advantages and disadvantages of sheet metal In this article, we’ll give you the lowdown on sheet metal forming, including the various processes, suitable materials, and its pros and cons. What is Sheet Metal Forming? Also known as sheet metal fabrication, sheet metal . You don't need a wire to ground the switch, the mounting screws satisfy the requirement when used with metal boxes, and there is an exception that allows you to not satisfy grounding requirements if no grounding means exists for replacement switches.

0 · what is sheet metal used for

1 · what is a sheet metal

2 · sheet metal forming disadvantages

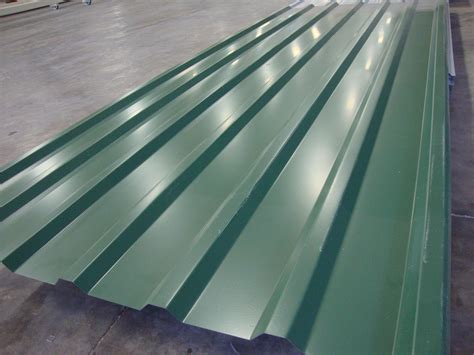

3 · sheet metal construction materials

4 · sheet metal construction

5 · how does sheet metal work

6 · examples of sheet metal

7 · advantages of sheet metal

You can find the gauge to mm / inch conversion for sheet metal by the chart below. Or you can Download the Sheet Metal Gauge Size Chart PDF. (Click here) How many mm is 8 gauge? For different materials of steel, the same gauge will also correspond to different mm. What is 10 gauge in mm? What is 16 gauge thickness in mm?

In this article, we’ll give you the lowdown on sheet metal forming, including the various processes, suitable materials, and its pros and cons. What is Sheet Metal Forming? Also known as sheet metal fabrication, sheet metal . Advantages and Disadvantages Pros. In my experience, working with sheet metal offers several advantages. First, it provides a remarkable weight-to-strength ratio, making it ideal for various industries such as aerospace, .Get an introduction to sheet metal fabrication. This section explains the sheet metal fabrication process, how precision sheet metal fabrication differs, the main advantages and . Although sheet metal forming presents some challenges, its advantages in material strength, cost-effectiveness, production efficiency, variety of shapes and sizes, .

Sheet metal fabrication is commonly used in industrial and automotive projects due to its strength and durability. However, no production process is perfect. Before settling on a process, it’s essential to familiarize . Sheet metal enclosure manufacturing involves many different sheet metal forming processes such as roll forming, stamping, peen forming and more. This list compares the good and bad of each process so you can determine .Metal Forming is a broad set of manufacturing techniques tha used to create metal parts or machined workpieces by converting raw materials into finished goods. We apply forces such as tension, compression, shear, and others to .Advantages and Disadvantages of Forming Operations. Learn more now!

Metal forming is a vital manufacturing process involving the manipulation of metal sheets, bars, or billets to achieve desired shapes and dimensions. Advantages and disadvantages of Metal forming Metal forming processes offer numerous benefits regarding material efficiency, production rates, and mechanical properties, making them ideal for large-scale manufacturing. In this article, we’ll give you the lowdown on sheet metal forming, including the various processes, suitable materials, and its pros and cons. What is Sheet Metal Forming? Also known as sheet metal fabrication, sheet metal forming uses metal sheets to make various products and components. Advantages and Disadvantages Pros. In my experience, working with sheet metal offers several advantages. First, it provides a remarkable weight-to-strength ratio, making it ideal for various industries such as aerospace, automotive, and construction.

what is sheet metal used for

Get an introduction to sheet metal fabrication. This section explains the sheet metal fabrication process, how precision sheet metal fabrication differs, the main advantages and disadvantages, as well as its common applications.

Although sheet metal forming presents some challenges, its advantages in material strength, cost-effectiveness, production efficiency, variety of shapes and sizes, surface quality and precision, environmental impact, and degree of automation make it a highly recommended manufacturing option. Sheet metal fabrication is commonly used in industrial and automotive projects due to its strength and durability. However, no production process is perfect. Before settling on a process, it’s essential to familiarize yourself with both the benefits and drawbacks that it provides.

Sheet metal enclosure manufacturing involves many different sheet metal forming processes such as roll forming, stamping, peen forming and more. This list compares the good and bad of each process so you can determine the proper one for your own unique requirement.Metal Forming is a broad set of manufacturing techniques tha used to create metal parts or machined workpieces by converting raw materials into finished goods. We apply forces such as tension, compression, shear, and others to the deformed material in this process.Advantages and Disadvantages of Forming Operations. Learn more now! Metal forming is a vital manufacturing process involving the manipulation of metal sheets, bars, or billets to achieve desired shapes and dimensions.

what is a sheet metal

Advantages and disadvantages of Metal forming Metal forming processes offer numerous benefits regarding material efficiency, production rates, and mechanical properties, making them ideal for large-scale manufacturing.

In this article, we’ll give you the lowdown on sheet metal forming, including the various processes, suitable materials, and its pros and cons. What is Sheet Metal Forming? Also known as sheet metal fabrication, sheet metal forming uses metal sheets to make various products and components. Advantages and Disadvantages Pros. In my experience, working with sheet metal offers several advantages. First, it provides a remarkable weight-to-strength ratio, making it ideal for various industries such as aerospace, automotive, and construction.

cnc machine doors

Get an introduction to sheet metal fabrication. This section explains the sheet metal fabrication process, how precision sheet metal fabrication differs, the main advantages and disadvantages, as well as its common applications. Although sheet metal forming presents some challenges, its advantages in material strength, cost-effectiveness, production efficiency, variety of shapes and sizes, surface quality and precision, environmental impact, and degree of automation make it a highly recommended manufacturing option.

Sheet metal fabrication is commonly used in industrial and automotive projects due to its strength and durability. However, no production process is perfect. Before settling on a process, it’s essential to familiarize yourself with both the benefits and drawbacks that it provides. Sheet metal enclosure manufacturing involves many different sheet metal forming processes such as roll forming, stamping, peen forming and more. This list compares the good and bad of each process so you can determine the proper one for your own unique requirement.Metal Forming is a broad set of manufacturing techniques tha used to create metal parts or machined workpieces by converting raw materials into finished goods. We apply forces such as tension, compression, shear, and others to the deformed material in this process.

Advantages and Disadvantages of Forming Operations. Learn more now!

sheet metal forming disadvantages

sheet metal construction materials

sheet metal construction

how does sheet metal work

What gauge of metal are military ammo boxes? Military ammo boxes are typically made from steel that is around 14 gauge, which provides the necessary strength and durability to protect the ammunition inside.

advantages and disadvantages of sheet metal|how does sheet metal work