k factor for aluminum sheet metal The SkyCiv K-Factor for Sheet Metal is a free tool designed to help structural engineers and sheet metal fabricators who need to understand the precision and effects of their sheet metal bending designs. DXF files, short for Drawing Exchange Format, are one of the most widely used file types in CNC machining. Developed by Autodesk, DXF files allow for the exchange of 2D drawings between different CAD software platforms.

0 · k factor sheet metal bending

1 · k factor for 5052 aluminum

2 · k factor explained

3 · k factor calculator statistics

4 · k factor calculator excel

5 · how to measure k factor

6 · how to calculator k factor

7 · bend allowance k factor chart

Bright yellow shades are a great way to make your stainless steel appliances shine with warmth. This cheerful color works well with light to medium tones of grey. For a bold and bright kitchen design, go for yellow cabinets, checkered yellow tiles for the flooring and a grey backdrop as shown here.

Use our K-factor calculator to determine the position of the neutral axis in the sheet of metal you are planning to bend.

A K-Factor will typically range between 0 and .5 for standard materials and thicknesses though smaller and larger K-Factors are possible. To help you begin I’ve included a K-Factor Chart below which contains common K-Factor starting .

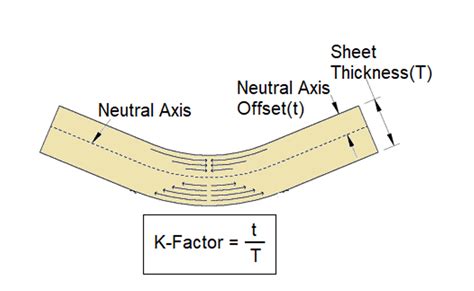

In sheet metal, the K-factor is the ratio of the neutral axis to the material thickness. When a piece of metal is being formed, the inner portion of the bend compresses while the . The SkyCiv K-Factor for Sheet Metal is a free tool designed to help structural engineers and sheet metal fabricators who need to understand the precision and effects of their sheet metal bending designs. Knowing the k-factor formula is essential in order to bend any kind of sheet metal correctly; in fact, it varies according to the type of material to be deformed. What is the k-factor? The k-factor indicates the behaviour of the .

K-factor is a crucial parameter used in sheet metal bending calculations. It represents the location of the neutral axis in a bent sheet metal part. The neutral axis is the theoretical line within the . Finding the correct minimum bend radius for steel or aluminum plate requires a little research and should include data from your material supplier and another critical ingredient in your k-factor gumbo: whether you are .Mathematically k factor value is equal to the ratio of position of the neutral axis and sheet thickness. In this article, we will discuss sheetmetal bend deduction, bend allowance, K-factor, Y-factor, and sheet metal flat pattern calculations.The sheet metal k factor is a crucial parameter used during the bending and folding process of metal sheets. The degree of deformation of the metal sheet upon bending is indicated and .

k factor sheet metal bending

The K-Factor is a geometric constant used in sheet metal fabrication that relates the position of the neutral axis to the material’s thickness. This factor helps in determining how much the metal will stretch during bending. . For example, softer materials like aluminum may have different K-Factors compared to harder materials like steel .If the value of sheet metal K factor and bending flange length is known. Sheet Metal flat length can be calculated in the following three steps. Step-1: Calculate the value bend allowance for the required sheet metal bend by using the .Y factor and K factor represent part constants used in formulas to calculate the developed length of flat sheet metal required to make a bend of a specific radius and angle in a design. Y factor and K factor are defined by the location of the sheet metal .

k factor for 5052 aluminum

Use one of the listed K-Factor calculators and measurement of a sample bent part: K Factors Autodesk Inventor; Inventor K Factor Calculator; Manually calculate the K-Factor using the measure of sample sheet metal parts that were bent using the following formula: Question: We currently bend A36 material thicknesses from 16 ga. up to 1 in. and, occasionally, various thicknesses of stainless steel and aluminum. We recently added a new press brake and are now faced with the challenge of recalculating our k-factor values and creating new DXF flat patterns of all bent parts.

So, now you have a formula for the BA—but where’s the k-factor? It’s hiding in that 0.0078 value, which is π/180 × k-factor. To arrive at 0.0078, the equation uses a k-factor of 0.4468, a commonly used factor that’s the default for many CAD systems.Shop our selection of aluminum sheet metal k-factor in the Hardware Department at The aluminum metals Online. Welcome! aluminum metals Online. Fr Es En +86-0371 65621391 [email protected]

Unfolded flat size: The total length of the sheet metal when flattened; K-factor: The location of the neutral axis relative to the inside of the bend; Y-factor: The distance from the inside of the bend to the neutral axis . Some materials, particularly certain aluminum alloys and high-strength steels, exhibit strain rate sensitivity. This . For example, for 304 stainless steel, the percentage ranges from 20% to 22%, but for H-series soft aluminum, the range is between 13% and 15%. . K-factor and Y-factor in sheet metal both look at how bending affects the material and how much bending the metal will allow. When sheets of metal bend, the top surface compresses and the bottom expands.K-factor, bend allowance/deduction, and outside setbacks all affect sheet metal design. . and outside setbacks all affect sheet metal design. Learn about them to avoid issues during your design process. . roughly 3-1/2 in. (88.9mm) square by 0.083 in. (2.1082mm) thick—about the same as a piece of 12-gauge brass or aluminum. Now, bend it .

The K-factor is determined by the physical properties of the material, bending method, bending angle, and other factors. Material Properties: it typically ranges between 0.30 and 0.50.In general, the K-factor of soft copper or soft copper materials is 0.35, the K-factor of materials such as semi-hard copper or brass, mild steel and aluminium is 0.41, and the K . The K factor is a key metric in many fields like statistics, engineering, and manufacturing. This article will explore what the K factor is, how it’s calculated, and its uses. It’s important for data analysts, electrical engineers, and sheet metal workers to know about the K factor. It helps them make better decisions and improve their work.I'm pretty sure this isn't done and k-factor only applies to sheet metal bending, but is there an equivalent "stretch" type calculation that can be applied to tubing? . Yep, Forming and Bending Aluminum by Kaiser Aluminum, 1st ed from 1954. Abe Books looks like 10 USD for a "very good" copy of it. Reply reply More replies More replies.

Uses of Sheet Metal K Factor. The role of the K factor in precision Bending. Shengen’s precision bending operations rely on the K Factor. The K Factor is used to calculate the bend allowance, which is crucial for maintaining the accuracy of dimensions .Hi I’m new to sheet metal design, can somone explain in simple terms what bend deduction, k factor is etc. and how it’s calculated? Guy who’s training me seems ignorant and rather than explain gave me a list of figures to use, he said use 4mm bend deduction for 2mm thickness, and 5.5 for 3mm thickness which is what we commonly use. Hi All, I found out that inventor had to figure the K factor for every plate thickness ie. 4mm, 5mm, 6mm, 8mm etc. It creates a radius for every bend thus when you create the flat pattern, in real life fabrication the flat pattern turns out to be wrong. Issues will arise in the workshop as what I've come up is have 2 separate K factor / Spline Factor setting.

sheet metal seat pan

Leveraging the K-Factor in Sheet Metal Fabrication for Enhanced Manufacturing OutcomesPrecision is paramount in sheet metal fabrication. Accurately bending sheet metal into desired shapes directly influences the .

programs to produce accurate sheet-metal work. Many CAD programs, however, also work out bend allowances automatically by using K-factor calculations. (Or Y-factor in the case of Pro-E where Y-factor = K-factor * / 2). Bend allowances are calculated using a K-factor as follows: BA= (R + KT) A/180 where: BA = bend allowance R = inside bend radius The biggest difference between the k-factor and the y-factor in sheet metal bending is that the y-factor takes the internal stresses of the material into account more so than the k-factor does. This means that calculations involving the y-factor are slightly more accurate than those involving k-factor, but also quite a bit more complicated and .I work on Solidworks Sheet Metal for designing sheet metal boxes, plates, hoppers,etc. . We have done tests on aluminum/ mild steel and Stainless. 1mm to 12mm Vee sizes 6 to 100. We have these laid out in charts with corresponding bend deductions and k factors I can give you a link to them if they will be useful. I also can supply the gauge .

In Machinery’s Handbook, the K-factor for mild cold-rolled steel with 60,000-PSI tensile strength is 0.446 inch. This K-factor is applied as an average value for most bend allowance calculations. There are other values for stainless and aluminum, but in most cases, 0.446 in. works across most material types.

K is the K factor. T is the sheet metal thickness. A is the bend angle in degrees. Practical Example of K Factor Calculation. Let’s consider a practical example to illustrate the use of the K factor in sheet metal bending. Example: Sheet Metal Thickness (T) = 0.0625 inches Inside Bend Radius (R) = 0.125 inches Bend Angle (A) = 90 degreesK-Factor is a ratio that represents the location of the neutral sheet with respect to the thickness of the sheet metal part. When you select K-Factor as the bend allowance, you can specify a K-Factor bend table. The SOLIDWORKS application also comes with a K-Factor bend table in Microsoft Excel format.

The bend allowance/bend deduction of the sheet metal (specified in K-factor) By configuring and utilizing a sheet metal gauge table, we can speed up the process of selecting the correct wall thickness (based on gauge value) and selecting the correct bend radius (based on available tooling).We can also automate the process of selecting the .

The SkyCiv K-Factor Calculator for sheet metal is pretty straightforward and requires just a few simple inputs via the left panel, mainly: Material Thickness (T): The initial thickness of your metal sheet before the bend Inner Radius (Ri): This is the radius on the inside curve of the bend.A smaller radius implies a sharper bend Ever wonder what "K-Factor" means when defining your Sheet Metal Rules in Fusion 360? This Quick Tip provides more insight on how the K-Factor is used to det.

You also asked about the K-factor, which happens to be one of the most commonly misused terms in precision sheet metal. A K-factor, while a very important factor for calculating bend elongation, is just that—a factor. The K-factor itself is a multiplier used to calculate the new position for the relocated neutral axis after forming.

k factor explained

Normally 18-gauge sheet metal is used for body panels. Mild steel gets priority here and some racers choose 20-gauge sheet metal over 18 gauge. Then they start working to lighten mechanisms up.

k factor for aluminum sheet metal|k factor explained