common junction box sizes Correct fill capacity: The junction box should be large enough to contain the wires. . Let us kick off the discussion by establishing a formal definition of metal fabrication. It is the process of building metal structures through processes like cutting, bending, and assembling. Any manufacturing method that fits this short definition is .

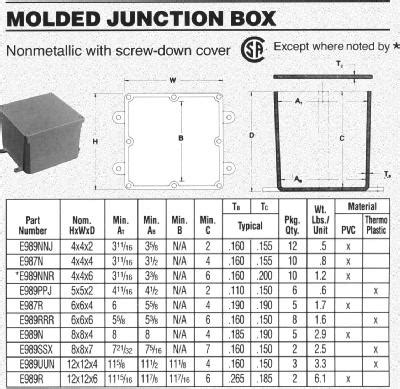

0 · pvc junction box size chart

1 · nec junction box size chart

2 · junction box standard sizes

3 · junction box size in mm

4 · junction box size calculator

5 · junction box dimensions standard

6 · junction box dimension

7 · different types of junction boxes

A gang box, also known as a junction box or electrical box, is a container used in construction and electrical work to house electrical connections, switches, outlets, and other components. It provides a safe and organized enclosure for electrical wiring and helps protect against electrical hazards .

A junction box is not a special type of box but any standard electrical box used to enclose wire splices. The most commonly used box for junctions is a 4-inch square box (either metal or strong plastic), which offers ample space for making wire connections with multiple .When nailing the box, use light, careful blows rather than heavy swings of the .

When the box is attached to the drywall, not the studs: Exposed locations or stud .Once the hole is cut in the wall for the box, feed the cable (or cables) out through .Correct fill capacity: The junction box should be large enough to contain the wires. .To install this type of clamp, insert the threaded end into a knockout hole in the .

pvc junction box size chart

Box Size. Wires, receptacles and switches need adequate space. Crowded boxes can damage wires, resulting in a fire or shock hazard. You can use the chart below to . Use this junction box sizing calculator to determine the recommended dimensions of a junction box depending on the number of straight and angle pulls entering it and meet the National Electrical Code®. A junction box is not a special type of box but any standard electrical box used to enclose wire splices. The most commonly used box for junctions is a 4-inch square box (either metal or strong plastic), which offers ample space for making wire connections with multiple wires or .

Wondering how to size a junction box? Find out how to use the NEC code to determine the size of the junction box that your application requires. Junction boxes are must-have units at home as they protect against electrical issues. Here are a few of the most common junction boxes and where to use them. Box Size. Wires, receptacles and switches need adequate space. Crowded boxes can damage wires, resulting in a fire or shock hazard. You can use the chart below to calculate the required box size. Add up the numbers for the correspond- ing components in the box to find how many cubic inches you’ll need. Use this junction box sizing calculator to determine the recommended dimensions of a junction box depending on the number of straight and angle pulls entering it and meet the National Electrical Code®.

There is a huge selection of electrical boxes, varying by size, shape, mounting device, and composition. One of the first distinctions to note is that of new work boxes and remodel or cut-in boxes. The sizing requirements for pull boxes, junction boxes, handhole enclosures, and conduit bodies exist to prevent conductor insulation damage. Those requirements are in 314.28, and they apply to all conductors 4 AWG and larger ( Fig. 1 ).Box Selection: Choose a junction box with a minimum volume of 22.5 cubic inches. A standard 4x4x2-1/8 inch box typically provides 21 cubic inches, which would be insufficient. Therefore, a larger box, such as a 4x4x2-1/2 inch box with 24 cubic inches, would be appropriate. Compliance: Always ensure that the chosen box meets NEC requirements.

Most electricians know by experience what size box to choose for each application, but with larger devices with lots of wiring or in borderline cases, it may be necessary to perform box-fill calculations. These are covered in National Electrical Code (NEC) sections 314.16 (A) and 314.16 (B). The most common junction boxes are 4 or 6 terminal junction boxes. That said, the exact number of terminals will always depend on how many connections you need to make. When choosing an electrical junction box make sure that you have enough terminals for each pair of wires you wish to connect.

A junction box is not a special type of box but any standard electrical box used to enclose wire splices. The most commonly used box for junctions is a 4-inch square box (either metal or strong plastic), which offers ample space for making wire connections with multiple wires or .

Wondering how to size a junction box? Find out how to use the NEC code to determine the size of the junction box that your application requires. Junction boxes are must-have units at home as they protect against electrical issues. Here are a few of the most common junction boxes and where to use them. Box Size. Wires, receptacles and switches need adequate space. Crowded boxes can damage wires, resulting in a fire or shock hazard. You can use the chart below to calculate the required box size. Add up the numbers for the correspond- ing components in the box to find how many cubic inches you’ll need.

Use this junction box sizing calculator to determine the recommended dimensions of a junction box depending on the number of straight and angle pulls entering it and meet the National Electrical Code®.There is a huge selection of electrical boxes, varying by size, shape, mounting device, and composition. One of the first distinctions to note is that of new work boxes and remodel or cut-in boxes. The sizing requirements for pull boxes, junction boxes, handhole enclosures, and conduit bodies exist to prevent conductor insulation damage. Those requirements are in 314.28, and they apply to all conductors 4 AWG and larger ( Fig. 1 ).Box Selection: Choose a junction box with a minimum volume of 22.5 cubic inches. A standard 4x4x2-1/8 inch box typically provides 21 cubic inches, which would be insufficient. Therefore, a larger box, such as a 4x4x2-1/2 inch box with 24 cubic inches, would be appropriate. Compliance: Always ensure that the chosen box meets NEC requirements.

Most electricians know by experience what size box to choose for each application, but with larger devices with lots of wiring or in borderline cases, it may be necessary to perform box-fill calculations. These are covered in National Electrical Code (NEC) sections 314.16 (A) and 314.16 (B).

nec junction box size chart

junction box standard sizes

junction box size in mm

britannia sheet metal

Sheet metal fabrication is forming metal into thin, flat sheets. This can be done through various methods, including stamping, cutting, bending, etc. Sheet metal is used in many applications, from automotive body panels to electronic enclosures.

common junction box sizes|junction box standard sizes