary Steel Bending Bender, Sheet Metal Bead Roller Bending Machine Set, with 6 Dies Set, 1.2mm Sheet Metal Bead Roller Rotary Burring Swaging Machine. Share: Found a lower price? Let us know. Although we can't match every price reported, we'll use your feedback to ensure that our prices remain competitive. VEVOR Slip Roll Machine, 24 inches Forming Width in 16 Gauge Capacity, Sheet Metal Slip Roller Rolling Bending Machine, with 2 Detachable Rollers for Low Carbon Steel Copper Sheet Aluminum Alloy Sheet.

VEVOR Slip Roll Machine, 12.6 inches Forming Width in 20 Gauge Capacity, Sheet Metal Slip Roller Rolling Bending Machine, with 2 Detachable Rollers for Low Carbon Steel Copper Aluminum Alloy Sheet . Visit the VEVOR .

The item is a 3 station edge roller bender roofing sheet metal bending tool. It is used to bend metal plates within the range of 0-90 degrees with a recommended folding height of 13-130mm. It is designed for bending metal roof materials such as steel, aluminum, and copper. The 3 station roller design ensures stable and uniform bending without .

During roll bending, the sheet metal undergoes equivalent deformation to free bending. The curvature of the roll-bent part is determined by the position of the rollers, the thickness of the sheet metal, and its mechanical properties. . During heat bending, the sheet metal should be heated to 950 to 1100 ℃, with uniform heating and rapid .

Edge Roller Bending Roofing Sheet Metal Bender Hand Tool at 0-90° Angle, Three-Station Sheet Metal Roller Bender Making 5/8" to 4" (16 to 102 mm), for 29 to 22 Gauge Steel. 4.99 $ 134. 99. Typical: 2.99 2.99. 5% off coupon applied Save . Mophorn 12.6 in. Slip Roll Roller Metal Plate Bending Round Machine, Slip Roll Machine Up to 22 Gauge Steel, Sheet Metal Roller, Slip Rolling Bending Machine with Two Removable Rollers . Visit the VEVOR Store. 3.5 3.5 out .Bonbo ER3 Three-Station Edge Roller Bender,Large Radius Sheet Metal Bead Roller Bender,0-90° Bending Angle, for 29 to 22-Gauge Steel,Making 5/8" to 4" (16 to 102 mm) Bends. 1.99 $ 131. 99. FREE delivery Tue, Nov 12 . Or fastest delivery Tomorrow, Nov 8 . Only 15 left in stock - .

Three-Station Edge Roller Bender,0-90° Bending Angle Bending Metal Roofing Materials,Adjustable for Making 5/8" to 4" (16 to 102 MM) Bends in 29 to 22-Gauge Steel,Large Sheet Metal Bender 4.2 out of 5 stars 22With a single tool, create both sharp creases and soft curves along the edges of sheet metal. Also known as edge rollers, these tools slide back and forth along edges to create even bends. Unlike benchtop sheet metal tools, these shapers are portable, so they’re often used on-site by roofers. Use 1/8 ” markings to set up precise bends.

3 roll and 4 roll Sheet metal and plate bending roll machines from American Machine Tools Corporation. PLATE ROLLS . Roll Benders . Interested in curving your sheet metal or plate? We have 3 roll and 4 roll benders that work by pinching the metal between the top and bottom rolls and curving it as it comes in contact with a back forming roll. . Three-Station Edge Roller Bender,0-90° Bending Angle Bending Metal Roofing Materials,Adjustable for Making 5/8" to 4" (16 to 102 MM) Bends in 29 to 22-Gauge Steel,Large Sheet Metal Bender 4.2 out of 5 stars 22 Metal Bead Roller with 12 Dies, Sheet Metal Bead Roller Machine 19'' Sheet Metal Bead Bending Roller Rotary Forming Machine, 1/16" 1/8" 1/4" Step Dies, 1/4" 3/8" 1/2" Bead Dies. Share: Found a lower price? Let us know. Although we can't match every price reported, we'll use your feedback to ensure that our prices remain competitive. The item is a 3 station edge roller bender roofing sheet metal bending tool. It is used to bend metal plates within the range of 0-90 degrees with a recommended folding height of 13-130mm. It is designed for bending metal roof materials such as steel, aluminum, and copper. The 3 station roller design ensures stable and uniform bending without .

* Sheet metal bender - The manual roll bender adopts a new design, the structure is simple but very practical. As a hand tool that can easily bend various metal materials into a round shape, it does not consume .

Sheet Metal Bead Roller Machine, Rotary Steel Bending Bender, Sheet Metal Bead Roller Bending Machine Set, with 6 Dies Set, 1.2mm Sheet Metal Bead Roller Rotary Burring Swaging Machine. 5.0 out of 5 stars. 2. 5.00 $ 155. 00. 6% off coupon applied Save 6% with coupon. delivery Nov 14 - 19 .

types of sheet metal rollers

VEVOR 12.6 in. Slip Roll Roller Metal Plate Bending Round Machine, Slip Roll Machine Up to 22 Gauge Steel, Sheet Metal Roller, Slip Rolling Bending Machine with Two Removable Rollers . Visit the VEVOR . VEVOR Slip Roll Machine, 24 inches Forming Width in 16 Gauge Capacity, Sheet Metal Slip Roller Rolling Bending Machine, with 2 Detachable Rollers for Low Carbon Steel Copper Sheet Aluminum Alloy Sheet - Amazon.comEdge Roller Bending Roofing Sheet Metal Bender Hand Tool at 0-90° Angle, Three-Station Sheet Metal Roller Bender Making 5/8" to 4" (16 to 102 mm), for 29 to 22 Gauge Steel. 4.99 $ 134. 99. Typical: 2.99 2.99. 5% off coupon applied Save .

Save space in your shop by cutting, bending, and curving sheet metal with a single machine. Also known as shear brake rolls. Use the blade on the shear to make clean, straight cuts; it has two cutting edges for twice the life. A press brake makes bends up to 90°. Create curves and circles with the slip roll.. When using the shear or press brake, set the manual back gauge to . Three Station Roller, Roofing Sheet Metal Bender at 0-90 Angle, Metal Bending Tool for Bending 0.01‑0.04 Inch (0.3‑1.0mm) and Folding Height of 1/2‑5 Inch (13‑130mm) 4.1 out of 5 stars 8 2 offers from 999 $ 149 99 Types of Sheet Metal Rolling Machines. Sheet metal rolling machines come in various types to suit different applications. 1. Three-Roller Bending Rolls: These machines employ three rolls to bend metal sheets, offering precise control and versatility. 2. Four-Roller Bending Rolls: Incorporating an additional support roll, these machines provide . Roller Bender, Three Station Roller for Bending Metal Sheet Metal Roller Bender Professional Edition Metal Bending Tool, Paint Rollers. 1 offer from 2.79. Ring Roller Bender 3", Manual Ring Roller Bender up to 1/4" Round Steel & 1" x 3/16" Flat Steel, Steel Portable Hand Crank Ring Roller 13-1/2'' Long Handle.

Roll bending, otherwise known as roll forming, is a continuous bending operation in which a long strip of sheet metal or a tube is molded to get a desired curvature. Roll forming is intended for producing constant profile parts with long lengths and in production quantities.

Bends up to 1 1/4" of Sheet Metal From 90° to 180° - Ideal for Hems The Wuko Bender 4040 is an ideal tool to create hems. It features a thin bending wheel, which allows for bends from 90° up to 180°.Another great tool from the Wuko Arsenal.Wuko benders are a must have tools for metal roofers, those bending metal without a brake / box brake and those making radius roof panels .Portability – Don’t need to bend at the shop, can bend metal on the job; Bending Depths – make bends from 3/8″ to 14″ depending on the item; No Limit to Length of Bend – A 10′ brake can bend 10 ft max, no max bend with edge rollers; Bend Past 90° – New model benders allow you to bend past 90° without scratching the material

In understanding sheet metal bending, this article introduced how to bend sheet metal and other things ideal for effective execution. Capabilities. CNC Machining. . The metal sheet is fed between the upper roller and the two fixed rollers. As the two fixed rollers rotate, they grip the sheet, while the adjustable roller applies downward .

stainless steel sheet bending machine

Mild steel sheet. 18 or 20 or 22 gauge. About $30 for a 4'*4' piece. 22 gauge for new Hondas. 18 for old vw pans. 20 gauge for old vw bodies. It's a personal preference. 22 is way easier to bend than 18, but 18 will take more weld without blowing through. The stuff I get is light gray with an oil film, but black steel would work too.

roller bending sheet metal|manual sheet metal rollers