sheet metal forming with 3d printed dies Press-forming is a versatile metal forming technique that can quickly and easily . Just moved into a house that has one of the old old BT Junction Boxes from the 60's / 70's and it has an old master socket feeding off from it. I have an order placed for .

0 · 3d printing sheet metal

1 · 3d printed sheet metal forming

2 · 3d printed dies for sheet metal

3 · 3d printed cast dies

What's a Madison bar and an OWC clip and a gem box? Madison bars are slang for cut in box support. Gem box is just an old work box. Use them all the time for walls and cabinets and have never had any issues with inspectors in our area anyway. Thanks, I'll make sure to send one of my guys down there.

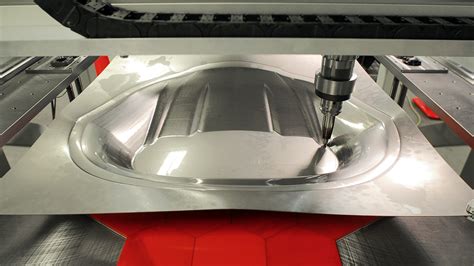

Using 3D printed forms to bend sheet metal isn’t exactly new. We’ve seen several people create custom dies for their brakes, and the results have shown the concept has merit .Press-forming is a versatile metal forming technique that can quickly and easily . I improve over my previous designs by making a tool with a moving action as well as fixing a major design flaw. I also demonstrate a more complicated forming operation with many features made in. 3D Printed Sheet Metal Repair and Forming Dies. STL's and links @ http://fpfdesigns.com/ Irwin Quick Grip Clamp: https://amzn.to/3WYer9k Gray PLA: https://amzn.to/3E3tXbC Outro .

Learn how to use 3D printed tooling for sheet metal forming and dimple dies. Plus, learn which materials to use and get tips and tricks for creating your own.

Experimental Case Study: Sheet Metal Forming With 3D Printed Dies. Materials and Equipment. Forming a Replacement Blade Guard. Design Considerations. Introduction. Traditional metal manufacturing techniques include forming, casting, molding, joining, and machining. In today's episode, I'm seeing whether 3D Printed PLA dies can hold up to forming various gauges of mild steel, stainless steel, and aluminum. This is comple.

Posted in Tool Hacks Tagged 3d printed, composite, epoxy, forming, hydraulic press, infill, metalworking, press-forming, resin, sheet metal, tooling Post navigation ← Putting The Magic Smoke .FORMLABS: How to Do Rapid Tooling for Sheet Metal Forming With 3D Printed Dies 5 Sheet metal forming is an equipment-intensive operation, and requires machinery and specialized tools that are part-dependent . As shown above, the tool—also referred to as the form or die—is the part of the forming machine acting to bend the sheet .

3d printing sheet metal

Forming Sheet Metal using a 3D Printed Die . So I put up a post the other day on 3D printing a Die and using it to form sheet metal, now this is what I have come up with: Fusion 360 Design of whole process completed. So I started off with my bent part, as follows: Bent Part.Been doing some experimentation with 3D printed press dies and used the result to press this repair panel for my 1970 Charger. Press dies are printed with low infill and no bottom and filled with polyester. I also made holders for the dies that fit .This could help sheet metal die design guide.I’m guessing with plastic you’d only be able to bend the thinner material. Fusion may have an FEA plugin as well where you can make your CAD model, enter material properties of the plastic (you may have to look up what modulus of elasticity people have found experimentally for printed parts), add predicted loads based on how much .

Using FDM 3D printing technology can be a great way to produce metal forming tools, such as those used for hydroforming an rubber pad pressing. In this technical application guide, we go through the step-by-step procedures of 3D printing these tools and utilizing them for prototyping, part repair, and custom parts.

Custom Tooling and Fixturing: Creating tools for sheet metal forming, such as dies for stamping or bending, is expensive and time-consuming. With 3D printing, you can precisely produce these parts to your specifications, cutting costs and wait periods. You can make quick adjustments and iterations as needed, since the process is agile and .

METAL FORMING With a 3D Printer: For this project, we are replicating automotive armrest brackets. To do so, we are using our 3D printers to make the dies. We will then use a 6-ton press to form the shapes. . We cut the sheet metal to the same width as the original piece, but cut it extra long to make up for the loss of length from the bends. . Round beads serve to stabilize metal sheets. The creation of such circular beads can be made very easy with a 3D printed dimple die.When printing with PLA or. 14 guage steel, pretty impressive. For reference thats about what cars used to be made of, and as a ex body work tech I used to love working on them, now its closer to 20-22 guage, paper thin. When Jibeworks needs something new we innovate - it's what we do. In this video check out the white 3D printed sheet metal die we printed to create the perfe.

( die + sheet metal stock) Outsourced 3D printed tool: Pressing machine, metal cutting equipment: 6 business days: 0 (0 die + sheet metal stock) 0 (0 die + sheet metal stock) Outsourced metal tool: Pressing machine, metal cutting equipment: 25 business days: 0 (0 die + sheet metal stock) Pilot Demonstration of Hot Sheet Metal Forming Using 3D Printed Dies Materials (Basel). 2021 Sep 30;14(19):5695. doi: 10.3390/ma14195695. Authors Jaume Pujante 1 . This work describes a pilot experience in 3D-printed press hardening tools, comparing the performance of additive manufactured Maraging steel 1.2709 to conventional wrought hot . ( die + sheet metal stock) Outsourced 3D printed tool: Pressing machine, metal cutting equipment: 6 business days: 0 (0 die + sheet metal stock) 0 (0 die + sheet metal stock) Outsourced metal tool: Pressing machine, metal cutting equipment: 25 business days: 0 (0 die + sheet metal stock)3D printing solutions for health care Industrial-grade polymer 3D printing . technology eliminates the need for a traditional stamping press or custom tools, molds, and dies – delivering sheet metal forming that is accessible, flexible, and cost-effective, even at low volumes. Preliminary Specs. Max Sheet Size (XY) 1 600 mm x 1200 mm

It has been shown that the combination of sheet metal hydroforming, along with 3D Printed plastic tooling, can allow a significant reduction in cost and investment for prototype sheet metal production. . Large capacity presses enable rapid closing of die sets and forming of sheet metal without needing to wait for fluid pressurization required . The objective of the study was to compare the die wear of the coated 3D-printed tools to the die wear of the coated D2 tool steel during room-temperature stamping of the steel sheet. The strip for forming of the U-bend shape was blanked from a . Using an ABS plastic 3d printed die set to form a 22 gauge stainless steel blank into an A/C line retaining bracket. 3d print settings: 265c extruder temp, . I designed and printed these louver forming tool to form 18ga stainless steel sheet metal parts. Please support my channel to help me make more videos and pr.

I've asked the question "How do you emboss metal?" to a few other "famous" YouTubers.what are the details? I received no response. So when the need arose.

ABS die for low volume production of simple bracket made out of 0.5mm sheet metal.

my experiences with using 3d prints to form sheet metal 3D printed metal forming dies allowed East/ West significantly drive down the cost of making metal forming dies. . Part of East/West’s production involves fabricating sheet metal components. One particular customer job required the use of a machined forming die. However, the die was found damaged just before the job was started. . After we completed the design, it was time to print the dies. We printed this in PLA. Since we were after strength, we printed it with 10 layers on top and bottom and used 80% infill with triangle infill shape. Print time is for the two sides required just over 8.5 hours of printing. It was printed at .34mm layer height.

customized cnc machining service

customized brass cnc machining parts

Outdoor Electrical Junction Boxes – In construction, infrastructure, and telecommunications, use an IP-rated enclosure to protect electrical connections from the weather and even temporary immersion during heavy rain or flooding.

sheet metal forming with 3d printed dies|3d printed sheet metal forming