manufacturing sheet metal part During the fabrication process, the sheet metal is usually first punched and cut in different ways and then followed by forming processes to make a nearly finished and realized . See more Each battery cell voltage is monitored by control modules and appropriate control methods are applied to keep voltage deltas between cells to a tight tolerance. The junction box controls the high-voltage connections for the charging system, inverter/motor, and battery pack.

0 · sheet metal manufacturing process types

1 · sheet metal fabrication capabilities

2 · sheet metal diagram fabrication

3 · customized sheet metal fabricating price

4 · custom sheet metal manufacturers

5 · custom metal parts manufacturers

6 · custom metal fabrication small parts

7 · cheap sheet metal rapid prototype

Nema Enclosures designs and manufactures NEMA rated electrical enclosures in the following NEMA standards: NEMA 1. NEMA 3RX. Enclosures constructed for either indoor or outdoor use to provide a degree of protection to personnel .

Get an introduction to sheet metal fabrication. This section explains the sheet metal fabrication process, how precision sheet metal fabrication differs, the main advantages and disadvantages, as well as its common applications. How does sheet metal fabrication work? There are several different ways to . See more

In this section, we’ll cover and compare fourteen different types of sheet metal fabrication including cutting, forming, stamping, holemaking and threading. See more

There are numerous ways of effectively cutting through sheet metal. This section will briefly cover the many different approaches to cut through sheet metal, split into two key . See moreIn this section we’ll cover the best practices to follow when designing for sheet metal bending and laser cutting ー the two sheet metal fabrication services we offer. We’ll begin . See moreDuring the fabrication process, the sheet metal is usually first punched and cut in different ways and then followed by forming processes to make a nearly finished and realized . See moreOur online sheet metal fabrication service enables you get a quote in minutes and have your parts delivered in days. We offer 3D visualized Design for Manufacturability (DFM) feedback to help you manage project costs and .

sheet metal manufacturing process types

See how B & B Manufacturing creates a Sheet metal part from start to finish!B and B Manufacturing is a full service sheet metal shop, in Forest Hill, Marylan.

Sheet metal fabrication is a critical part of manufacturing, and optimising costs in its design and production will improve competitiveness and profitability. By implementing cost-effective strategies from the outset, you can .Precision Metal Fabrication in South Africa. Milga Steel Fabrication is dedicated and passionate about using advanced CNC Machine equipment to produce high quality precision metal fabrication parts. We offer premium quality sheet metal .

Tolerances refer to deviations from perfect accuracy when manufacturing sheet metal parts. Even though the vast majority of modern machines produce pieces with extreme accuracy, it doesn’t mean that the deviations will be 100% avoided. So, during the creation of the blueprint, it is very important to consider such deviations and include . Sheet metal fabrication is a subtractive manufacturing process that forms parts from thin metal sheets. Engineers often choose sheet metal parts for their high strength-to-weight ratio, durability, and versatility. This guide will provide a comprehensive overview of precision sheet metal fabrication techniques, applications, and best practices.

sheet metal fabrication capabilities

Material removal. Laser cutting Laser-focused light beam for precision cuts into sheet metals. Punching A hole-forming process achieved using a punch and a die to force a hole into a metal sheet sandwiched between. The size and shape of the hole depending on the die. Machining Use of CNC machines, tool paths, and cutting tools to make highly accurate and precise cuts until .

Sheet metal fabrication is a subtractive manufacturing process that forms parts from thin metal sheets. Engineers often choose sheet metal parts for their high precision and durability, especially for end-use applications like chassis, enclosures, and brackets.Importance of Sheet Metal Parts in the Automotive Industry. Automotive sheet metal parts created by metal sheet stampings serves many purposes within vehicles, impacting their aesthetics, structural integrity, safety, and overall performance.These parts can range from simple stamped components like fenders and hoods to complex structural elements like chassis components .We make it as easy as possible for you by offering a one-stop source for custom, fully finished precision sheet metal parts. Choose from a variety of materials, hardware, fasteners, and powdercoat colors to fully finish your custom sheet metal part. Add graphics such as a logo or labeling with our direct digital printing and silkscreen services. Conventions of sheet-metal part drawing The conventions for sheet-metal part drawing are as follows: solid lines represent the boundaries of the part and the dotted lines or dashed lines represent [~ Punch-hoSder ! 2 $ 4 Fig. 1. Bending operation. ( Design and manufacturing of sheet-metal parts C.-H. WANG and D. A. BOURNE 283 Fig. 2.

sheet metal diagram fabrication

Expertise Furniture Manufacturing from Galaxy. Our sheet metal fabrication services encompass a wide range of furniture components. Whether you need metal frames, brackets, legs, or decorative accents, we have the expertise and capability to produce components that perfectly complement your furniture designs. . Beyond individual parts, we . A large number of sheet metal parts with different shapes and different sizes have been formed through the flexible manufacturing technology of DDF. Fig. 4 , Fig. 5 present sheet metal parts manufactured by two DDF systems, the digitized-die in the first system is comprised by 28×20 punches and that in the second 16×12 punches.

Redstone Manufacturing’s steel and aluminum sheet metal fabrication services are an inexpensive option for your manufacturing needs. We offer custom sheet metal fabrication with machines that precisely cut, stamp, and form metal sheets into a completed part. Sheet metal fabrication allows for the production of a variety of part types, both .Sheet metal fabrication is the process of forming customized parts from entire sheets of metal. These parts are known to be stronger than other fabrication methods, making the process ideal for creating durable frames and chassis. When combined with NEFM’s welding and finishing services, sheet metal fabrication can produce the highest-quality .

CAD Part Design. A sheet metal toolbox is a feature of many CAD software such as Solidworks that allows users to design and manipulate sheet metal parts. Sheet metal toolbox also helps users to flatten sheet metal parts, generate drawings, and export data for manufacturing. For a simple example, see:

Sheet Metal Manufacturing. Before you start designing with sheet metal, it’s important to study the actual process by which the parts get made. . Once you understand how sheet metal parts are created, you can begin designing sheet .Sheet Metal Parts . Our plant is equipped with machinery that can produce a wide range of sheet metal components, including top-of-the-range electric and hydraulic brake presses, a CNC punch press and other sheet metal .Tolerances of Machined and Sheet Metal Parts Xometry's Manufacturing Partner Network makes thousands of machines available to make your part at the click of a mouse. Since the minimum requirement to machine a part is a solid CAD file, we offer these general tolerances and guidelines (also found in our Manufacturing Standards ). 5. • Aluminum is also a popular metal used in sheet metal due to its flexibility, light weight, and cost effectiveness • Most common Grade 3003- H14 is fairly strong, while maintaining the same formability and low cost. It is corrosion resistant and weldable. It is often used in stampings, spun and drawn parts, and fan blades • Brass is an alloy of copper, which is widely .

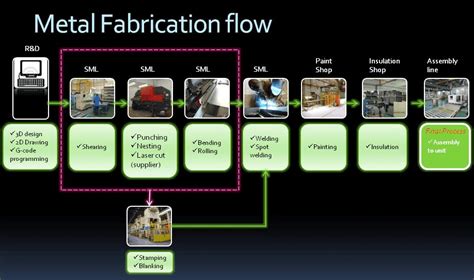

As one of the custom sheet metal services companies from China, Metalcax offers precision and cheap rapid prototyping products and manufacturing service for your new product development. With dedicated project management and extensive experience in Prototyping , Pre-Series and Low Volume Production of sheet metal parts, we serve the Electronics . The process of fabricating sheet metal parts requires a lot of work and effort. At Creatingway, we understand this requirement thus desire to deliver your part safely. . Creatingway is concentrating on CNC machining manufacturing, prototype machining, low-volume manufacturing, metal fabrication, and parts finishing services, providing you the . The process of computer-aided design and manufacturing of sheet metal parts starts with computer-aided design, goes through numerical simulation unfolding, nesting, cutting, stamping, bending, and other procedures, and ends with the computer automatically outputting the part’s process route, operation content, tooling motion trajectory (tool .K.K. Metal Processing Sdn. Bhd. specializes in the flexible manufacturing of precision sheet metal parts since 1974. We have served the banking, laboratory, printing, furniture, air-conditioning, food processing, power technologies, construction, electrical and electronic, water works and many other industries for over 30 years.

customized sheet metal fabricating price

With their expertise in precision manufacturing, Trupart Mfg delivers high-quality aerospace sheet metal components that meet the stringent requirements of the aerospace industry. Their skilled team of engineers and craftsmen work diligently to ensure every piece is meticulously crafted to exact specifications, ensuring precision fit and . Sheet metal forming is a process used in many industries to make metal parts from thin metal sheets. It’s actually one of Xometry's most popular manufacturing methods. Our customers use the Xometry Instant Quoting Engine® to get automatic quotes on everything from simple brackets to aircraft parts and sheet metal assemblies. In this article .

Sheet metal tolerance is a specified range that allows for variations in the design dimensions of parts. The manufacturing tolerances range defines the upper and lower limits of the variable design size of the workpiece. Tolerances are critical for ensuring the precision of sheet metal parts, and widely used in sheet metal fabrication. The .

Sheet metal parts often require multiple manufacturing processes to produce correctly. Because of this added complexity sheet metal drawings can be particularly tricky to create. This article will focus on how to prepare accurate and easy to interpret sheet metal drawings so that your parts come out in spec every time.

custom sheet metal manufacturers

custom metal parts manufacturers

For a gray house, there are many roof shingle colors that work with this neutral hue. Whether you have painted your home’s exterior a light or dark gray shade, any of our suggested roof color ideas will complement your home’s brick or stone facade.

manufacturing sheet metal part|customized sheet metal fabricating price